High-voltage line deicing robot

A high-voltage transmission line and robot technology, applied in overhead lines/cable equipment, cable installation, overhead installation, etc., can solve the problems of manpower and material resources, low deicing efficiency, high risk of manual deicing, and ensure accurate Effects of Sexuality and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific content and working process of the high-voltage transmission line deicing robot of the patent of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

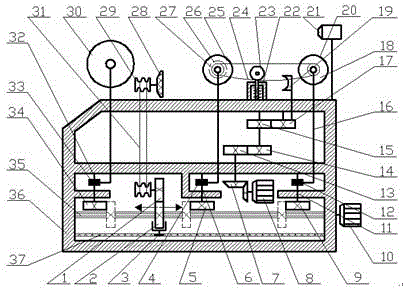

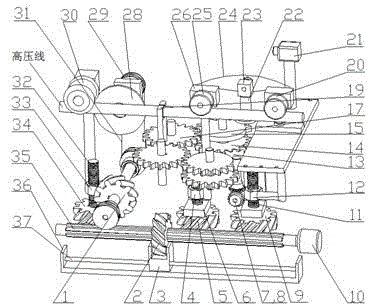

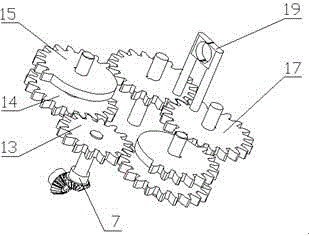

[0019] Figure 1 is a schematic diagram of the overall structure of a high-voltage line deicing robot, which is mainly composed of a frame, a transmission system, a deicing tool, an obstacle overcoming mechanism, a walking mechanism, and a camera unit. In the transmission system, the bevel gear (7) transmits the power of the motor (8) to the reduction gear (13) coaxially connected with the bevel gear (7), and the reduction gear meshes with the spur gear (14). The two-stage gear transmission transmits power to the gear (17), and the gear (17) drives the deicing hammer fixedly connected with it to move. The deicing tool mainly uses a pair of deicing grinding wheels and a set of deicing hammers to remove the icing on the high voltage line. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com