Pipette head box automatic-stacking-type storage box and using method thereof

A technology for tip boxes and storage boxes, which is applied in storage devices, transportation, and packaging. It can solve the problems of limited number of tip boxes and high precision requirements for manipulator motion control, and achieve stable and reliable opening and closing of trays, adding and removing. Use the effect of stable order and lower height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solution of the present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0051] The box body, tray, drive plate, brackets and baffles can be made of wear-resistant metal, and the surface of the drive plate sliding device should be self-lubricating.

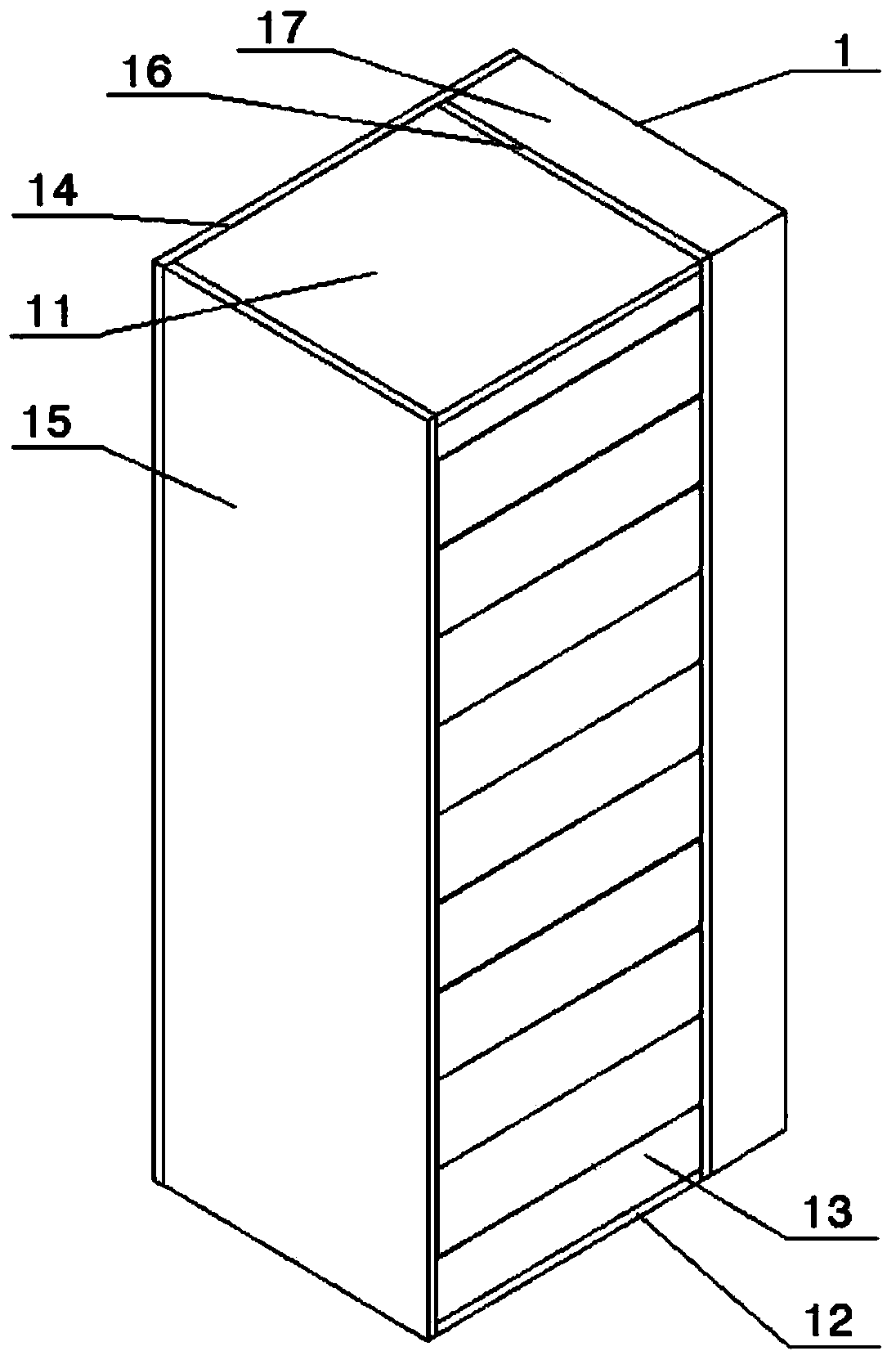

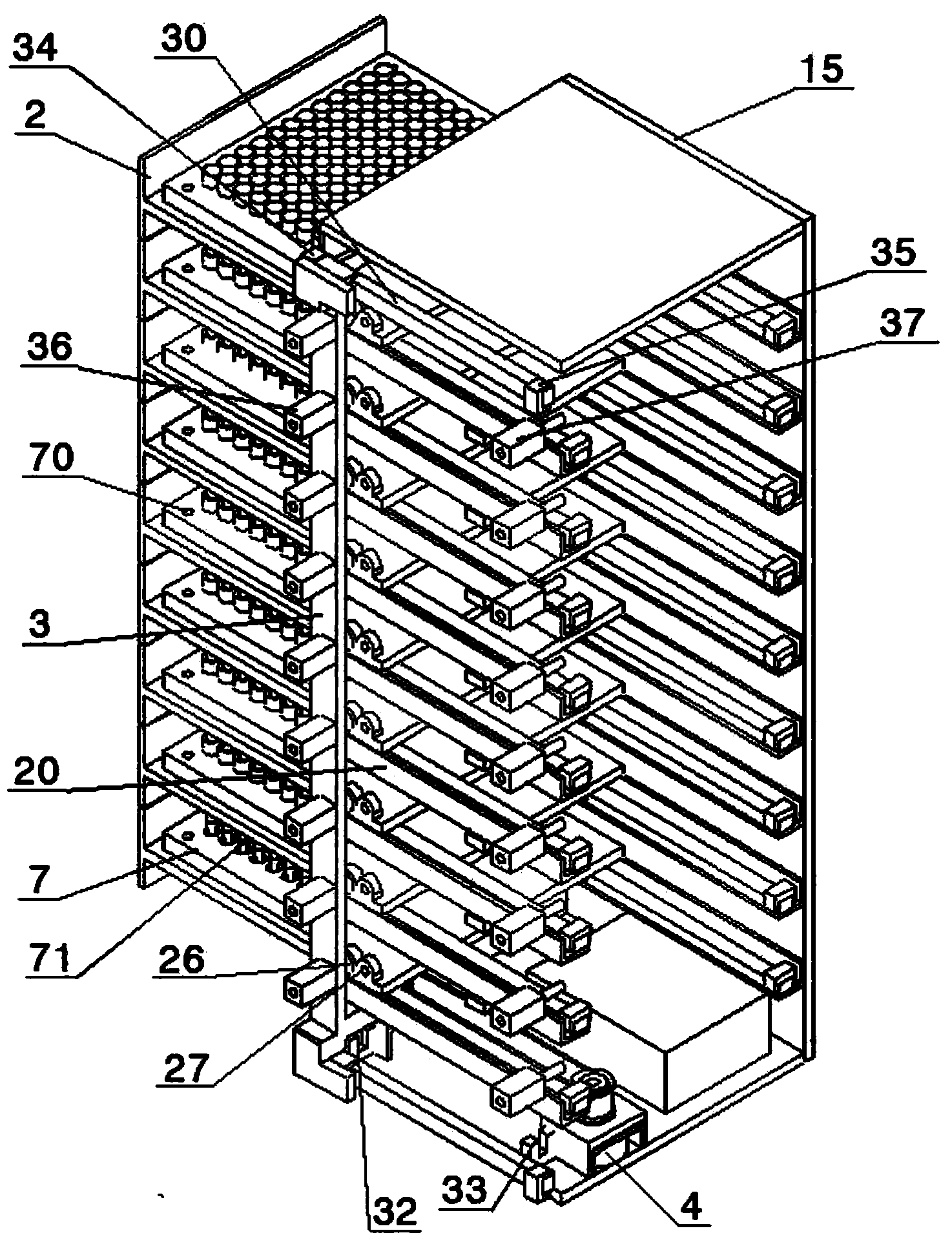

[0052] Such as Figure 1 to Figure 4 In the shown embodiment, the upper plate 11, the bottom plate 12, the front plate 13, the back plate 14, the left side plate 15, the inner side plate 16 and the right side plate 17 are connected by bolts to form a box body 1, and the box body 1 is made of aluminum alloy; The sliding brackets 20 on both sides of the layer tray 2 are respectively fixed on the left side plate 15 and the inner side plate 16. The sliding device 21 uses an alloy linear guide rail, and the two ends of the sliding device 21 are respectively provided with a mechanical limiter consisting of a front stopper 24 and a rear stopper 25. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com