Device and method for ultrasonic testing of engine fuel oil header pipe soldered joints

A technology for fuel manifolds and brazing joints, which is applied to measurement devices, uses ultrasonic/sonic/infrasonic waves, and uses sonic/ultrasonic/infrasonic waves to analyze solids, etc. Blurred black lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

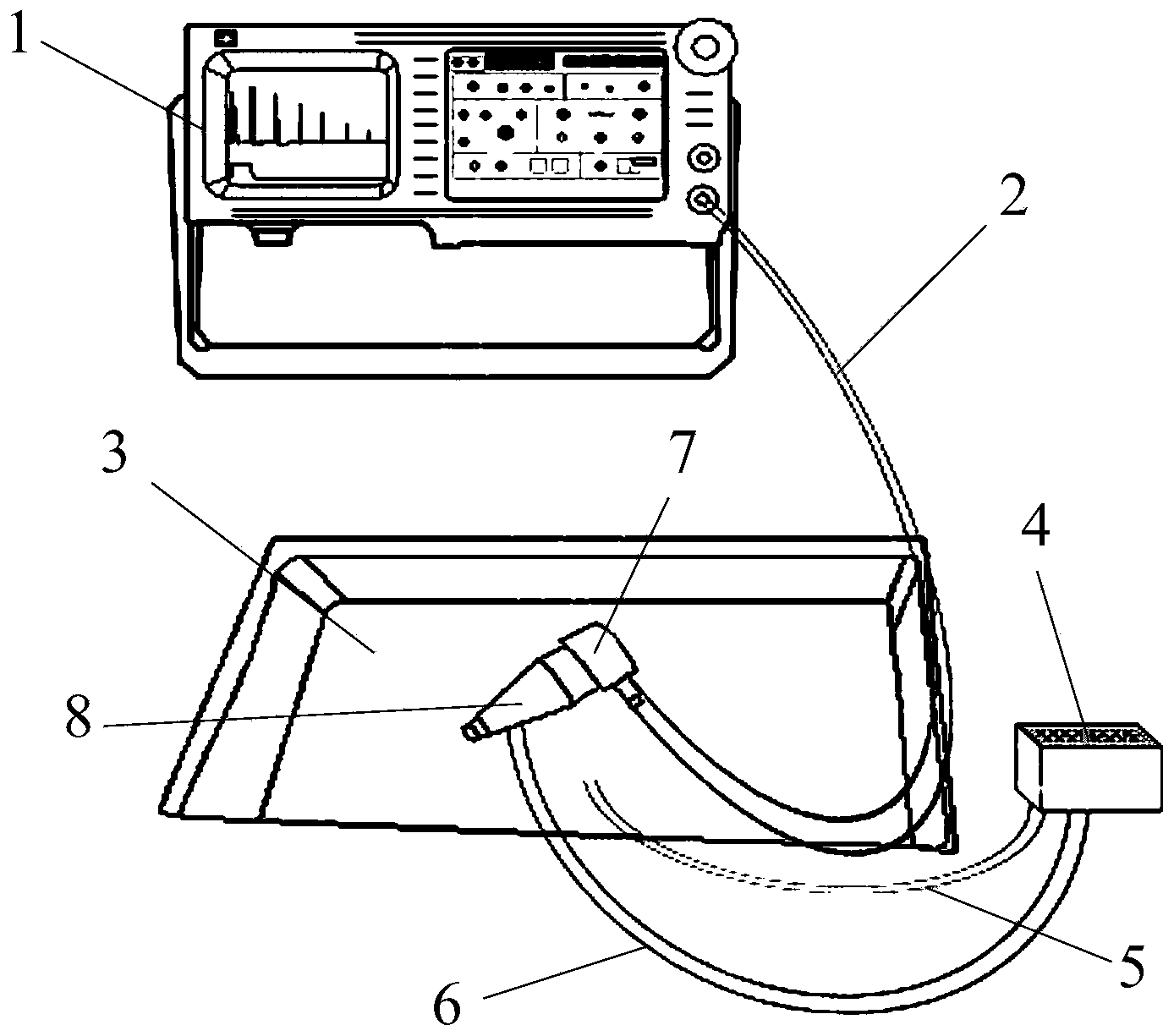

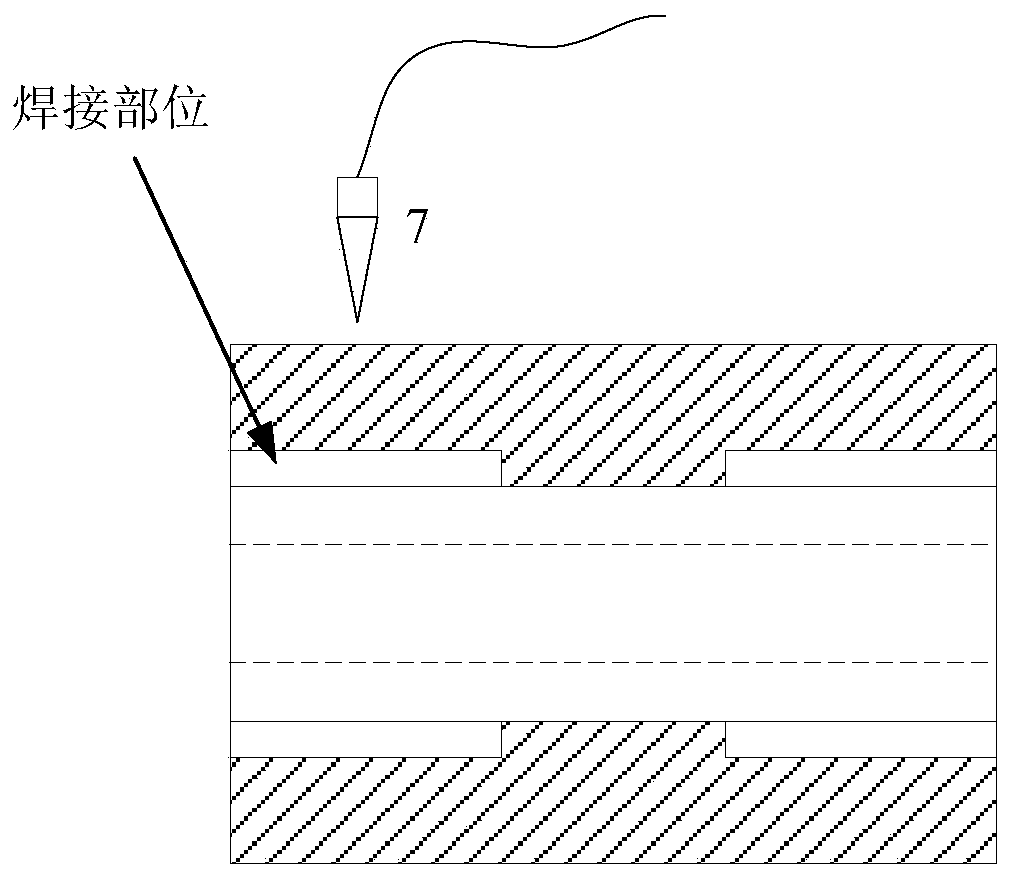

