Preparation method of lithium-rich layered positive electrode material coated with lithium silicate for lithium ion battery

A technology for ion batteries and positive electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., to achieve the effects of easy control of reaction conditions, simple synthesis process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of the lithium-silicate-coated lithium-ion battery lithium-rich layered cathode material proposed by the present invention comprises the following steps:

[0016] (1) Preparation of oxalate precursor:

[0017] According to the molar ratio NiSO 4 , MnSO 4 Dissolve in 50ml of water so that the molar concentration of metal Ni ions and metal Mn ions is both 2mol / L to obtain a mixed solution of metal ions, and then configure NaC with a molar concentration of 2mol / L 2 o 4 Solution 50mL, under magnetic stirring, NaC 2 o 4 The solution was added to the mixed solution of metal ions to produce a precipitate. After stirring for 2 hours, it was centrifuged, and the precipitate was washed twice with deionized water and absolute ethanol respectively. The precipitate was dried in an oven at 70°C for 12 hours to obtain the Salt precursor, the molecular formula of oxalate precursor is: Ni0.35Mn0.65C 2 o 4 2H 2 O;

[0018] (2) SiO 2 Preparation of coated ...

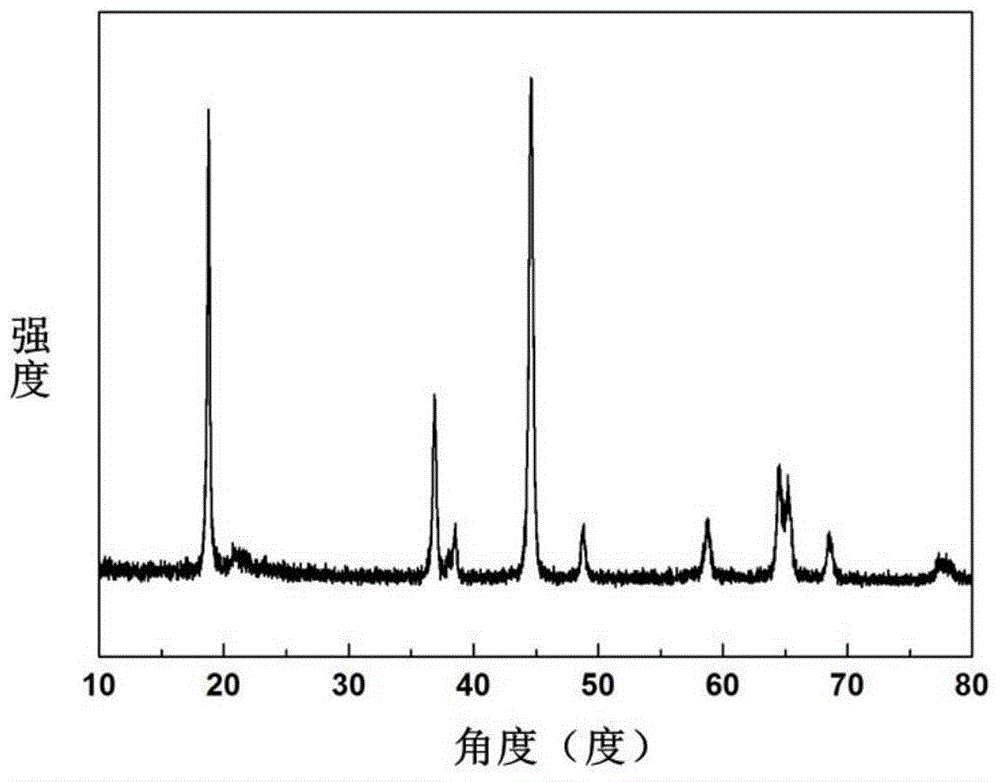

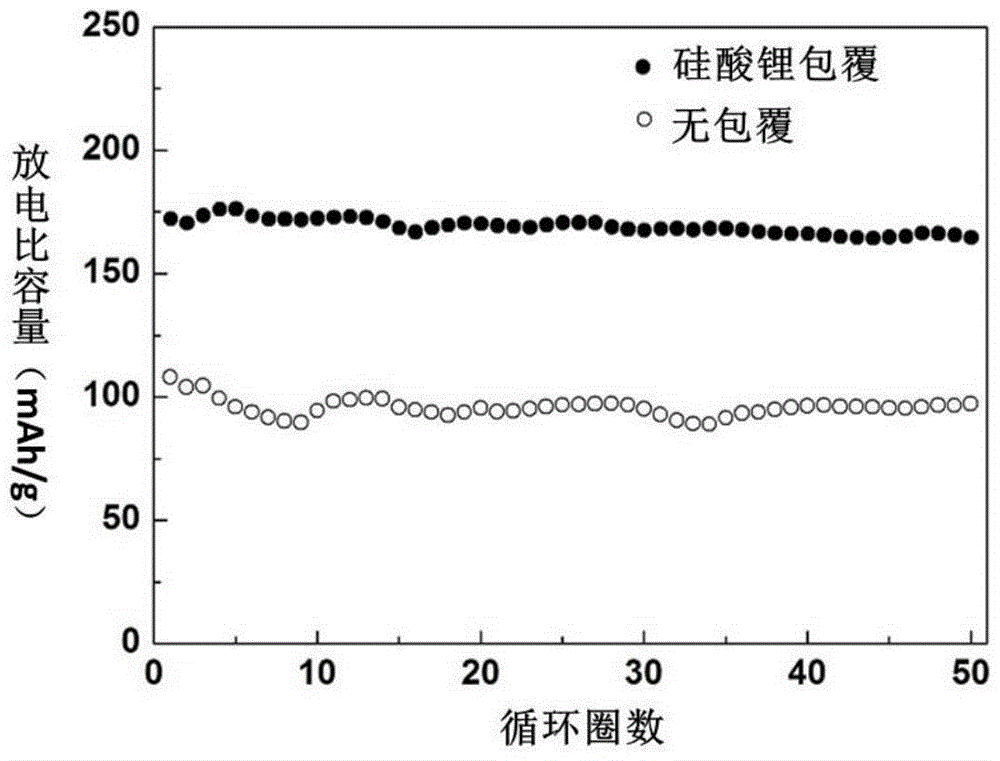

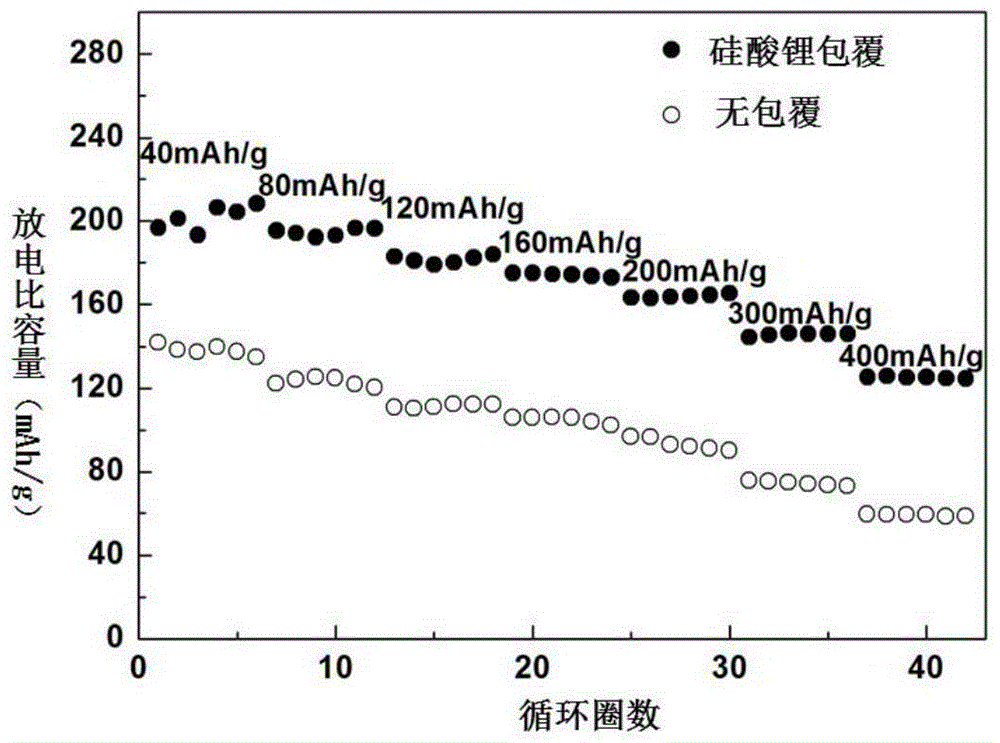

Embodiment 1

[0024] (1) Preparation of oxalate precursor: mix NiSO 4 , MnSO 4 Dissolve in 50ml of water so that the molar concentration of metal Ni ions and metal Mn ions are both 2mol / L, and then configure 2mol / L NaC 2 o 4 Solution 50mL, under magnetic stirring, NaC 2 o 4 The solution was added