Refining processing method of fibrilia

A processing method and technology of hemp fiber, applied in the direction of chemical post-treatment of fiber, fiber treatment, bast fiber produced by chemical method, etc., can solve poor application performance, unsatisfactory flexibility and spinnability of jute kenaf fiber To improve the smoothness of the surface, loose the overall structure of the fiber, and improve the effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

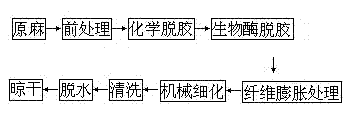

Image

Examples

Embodiment 1

[0020] Step 1: After the raw hemp is subjected to a water bath or an acid bath, a sodium hydroxide solution is used for chemical degumming treatment.

[0021] Step 2: using pectinase or laccase to carry out biological enzyme degumming.

[0022] Step 3: Carry out fiber expansion treatment to the fiber by using a composite expansion aid, wherein the composite expansion aid is composed of a penetrating agent, an expanding agent, and an auxiliary agent for dissolving colloidal components in the fiber, and its mass ratio is 1:1:1; The additives for the colloidal component in the fiber include concentrated sulfuric acid, sodium hydroxide and biological enzymes with a concentration of 85%. When the composite expansion aid is treated, the composite expansion aid must be diluted into an aqueous solution with 10 times of water, and then the water ratio The ratio is 1:20, the temperature is 50°C, and the time is 0.5 hours to process the hemp fiber.

[0023] Step 4: Mechanical thinning t...

Embodiment 2

[0029] Step 1: After the raw hemp is subjected to a water bath or an acid bath, a sodium hydroxide solution is used for chemical degumming treatment.

[0030] Step 2: using pectinase or laccase to carry out biological enzyme degumming.

[0031] Step 3: Carry out fiber expansion treatment to the fiber by using a composite expansion aid, wherein the composite expansion aid is composed of a penetrating agent, an expanding agent, and an auxiliary agent for dissolving colloidal components in the fiber, and its mass ratio is 1:1:1; The additives for the colloidal component in the fiber include concentrated sulfuric acid, sodium hydroxide and biological enzymes with a concentration of 90%. When the composite expansion aid is treated, the composite expansion aid must be diluted into an aqueous solution with 10 times of water, and then the water ratio The ratio is 1:25, the temperature is 55°C, and the time is 2 hours to process the hemp fiber.

[0032] Step 4: Mechanical thinning tre...

Embodiment 3

[0038] Step 1: After the raw hemp is subjected to a water bath or an acid bath, a sodium hydroxide solution is used for chemical degumming treatment.

[0039] Step 2: using pectinase or laccase to carry out biological enzyme degumming.

[0040] Step 3: Carry out fiber expansion treatment to the fiber by using a composite expansion aid, wherein the composite expansion aid is composed of a penetrating agent, an expanding agent, and an auxiliary agent for dissolving colloidal components in the fiber, and its mass ratio is 1:1:1; The additives for the colloidal component in the fiber include concentrated sulfuric acid, sodium hydroxide and biological enzymes with a concentration of 95%. When the composite expansion aid is treated, the composite expansion aid must be diluted into an aqueous solution with 10 times of water, and then the water ratio The temperature is 1:30, the temperature is 60°C, and the time is 4 hours to process the hemp fiber.

[0041] Step 4: Mechanical thinni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com