Solar cell frame

A solar cell and frame technology, applied in photovoltaic power generation, electrical components, photovoltaic modules, etc., can solve the problems of reducing the strength of the plug-in, chipping or falling off, low stability of the solar cell frame, etc., to enhance the connection strength, easy installation and Precise, robust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

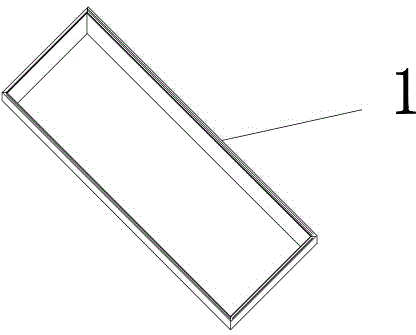

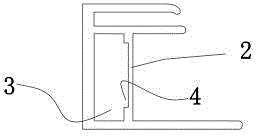

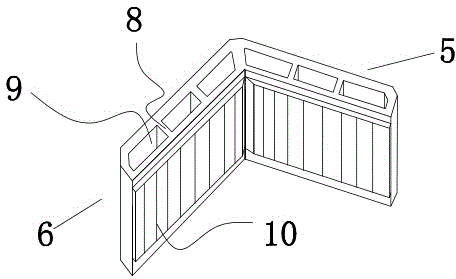

[0017] The solar cell frame of this embodiment, such as Figure 1 to Figure 5 As shown, four U-shaped plates 1 including corner keys and end-to-end connection, adjacent U-shaped plates 1 are fixedly connected by corner keys; And the second plug board 6, the first plug board 5 and the second plug board 6 are affixed and make the cross section of the corner key body L-shaped; the first plug board 5 and the second plug board 6 All are hollow structures 9, and a plurality of reinforcing ribs 8 are evenly arranged at intervals in the hollow structures 9; sliders 11 are formed on the opposite surfaces of the first plug board 5 and the second plug board 6, and slide blocks 11 are formed on the first plug board 5 And the other side of the second socket board 6 is provided with serrated barbs 7 .

[0018] The opening of the U-shaped plate 1 is provided with a support plate 2, and a cavity 3 is formed between the support plate 2 and the U-shaped plate 1. The support plate 2 is formed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com