Production technique of pharmaceutical gelatin

A production process and process technology, applied in the production process field of medicinal gelatin, can solve the problems of high viscosity drop rate, low product viscosity and high production cost, and achieve the effects of reducing waste and contamination, improving gelatin color and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

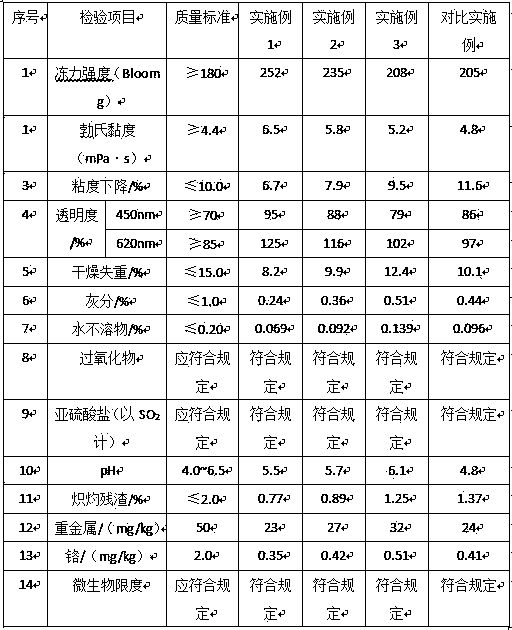

Examples

Embodiment 1

[0031] In this embodiment, 1 kg of pigskin (the collagen content of which is measured to be 256.4 g) is used for processing through the pretreatment process of the present invention, including the following steps:

[0032] (a) Skin cutting: use a leather cutter to cut the leather into strips, and transfer it to the washing tank with a delivery pump;

[0033] (b) Alkali treatment: add water to the leather, add 1.0% liquid caustic soda sodium hydroxide, and soak for 2 hours;

[0034] (c) Hydrogen peroxide pretreatment: add hydrogen peroxide with a concentration of 10% to the lye in (b) to treat the raw skin,

[0035] Soak at room temperature for 6 days;

[0036] (d) Separation: Use a separation system to separate skin water and recover liquid alkali;

[0037] (e) Water washing: wash the leather in the washing tank until the pH value of the solution is 6.5;

[0038] (f) Pickling: Add sulfuric acid to make the pH of the solution reach 2.1, and the soaking time is 18 hours;

[...

Embodiment 2

[0052] In this embodiment, 1 kg of cowhide (278.2 g of collagen content was measured) was used to carry out the process through the pretreatment process of the present invention.

[0053] row processing, including the following steps:

[0054] (a) Skin cutting: use a leather cutter to cut the leather into strips, and transfer it to the washing tank with a delivery pump;

[0055] (b) Alkali treatment: Add water to the leather, add 0.8% liquid caustic soda sodium hydroxide, and soak for 2 hours;

[0056] (c) Hydrogen peroxide pretreatment: add hydrogen peroxide with a concentration of 5% to the lye in (b) to treat the raw skin,

[0057] Soak at room temperature for 8 days;

[0058] (d) Separation: Use a separation system to separate skin water and recover liquid alkali;

[0059] (e) Water washing: wash the leather in the washing tank until the pH value of the solution is 7.2;

[0060] (f) Pickling: add sulfuric acid to make the pH of the solution reach 2.4, and the soaking t...

Embodiment 3

[0067] In this embodiment, 1 kg of cowhide (278.2 g of collagen content was measured) was used to carry out the process through the pretreatment process of the present invention.

[0068] row processing, including the following steps:

[0069] (a) Skin cutting: use a leather cutter to cut the leather into strips, and transfer it to the washing tank with a delivery pump;

[0070] (b) Alkali treatment: add water to the leather, add 0.9% liquid caustic soda sodium hydroxide, and soak for 2 hours;

[0071] (c) Hydrogen peroxide pretreatment: add hydrogen peroxide with a concentration of 20% to the lye in (b) to treat the raw skin,

[0072] Soak for 5 days at room temperature;

[0073] (d) Separation: Use a separation system to separate skin water and recover liquid alkali;

[0074] (e) Water washing: wash the leather in the washing tank until the pH value of the solution is 6.8;

[0075] (f) Pickling: Add sulfuric acid to make the pH of the solution reach 1.8, and the soaking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com