Sealed structure for gas aided injection molding technological hole of automobile door handle

A gas-assisted injection molding and sealing structure technology, which is applied to the sealing of the engine, the handle of the wing fan, the ball handle of the wing fan, etc., can solve the problems of poor sealing effect, pollution of the electroplating pool, cross-contamination, etc., to achieve convenient operation and reduce Loss, the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

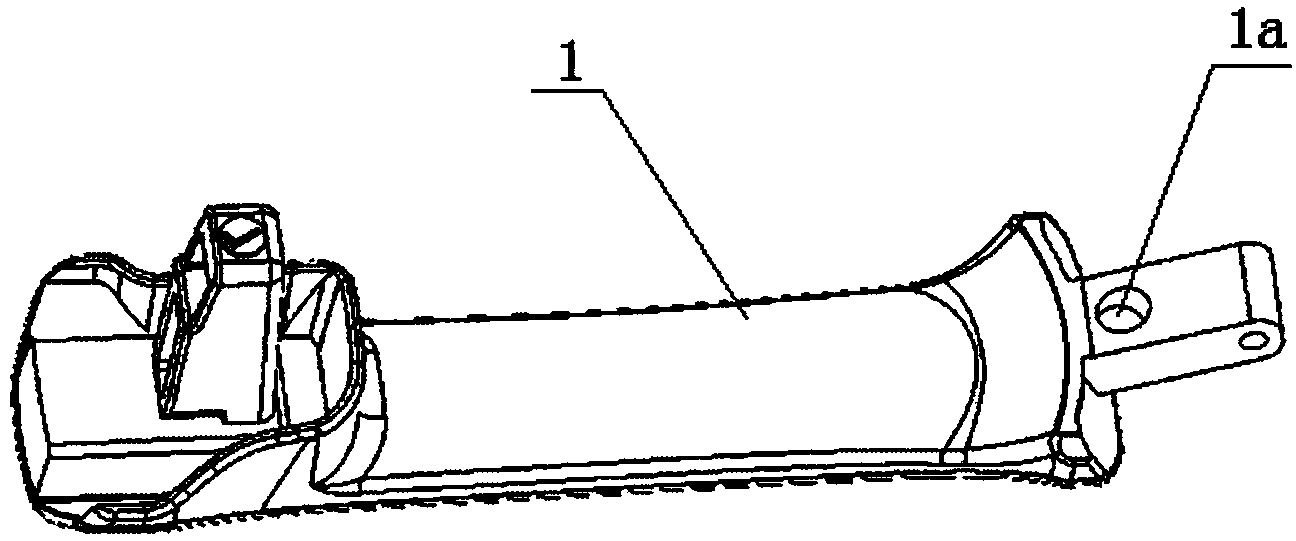

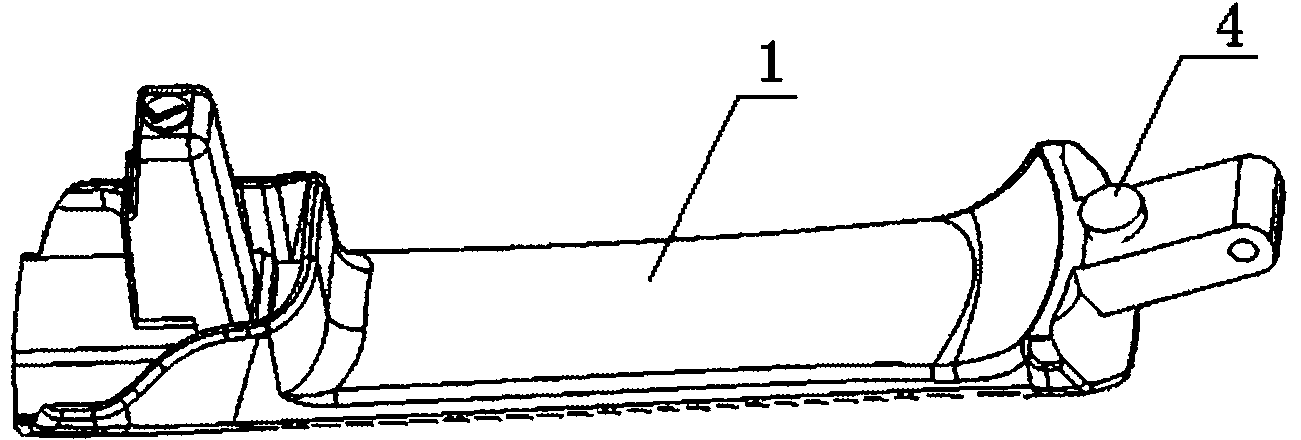

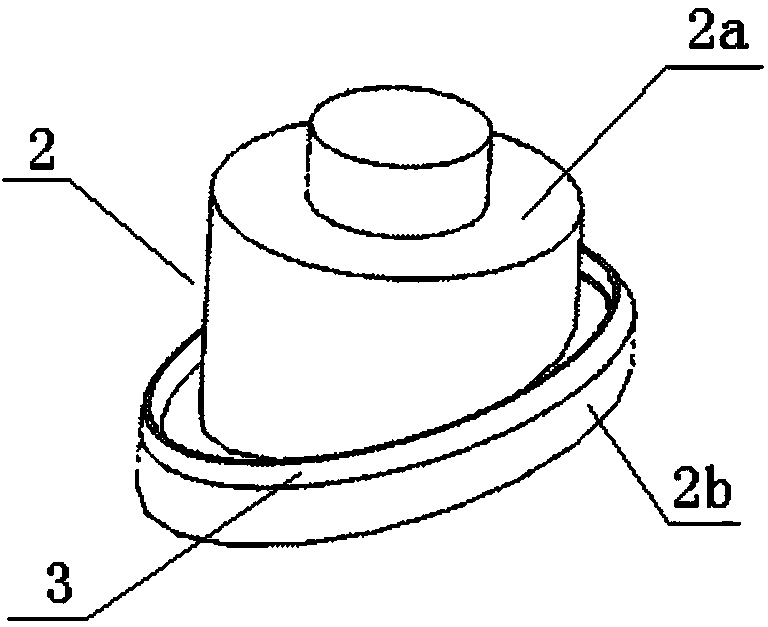

[0013] Such as figure 1 , image 3 As shown, the sealing structure of the gas-assisted injection molding process hole on the automobile door handle in the embodiment is mainly composed of a door handle 1 and a plugging cover 2, the door handle 1 is formed by a gas-assisted injection molding process hole 1a, and the plugging cover 2 is used It is used to block the gas-assisted injection molding process hole 1a; the plugging cover 2 includes a main body portion 2a and a cap portion 2b integrally arranged, the main body portion 2a is used to be inserted into the gas-assisted injection molding process hole 1a, and the cap portion 2b The outer diameter is larger than the hole diameter of the gas-assisted injection molding process hole 1a, and the lower surface of the cap part 2b is provided with a circle of plugging 2 welding wires 3 that can be melted under ultras...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap