Variable displacement triple plunger super-pressure pump

A variable, ultra-high pressure technology, applied in the direction of pump control, liquid displacement machinery, machine/engine, etc., can solve the problem that the three-plunger ultra-high pressure pump cannot be variable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

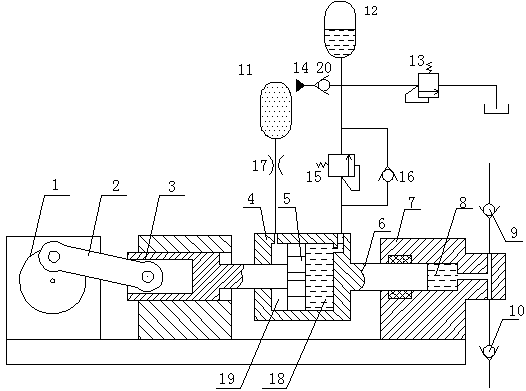

[0015] see figure 1 As shown, the variable displacement three-plunger ultra-high pressure pump consists of a crankshaft (1), a connecting rod (2), a slider (3), a variable displacement oil cylinder (4), and a high pressure cylinder (7). The piston (5) of the variable cylinder (4) is connected with the slide block (3) through the piston rod, and the plunger (6) connected with the variable cylinder (4) extends into the plunger hole of the high pressure cylinder (7) and connects with the high pressure The cylinder forms a closed volume (8), and cooperates with the check valves (9) and (10) to form a variable displacement pump.

[0016] In the initial state, the air bag (11) is filled with compressed gas, and the pressure oil from the hydraulic source (14) fills the hydraulic accumulator (12) through the one-way valve (20), and at the same time enters the variable oil cylinder through the one-way valve (16). (4) Rodless chamber (18), since the hydraulic oil pressure and effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com