to the mixed solution of metal ions, and a large amount of precipitation was produced immediately. After stirring for 2 hours, centrifuged, washed twice with deionized water and absolute ethanol, and dried in a 70-degree oven for 12 hours, the oxalate precursor was obtained. body;

[0025] (2) SiO 2 Synthesis of coated oxalate precursor: Weigh 1.2 mmol of the above-obtained oxalate precursor and disperse it in 13 ml of absolute ethanol, stir and ultrasonically disperse. According to the molar ratio of Si:(Ni+Mn)=3:100, Si(OC 2 h 5 ) 4 Anhydrous ethanol solution, stir to disperse evenly. Then the mixed solution was transferred to a thoroughly dry polytetrafluoroethylene-lined hydrothermal ...

Embodiment 2

[0029] (1) Preparation of oxalate precursor: a certain amount of NiSO 4 , MnSO 4 Dissolve in 50ml of water so that the molar concentration of metal Ni ions and metal Mn ions are both 2mol / L, and then configure 2mol / L NaC 2 o 4 Solution 50mL, under magnetic stirring, NaC 2 o 4 The solution was added to the mixed solution of metal ions, and a large amount of precipitation was produced immediately. After stirring for 2 hours, centrifuged, washed twice with deionized water and absolute ethanol, and dried in a 70-degree oven for 12 hours, the oxalate precursor was obtained. body;

[0030] (2) SiO 2 Synthesis of coated oxalate precursor: Weigh 1.2 mmol of the above-obtained oxalate precursor and disperse it in 13 ml of absolute ethanol, stir and ultrasonically disperse. According to the molar ratio of Si:(Ni+Mn)=3:100, Si(OC 2 h 5 ) 4 Anhydrous ethanol solution, stir to disperse evenly. Then the mixed solution was transferred to a thoroughly dry polytetrafluoroethylene-lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com