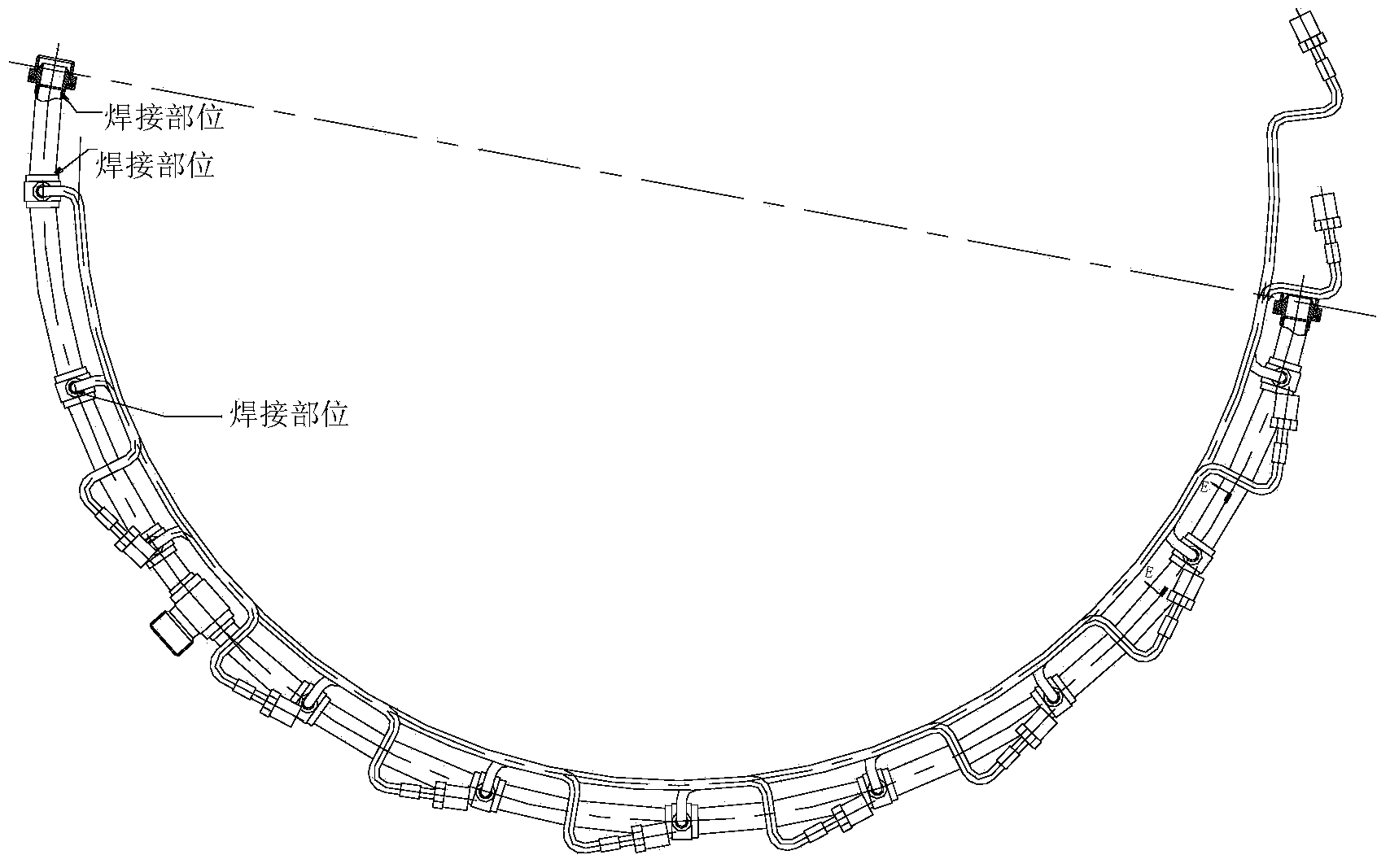

[0033] see figure 1 , the present invention is a method for detecting the welding quality of a certain engine fuel manifold brazing position by using the above-mentioned ultrasonic detection method. According to the parts to be inspected, the above-mentioned method is used to perform ultrasonic wall thickness detection for example. The specific invention includes the following steps:

[0034] 1) Connect the ultrasonic detector 1, the probe 7 and the water spray device; the ultrasonic detector 1 adopts a high-frequency, high-resolution ultrasonic detector model NOVASCOPE 5000. Probe 7 is a point-focused probe with a model number of E11877 and a frequency of 25 MHz. The probe 7 is connected to the ultrasonic detector 1 through the coaxial cable connection 2; the water spray device includes a water pump 4 and a conical water jacket 8 set on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com