Magnetic bead separation device with adjustable magnetic flux

A technology of magnetic bead separation and magnetic flux, applied in stress-stimulated microbial growth methods, material inspection products, biochemical instruments, etc., can solve the problem of inconvenient transfer of liquids by pipettes, affecting the stability and reliability of magnetic separation, affecting the performance of workstations and Operation efficiency and other issues, to achieve the effect of avoiding multiple complicated operations, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

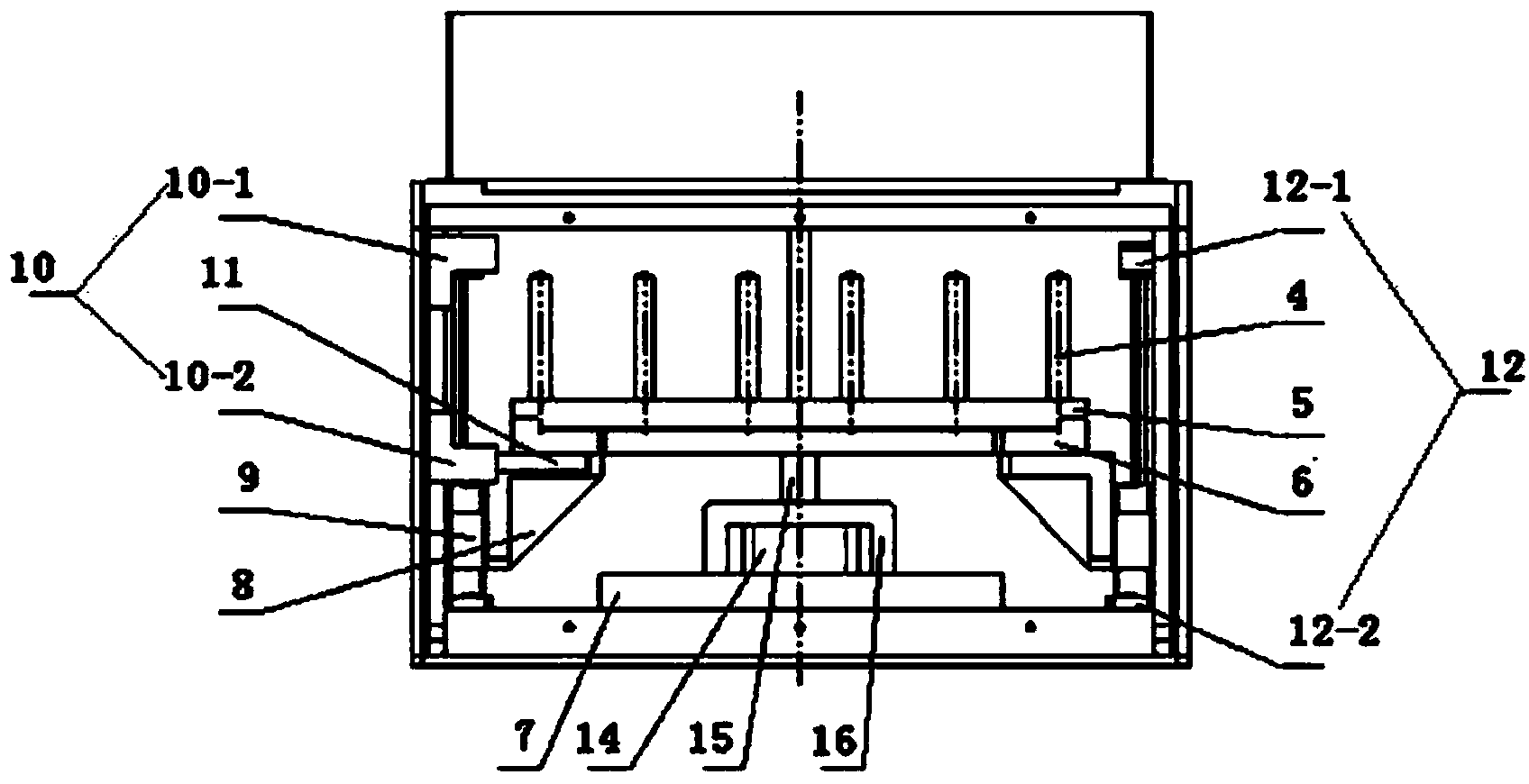

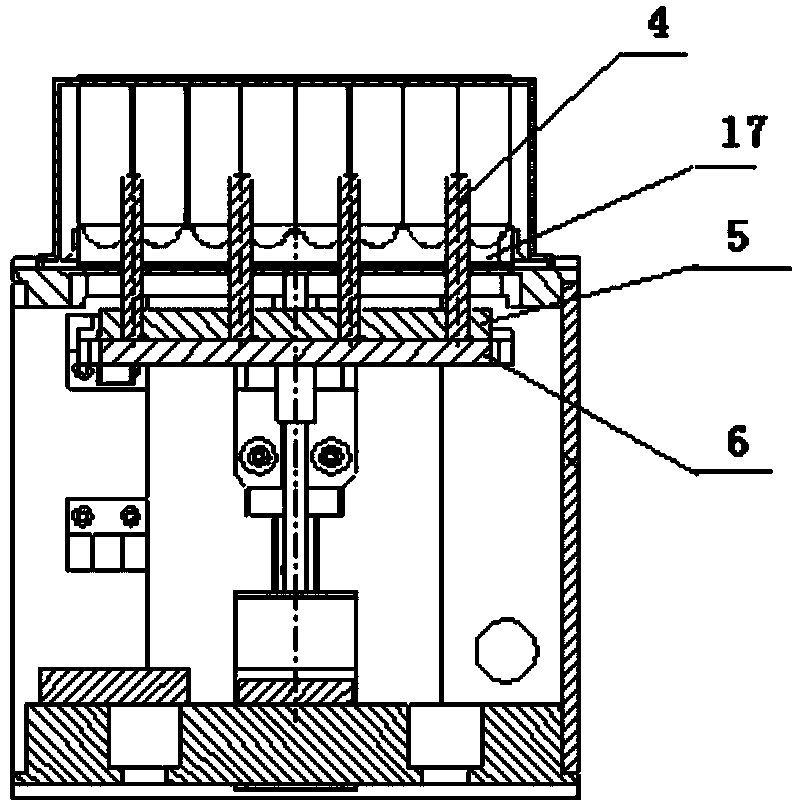

[0030] The technical solution of the present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

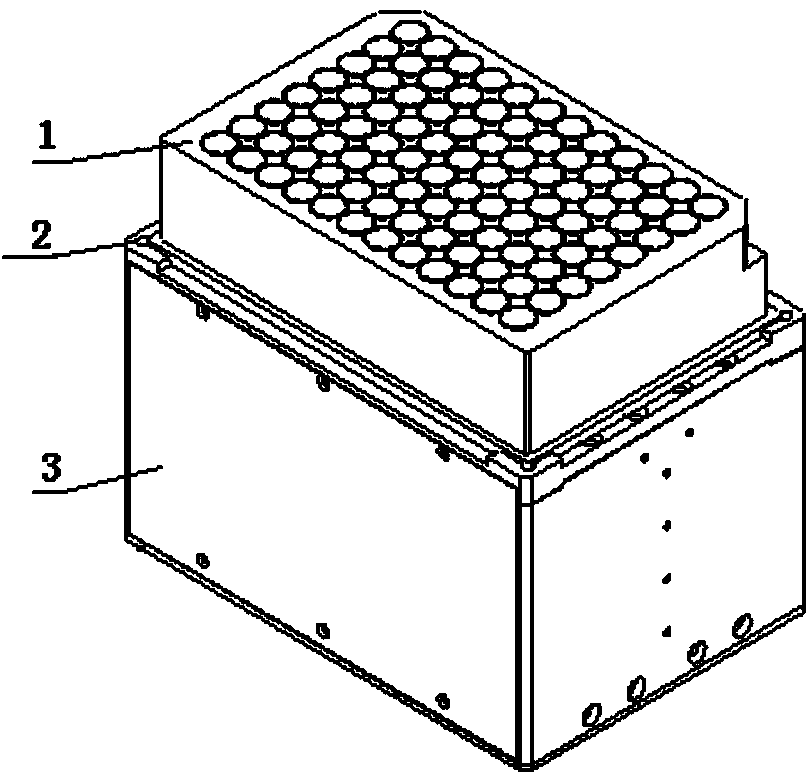

[0031] Such as figure 1 , shown in Fig. 2 (a), Fig. 2 (b), a kind of magnetic flux adjustable magnetic bead separation device of the present invention comprises microporous plate 1, microporous plate support 2, base 3, magnetic bar 4, magnetic bar Bracket 5, magnetic rod bracket positioning hole 5-1, floating bracket 6, electrical control module 7, connecting bracket 8, sliding device 9, limit switch 10, upper limit switch 10-1, lower limit switch 10-2, limit Position bar 11, limit block 12, upper limit block 12-1, lower limit block 12-2, linear stepper motor 14, lead screw nut 15, motor support 16 and heating device 17.

[0032] In this embodiment, the microwell plate 1 is a 96 microwell plate. The microporous plate 1 is installed on the microporous plate support 2, and the microporous plate support 2 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com