A Radial Constant Temperature Reactor with Water Transfer Heat

A reactor and heat removal technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of large system resistance, low recovery efficiency of sensible heat and latent heat, large investment in equipment, etc., to solve the problem of easy overheating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

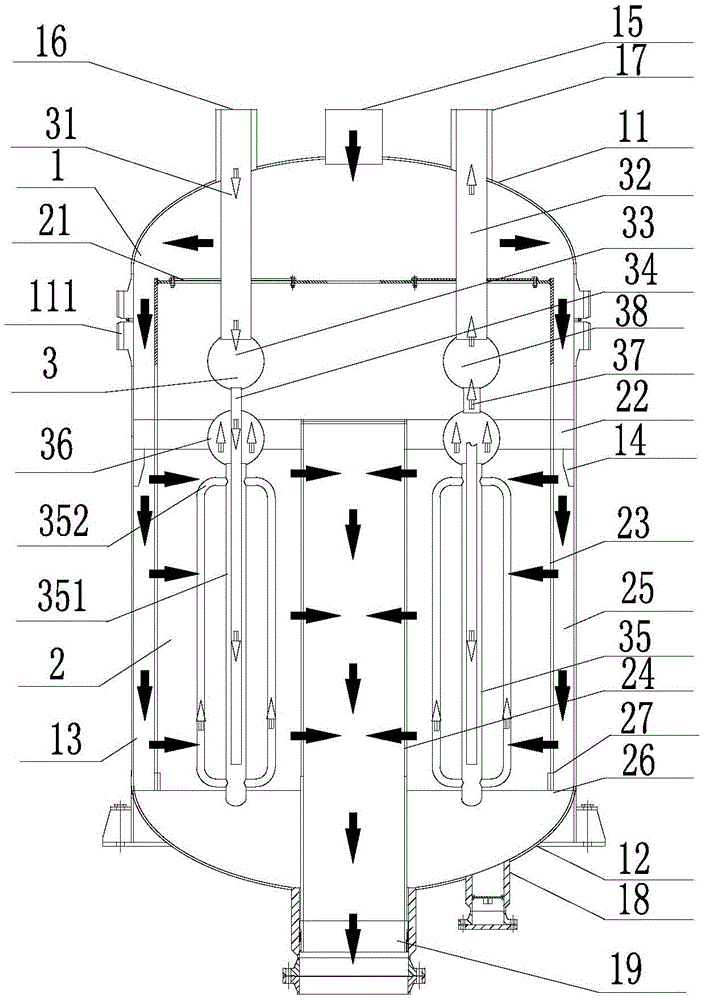

Image

Examples

Embodiment 2

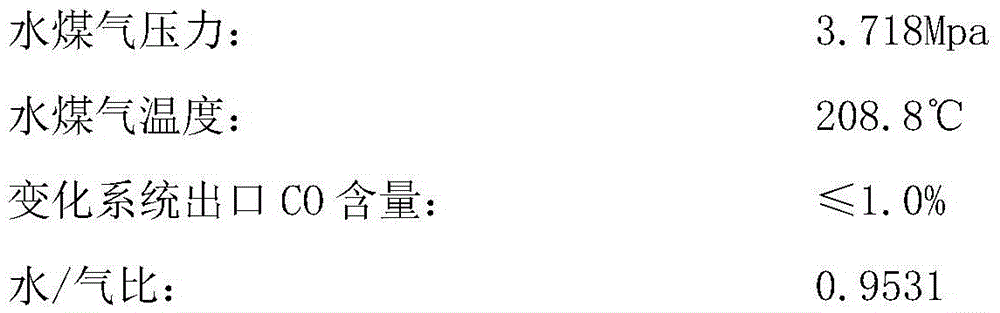

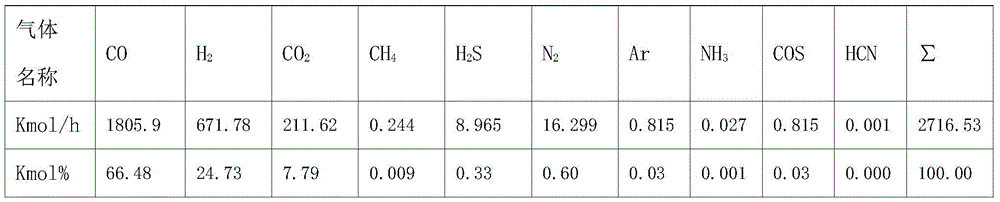

[0040] This embodiment is applied to a 400,000-ton / year synthetic ammonia plant with a low water / gas ratio, and other implementations are the same as in Embodiment 1.

[0041] 1. Design conditions and requirements:

[0042] Change gas volume: 160273Nm 3 / h

[0043] Working pressure: 2.1MPa

[0044] Working temperature: 35~40℃

[0045] The gas composition is:

[0046] serial number

name

CO 2 %

CO%

H 2 %

O 2 %

N 2 %

CH 4 %

1

semi water gas

7.87

29.3

46.03

0.3

15.19

1.02

2

change gas

24.00

4~8

55.40

0

12.60

0.85

[0047] 2. Compared with the adiabatic shift reactor of the traditional full low-variation process, the present invention can bring the following energy saving:

[0048] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com