Binocular vision measuring system having variable structure and parameter determining method

A binocular vision measurement and parameter determination technology, applied in the field of vision measurement, can solve the problems of inability to solve the real-time calibration of the external parameters of the binocular camera, limit the application and promotion of variable structure binocular vision, and the small application range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

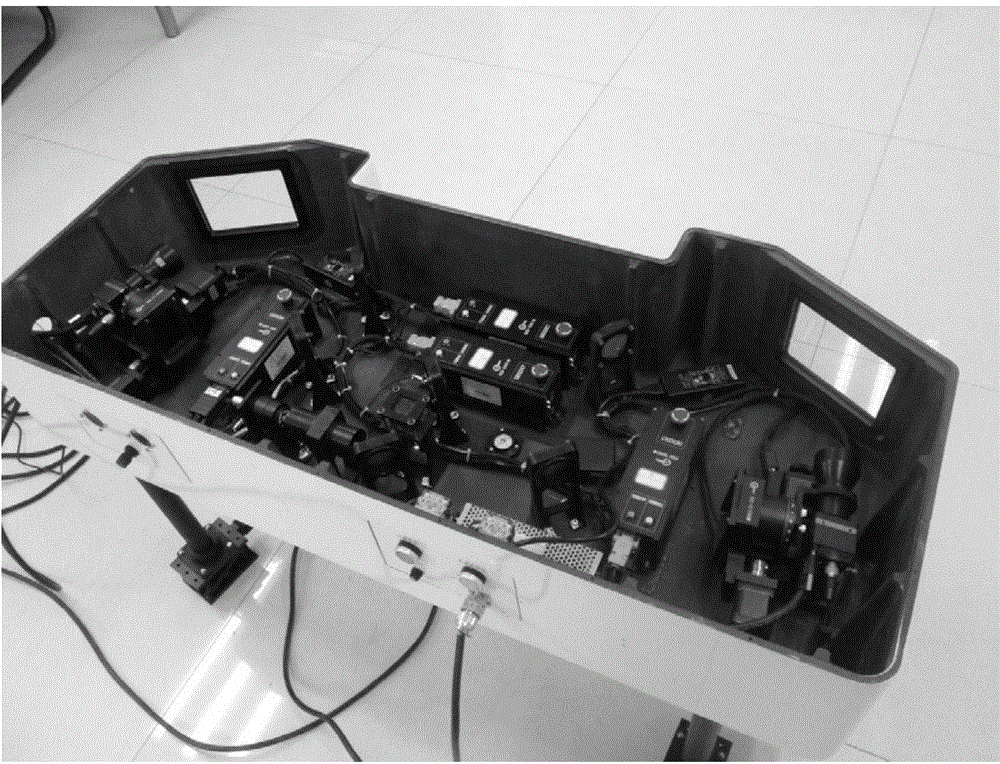

[0056] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

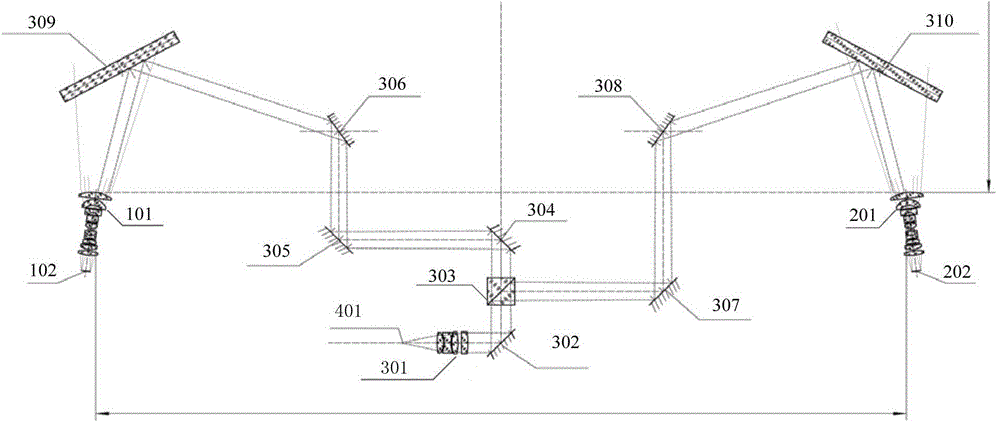

[0057] The invention comprises two left and right optical paths, two photographic objective lenses with consistent optical parameters are located in the two optical paths respectively, the focal length of the photographic objective lens is 30 mm, and a built-in collimator is used to provide a reference mark, in the imaging field of view through a certain The optical path is imaged in the system, providing a reference mark at infinity for the photographic objective lens.

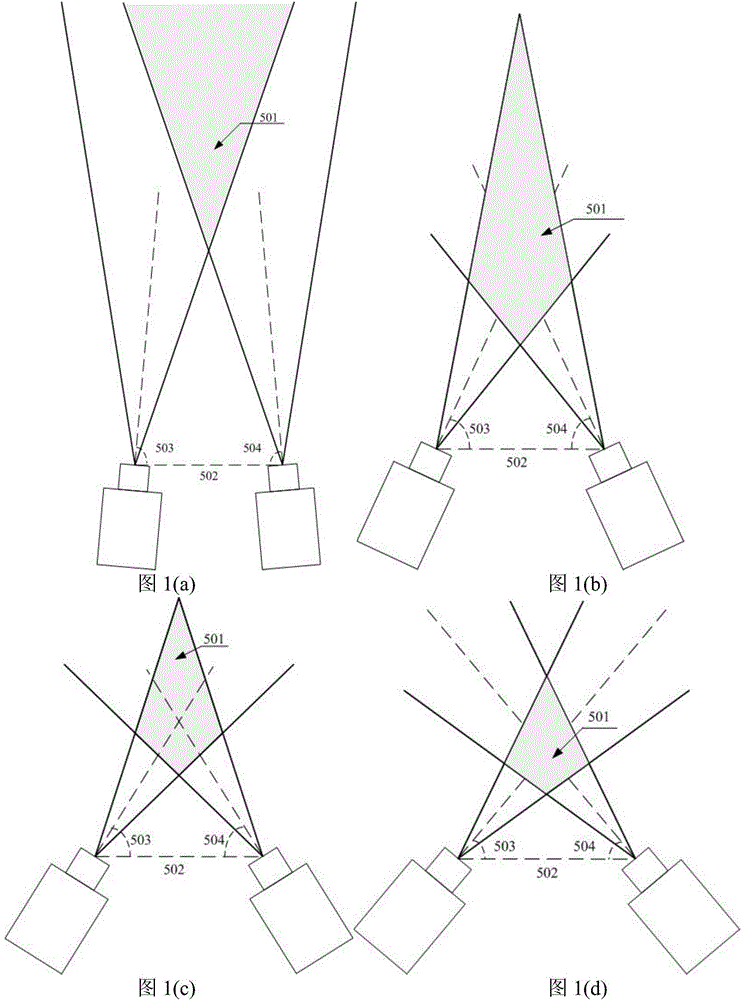

[0058] The specific structure is composed of figure 2 , 3 As shown, the present invention includes: the main optical path 1 of the left camera, the main optical path 2 of the right camera, the auxiliary optical path 3 and the reference mark 401. The reference mark is a plane calibration reference object; wherein, the main optical path 1 of the left camera includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com