Preparation method of high silicon nickel-copper alloy casting

A technology for alloy castings, high-silicon-nickel-copper, applied in the field of preparation of high-silicon-nickel-copper alloy castings, can solve the problems of limited use, poor processing performance, low plasticity of alloy castings, etc., to reduce internal stress generation and process formability Good, the effect of alloy performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The alloy is smelted in a 10Kg vacuum induction furnace, and the alloy test rod is cast. The refining temperature is 1450°C, the refining time is 3min, the vacuum degree is 0.1Pa, and the pouring temperature is 1300°C.

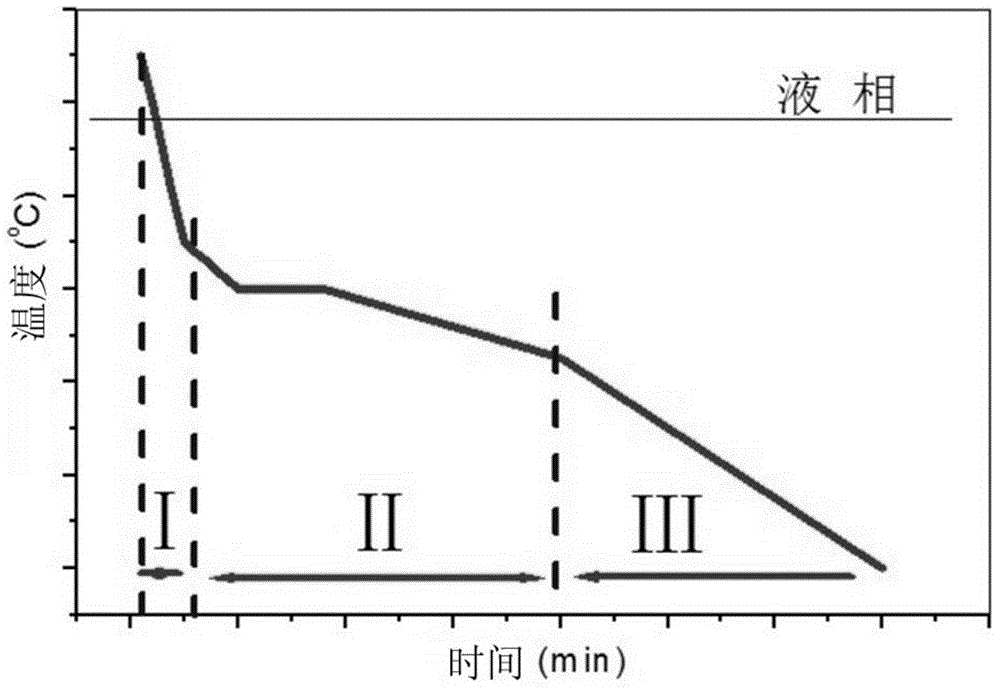

[0034] The solidification control process is adopted in the solidification process of the alloy test rod: the initial cooling rate is 120°C / s, after the casting temperature reaches 1000°C, the cooling rate is reduced to 0.04°C / s, when the alloy casting is cooled below 400°C, the casting is naturally After cooling to room temperature, the alloy solidification process curve is as follows figure 1 . The alloy composition of this embodiment is shown in Table 1.

[0035] Table 1 Composition of high-silicon-nickel-copper alloy (wt%)

[0036] chemical composition

Cu

Si

Fe

mn

C

Ni

Content (wt.%)

31.5

3.9

1.98

1.13

0.021

margin

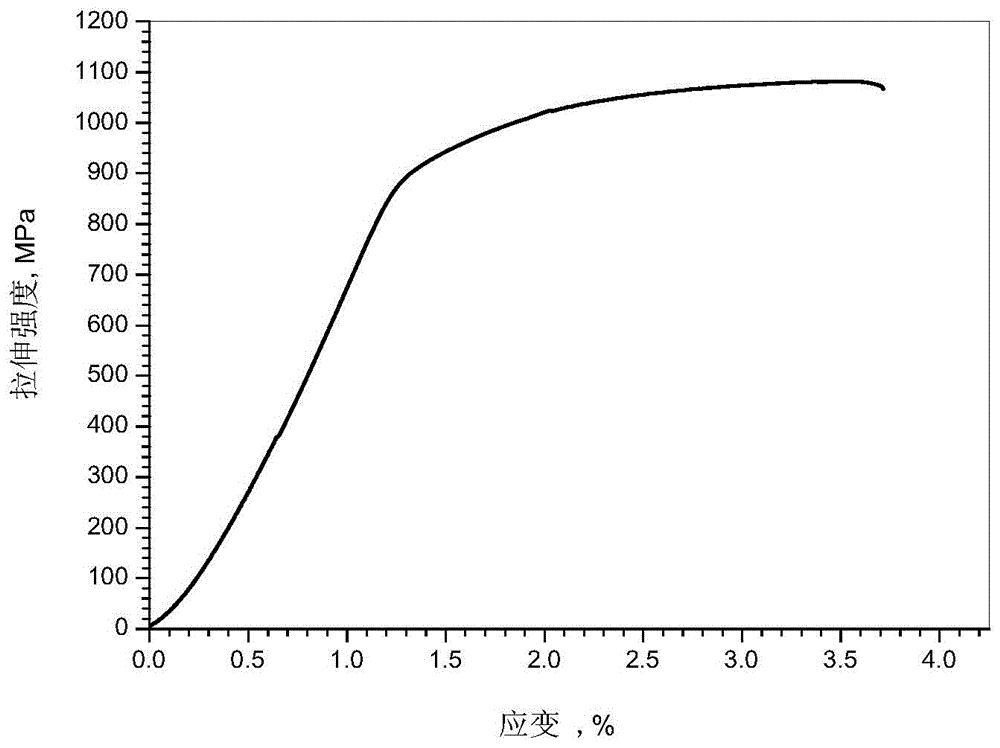

[0037] Table 2 is the tensile properties of the alloy cas...

Embodiment 2

[0049] The alloy composition of this embodiment is shown in Table 4.

[0050] Table 4 Composition of high-silicon-nickel-copper alloy (wt%)

[0051] chemical composition

Cu

Si

Fe

mn

C

Ni

Content (wt.%)

30.9

4.05

2.12

0.98

0.025

margin

[0052] The alloy adopts the solidification control process to cast and form the tensile test bar, and heat treatment at the same time, the process is as follows:

[0053] (1) The alloy is smelted in a 10Kg vacuum induction furnace, and the alloy test rod is cast. The refining temperature is 1480°C, the refining time is 5min, the vacuum degree is 0.1Pa, and the pouring temperature is 1280°C.

[0054] (2) The solidification control process is adopted in the solidification process of the alloy test rod: the initial cooling rate is 150 ° C / s, after the casting temperature reaches 1000 ° C, the cooling rate is reduced to 0.05 ° C / s, when the alloy casting is cooled to belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com