Preparation method of nickel hydride battery and nickel hydride battery product

A nickel-metal hydride battery and battery technology, which is applied in the field of nickel-metal hydride battery preparation and nickel-metal hydride battery products, can solve the problems of low bonding fastness of the inner surface of the metal shell, zero electricity of the battery, and high battery scrap rate, so as to save sealing. Commissioning time and manpower, preventing the hidden danger of explosion, reducing the effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

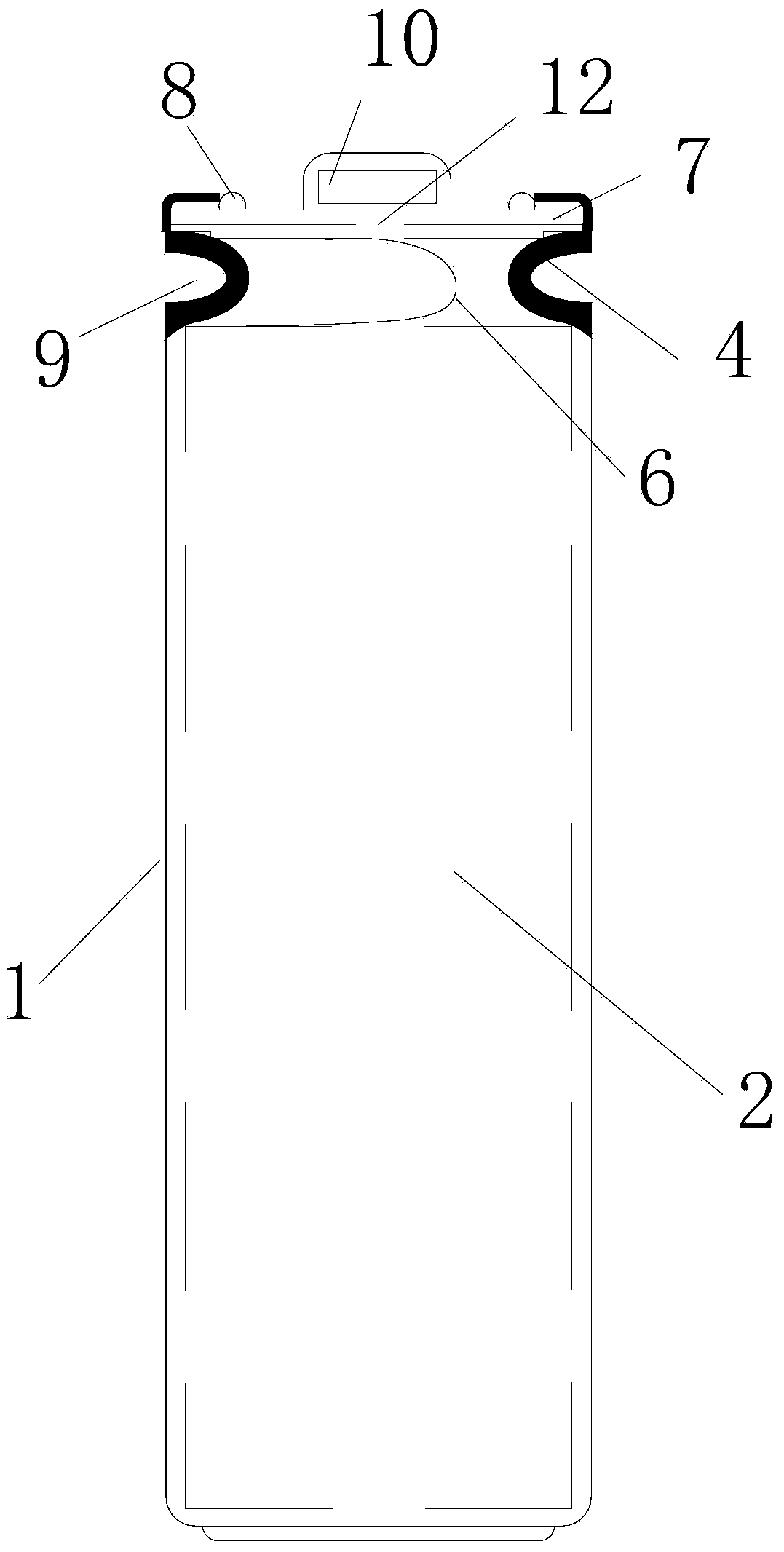

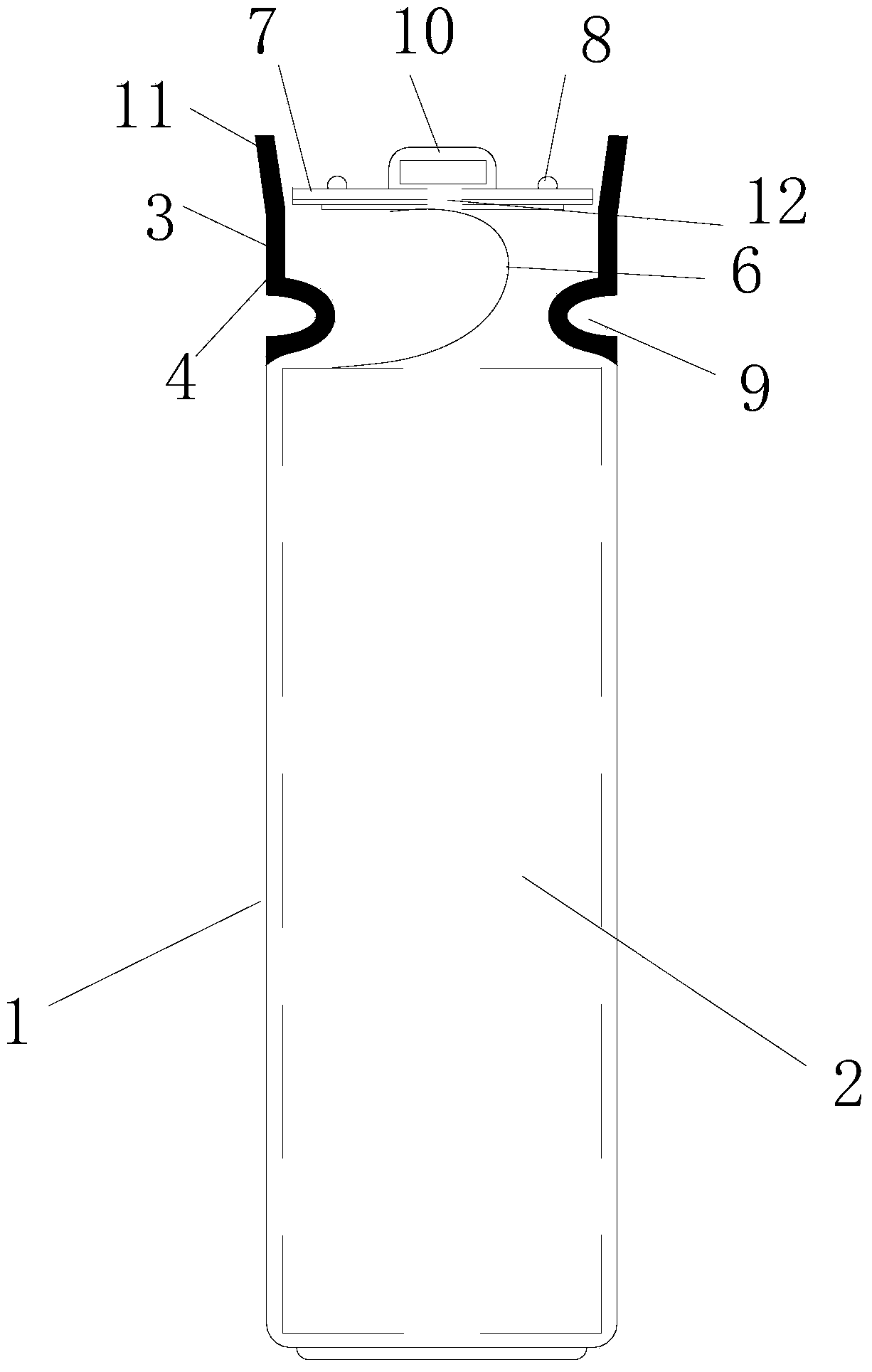

[0029] Example: see Figure 1 to Figure 3 , the preparation method of the nickel-metal hydride battery provided by the present embodiment, it comprises the following steps:

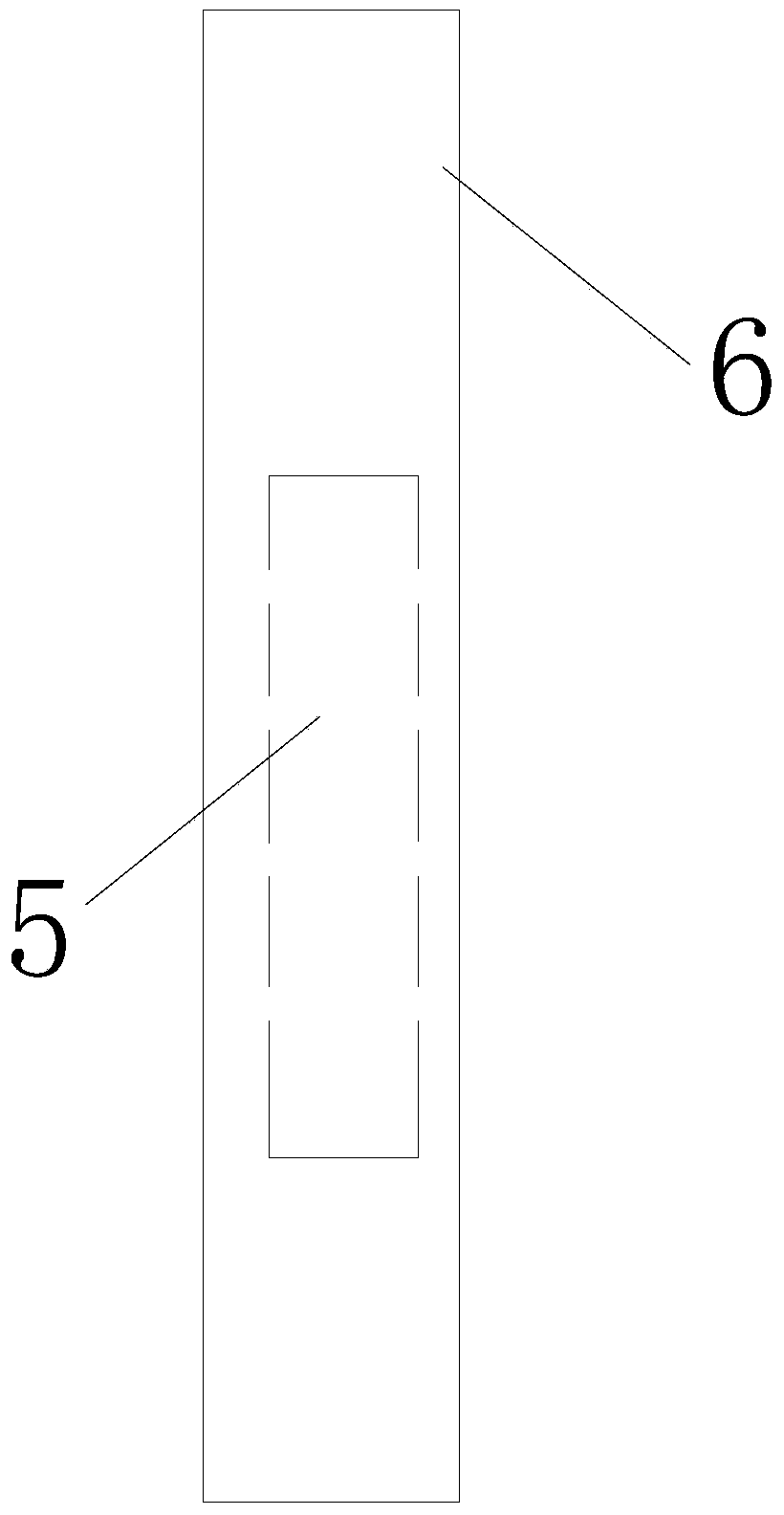

[0030] (1) Prepare a cylinder casing 1 with an upper end opening 3, and an electric core 2 that can be put into the casing 1; an outwardly extending guide wide mouth 11 is set at the end of the opening, and the guide wide mouth 11 The outward extension angle is 15-30 degrees, and the opening and the guide wide mouth 11 are integrally formed, and a curved surface is provided between the guide wide mouth 11 and the opening. Guide the wide mouth 11 and the curved surface, slide into the inside of the shell 1, and reduce the scrap rate;

[0031] (2) On the inner wall of the cylinder shell 1 opening 3 places, an insulating coating 4 is coated; the insulating coating 4 is now a wet film layer coated with a specially prepared modified epoxy resin;

[0032] (3) Pack the electric core 2 prepared in step (1) into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com