Processing method of 2024 aluminum alloy board

A technology of aluminum alloy sheet and processing method, which is applied in the field of aluminum alloy, can solve problems such as processing deformation, low corrosion resistance, residual stress on the surface and center of the sheet, achieve good mechanical properties, improve corrosion resistance, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

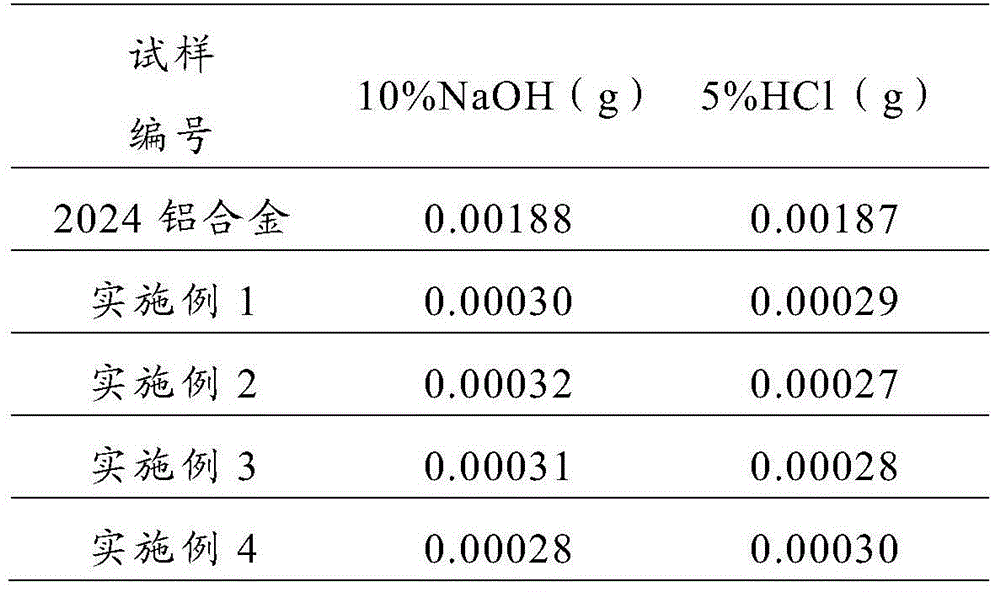

Examples

Embodiment 1

[0038] a) Take a 2024 aluminum alloy plate with a thickness of 15mm, quench the aluminum alloy plate, the temperature during quenching is 515°C, the holding time is 4 hours, and the cooling method is water cooling;

[0039] b) keeping the quenched 2024 aluminum alloy plate at -35°C for 8 hours;

[0040] c) Apply 3% tensile deformation to the 2024 aluminum alloy sheet in the thickness direction;

[0041] d) For the high-temperature aging treatment of the aluminum alloy plate after stretching and deformation, the temperature during the high-temperature aging treatment is 170° C., and the holding time is 10 hours.

Embodiment 2

[0043]a) Take a 2024 aluminum alloy plate with a thickness of 15mm, quench the aluminum alloy plate, the temperature during quenching is 515°C, the holding time is 4 hours, and the cooling method is water cooling;

[0044] b) keeping the quenched 2024 aluminum alloy plate at -40°C for 5 hours;

[0045] c) Apply 3% tensile deformation to the 2024 aluminum alloy sheet in the thickness direction;

[0046] d) For the high-temperature aging treatment of the aluminum alloy plate after stretching and deformation, the temperature during the high-temperature aging treatment is 160° C., and the holding time is 10 hours.

Embodiment 3

[0048] a) Take a 2024 aluminum alloy plate with a thickness of 15mm, quench the aluminum alloy plate, the temperature during quenching is 515°C, the holding time is 4 hours, and the cooling method is water cooling;

[0049] b) keeping the quenched 2024 aluminum alloy plate at -30°C for 8 hours;

[0050] c) Apply 2% tensile deformation to the 2024 aluminum alloy sheet in the thickness direction;

[0051] d) For the high-temperature aging treatment of the aluminum alloy plate after stretching and deformation, the temperature during the high-temperature aging treatment is 160° C., and the holding time is 10 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com