Coarse-denier high-strength spun-bonded non-woven fabrics and preparation method thereof

A spun-bonded non-woven fabric with high strength technology, which is applied in the direction of melt spinning, non-woven fabrics, textiles and papermaking, and can solve the problem of low breaking strength of spun-bonded non-woven fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a method for preparing a coarse denier high-strength spunbonded nonwoven fabric, comprising the following steps:

[0021] a) Crystallize and dry PET with an intrinsic viscosity of 0.8 to 1 to obtain PET slices;

[0022] b) Melting and extruding, filtering, spinning, cooling and drawing the PET chips in order to obtain PET fibers; when spinning, the capillary pores of the spinneret are 0.6 mm to 0.9 mm;

[0023] c) laying the PET fibers into a web, and performing reinforcement treatment to obtain a coarse denier high-strength spunbonded nonwoven fabric.

[0024] The invention uses PET with an intrinsic viscosity of 0.8-1 as a raw material, which makes it possible to spin through a large-diameter spinneret, thereby obtaining a coarse denier and high-strength spun-bonded non-woven fabric with high breaking strength. In the present invention, the intrinsic viscosity of the PET is more preferably 0.9.

[0025] In the present invention, firstly, PET w...

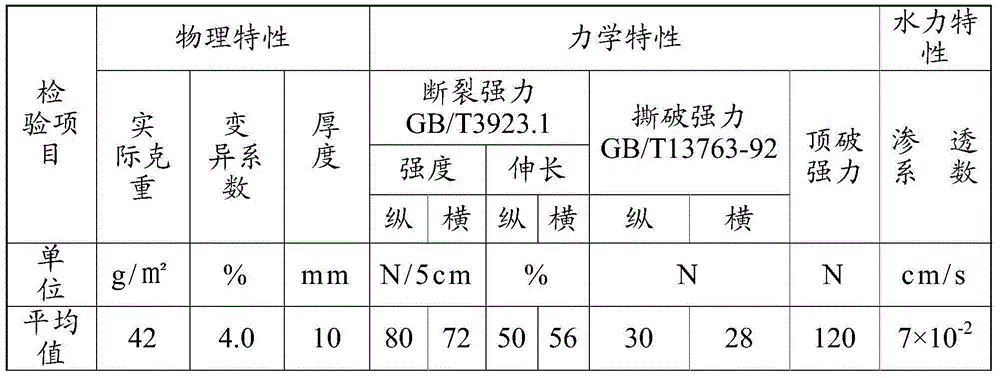

Embodiment 1

[0035] After the PET chips with an intrinsic viscosity of 0.8 are screened by a vibrating sieve, they enter a fluidized bed for crystallization at 140°C, and then enter a packed drying tower for drying at a drying temperature of 170°C. After drying, the moisture content of the PET chips is less than 30ppm;

[0036] Melt and mix the dried PEI slices in the extruder, and control the temperature in zone 1-7 of the extruder at 275±2°C, 285±2°C, 290±2°C, 295±2°C, 315±2°C, 310±2°C, 310±2°C to obtain a melt;

[0037] The melt is filtered in a filter with a temperature of 310±2°C, and the pre-filter pressure is 65MPa; then it enters a spinning box at 320±5°C for spinning, with a spinning pressure of 65MPa and a pore size of 0.8 The spinneret holes of mm form as-spun filaments, and then enter the drafter to draw at a speed of 5600m / min after cooling under the cooling air of 20±1°C to form PET fibers;

[0038] The PET fiber is passed through a spinning device and a web forming machine ...

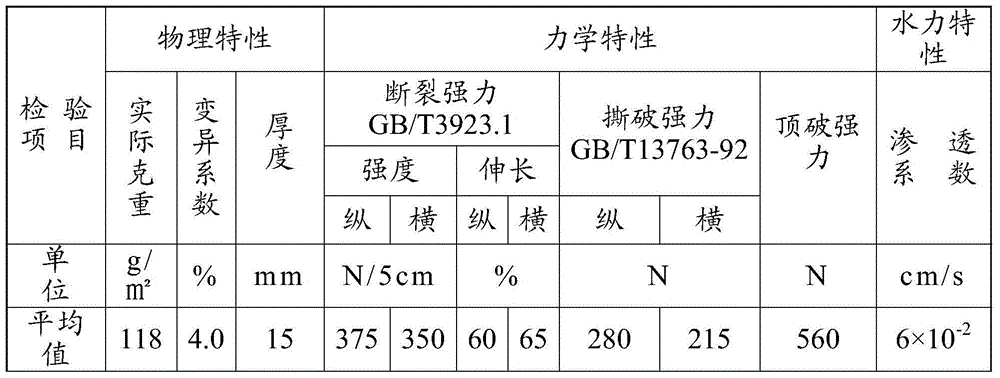

Embodiment 2

[0043] PET slices with an intrinsic viscosity of 1.0 are screened by a vibrating sieve, then enter a fluidized bed for crystallization at 145°C, and then enter a packed drying tower for drying at a drying temperature of 175°C. After drying, the moisture content of the PET slices is less than 30ppm;

[0044] Melt and mix the dried PEI slices in the extruder, and control the temperature in zone 1-7 of the extruder at 275±2°C, 285±2°C, 290±2°C, 295±2°C, 315±2°C, 310±2°C, 310±2°C to obtain a melt;

[0045] The melt is filtered in a filter with a temperature of 310±2°C, and the pre-filter pressure is 65MPa; then it enters a spinning box at 320±5°C for spinning, with a spinning pressure of 65MPa and a pore size of 0.8 The spinneret holes of mm form as-spun filaments, and then enter the drafter to draw at a speed of 5600m / min after cooling under the cooling air of 20±1°C to form PET fibers;

[0046] The PET fiber is passed through a spinning device and a web forming machine to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com