Personalized metallic dental pile simulating mechanical property of natural tooth and manufacturing method thereof

A manufacturing method and technology of dental posts, which are applied in the fields of implantology, dentistry, medical science, etc., can solve problems such as insufficient root bonding, high elastic modulus, and easy fracture, so as to improve the long-term retention rate and facilitate Retention and storage, improving the effect of inconsistent stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

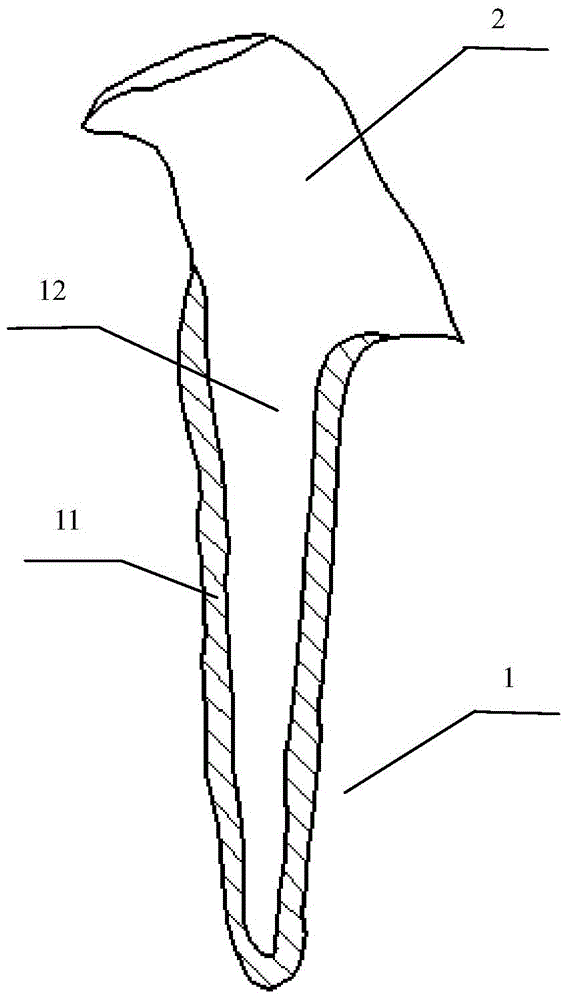

[0045] Such as picture 1 shows a personalized metal dental post simulating the mechanical properties of natural teeth. It consists of a post 1 and a core 2. The post 1 and the core 2 are integrally formed. The post 1 is composed of a dense part 12 and a loose part 11. The dense part 12 is wrapped in Inside the loose part 11; the loose part is composed of a material whose elastic modulus is lower than that of the dense part. For example, the dense part is composed of metal materials with high elastic modulus such as cobalt chromium alloy and titanium alloy, or non-metallic materials with high elastic modulus such as ceramics; the loose part is composed of gold alloy, silver amalgam and other low elastic materials. Modulus metallic materials, or non-metallic materials with lower elastic modulus such as fiber reinforced resins.

[0046] The advantage of this embodiment is:

[0047] 1. Set the loose part on the pile, adjust the elastic modulus of the loose part by selecting the ...

Embodiment 2

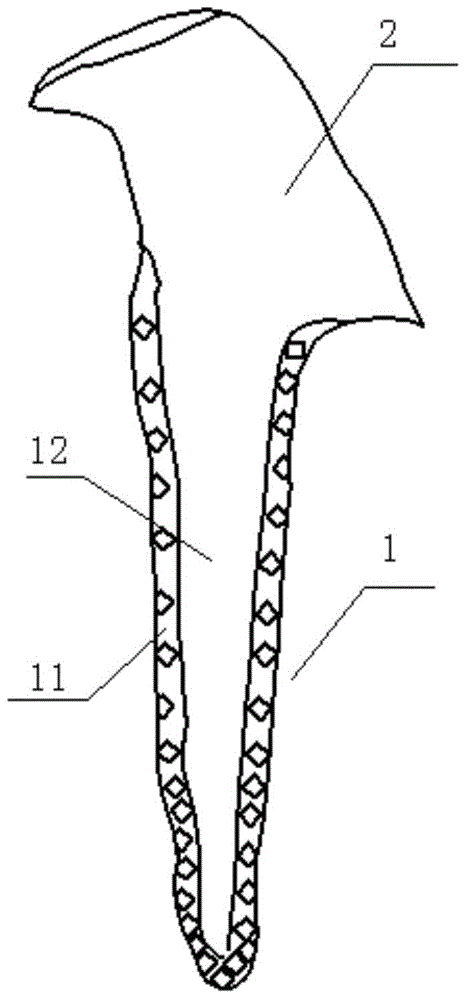

[0051] Such as picture 2 shows a personalized dental post, which is composed of a post 1 and a core 2. The post 1 and the core 2 are integrally formed. The post 1 is composed of a dense part 12 and a loose part 11. The porosity of the loose part 11 is the same as that of the loose part 11. The relationship between the modulus of elasticity is: ,in, is the modulus of elasticity of the loose part 11, C , k is a constant, is the modulus of elasticity of the dense part 12, is the porosity of the loose part.

