Method applied to evaluation of flow conductivity of shale-gas-combined sand fracturing fracture

A technology for sand fracturing and flow conductivity, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., to achieve the effect of practical and accurate quantitative evaluation of the test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] As a preferred embodiment of the present invention, see figure 1 , figure 2 , image 3 .

[0071] Test required proppant quality:

[0072] in :W p1 --- 40 / 70 mesh ceramsite quality;

[0073] W p2 --- 100 mesh quartz sand quality;

[0074] W p3 --- 20 / 40 mesh ceramsite quality;

[0075] A method for evaluating the conductivity of shale gas combined sand fracturing fractures, comprising the following steps in sequence:

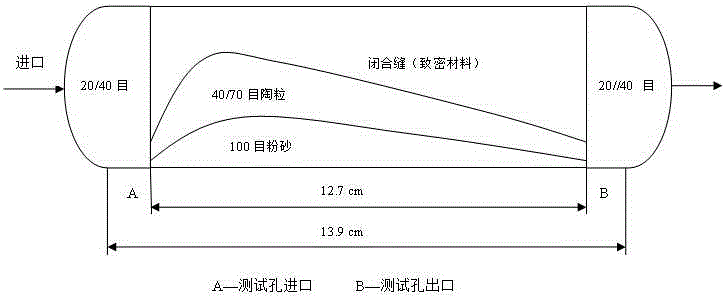

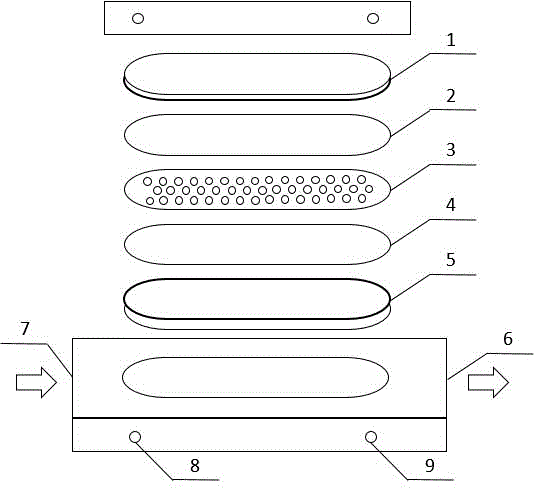

[0076] (1) According to the obtained distribution shape function F of proppant with different particle sizes in the API diversion chamber 1 (x, t), F 2 (x, t), draw the boundary line of different proppants on a metal plate 5;

[0077] (2) The paving area A of different proppants (100 mesh quartz sand, 40 / 70 mesh ceramsite and 20 / 40 mesh ceramsite) was obtained by geometric integral 1 , A 2 , A 3 , and then get the mass W of the corresponding proppant according to the laying thickness H and proppant density p1 , W p2 , W p3 ;

[00...

Embodiment 2

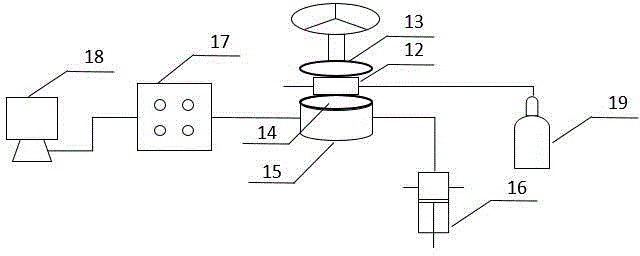

[0091] As the best implementation mode of the present invention, the present invention mainly includes: description and recording of the distribution shape of sand banks in visual fractures in combined sand fracturing, establishment of distribution shape functions of different proppant sand banks, and experimental measurement and evaluation of conductivity in fractures Wait for three parts. The specific steps are:

[0092] a. With the help of the simulation experiment device for proppant flow in the visualized fracture network, simulate the migration process of the sand embankment in the shale gas slick water combined sand fracturing fracture, and obtain the sand embankment migration video of the combined sand fracturing under different experimental conditions;

[0093] b. Using the grayscale processing method and the point-by-point scanning method to obtain the distribution curves of proppant sand banks with different particle sizes, and use the linear regression method to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com