[0052] The pores of the porous structure are distributed irregularly, as long as the porosity can make the equivalent elastic modulus of the loose part reach the preset elastic modulus.

[0053] The advantage of this embodiment is:

[0054] 1. Set the loose part on the pile, and adjust the porosity of the loose part to make the elastic modulus of the loose part lower than that of the dense part, thereby reducing the risk of damage to the dentin due to the high hard...

Embodiment 3

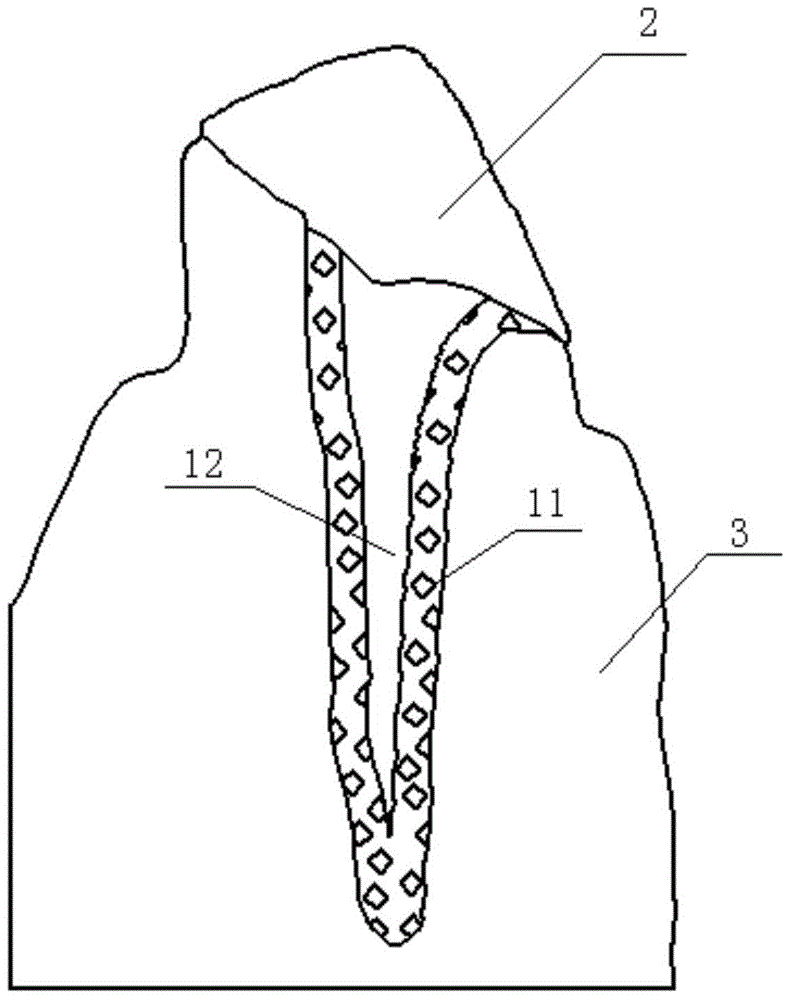

[0057] The difference between this embodiment and embodiment 2 is: as picture The pores of the porous structure shown in 3 are regularly distributed. Specifically: the porous structure is composed of multiple pore units, each pore unit is composed of a shell A and a pore B, and the pore B is in the shell A as picture 111A as shown in 4, or shell A in hole B as picture In 111B shown in 4, the pore units are evenly and regularly distributed, and the pore units are closely attached to each other. The porosity of the porous structure is adjusted to realize the individual adjustment of the equivalent elastic modulus of the dental post. The porous structure and the dense part use the same material make.

[0058] Such as picture As shown in 5 and 6, the so-called shell in the hole means that the hole unit 111B needs to cooperate with other hole units 111B to form an empty area, and the enclosed empty area is called hole B, which cooperates with other hole units Part becomes Shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com