Powdered coal combustor for entrained-flow bed gasification furnace

A burner and gasifier technology, applied in the field of coal gasification, can solve the problems of difficult maintenance and disassembly of the water jacket structure, poor mixing effect, and falling off of the swirl sheet, etc., to achieve long-term stable operation and reduce high temperature Radiation area and intensity, effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

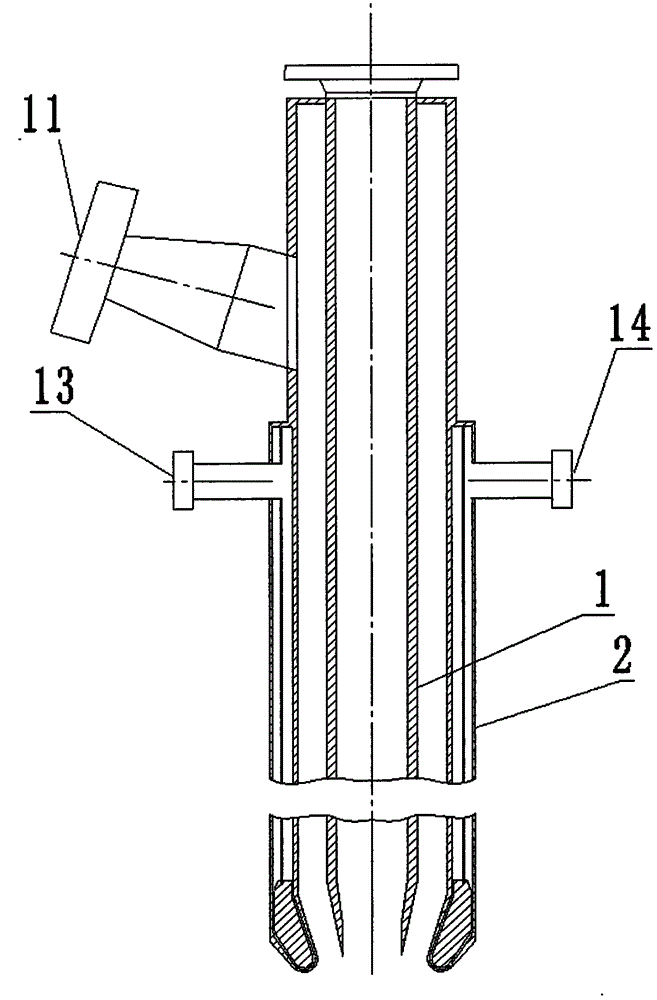

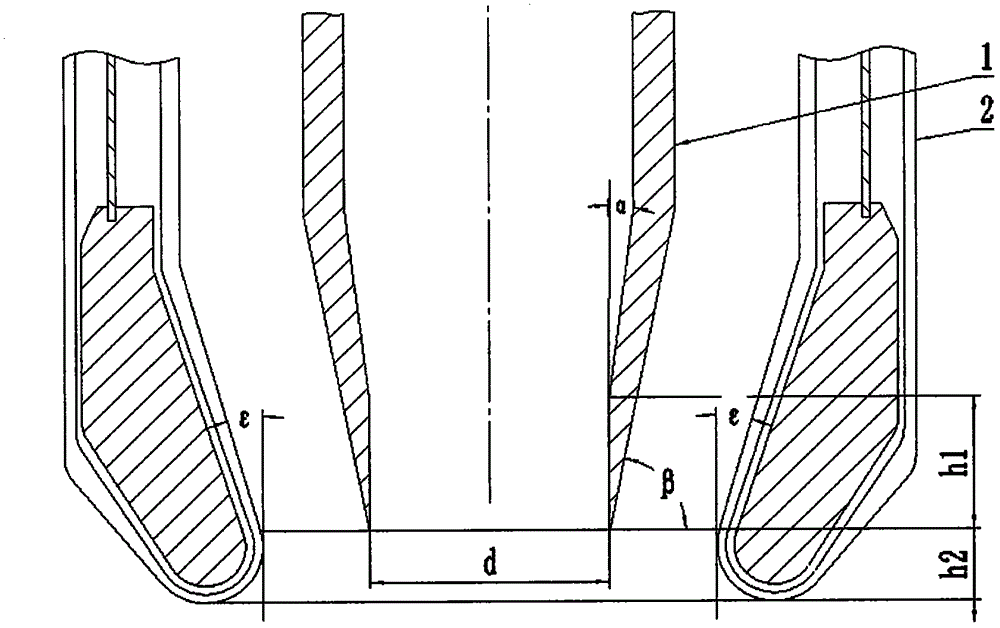

[0035] A preferred scheme of pulverized coal burner of the present invention sees figure 1 , comprising a central tube 1 and a peripheral tube 2 concentrically surrounding the central tube, the central tube 1 and the peripheral tube 2 are conically constricted on the side close to the fire surface, the central tube 1 is an oxidant channel, the outer wall of the central tube 1 and the peripheral The annular passage formed on the inner wall of the pipe 2 is a pulverized coal passage, and the peripheral pipe 2 is a cooling water jacket with a double-layer structure. The cooling water enters the inner layer of the jacket from the cooling water inlet 13 first, and then enters through the narrow passage at the nozzle part of the peripheral pipe 2. The outer side of the jacket and flows out from the cooling water outlet 14. figure 2 yes figure 1 The enlarged view of the nozzle section of the medium pulverized coal burner, in which, the inner contraction half angle α of the center t...

Embodiment 2

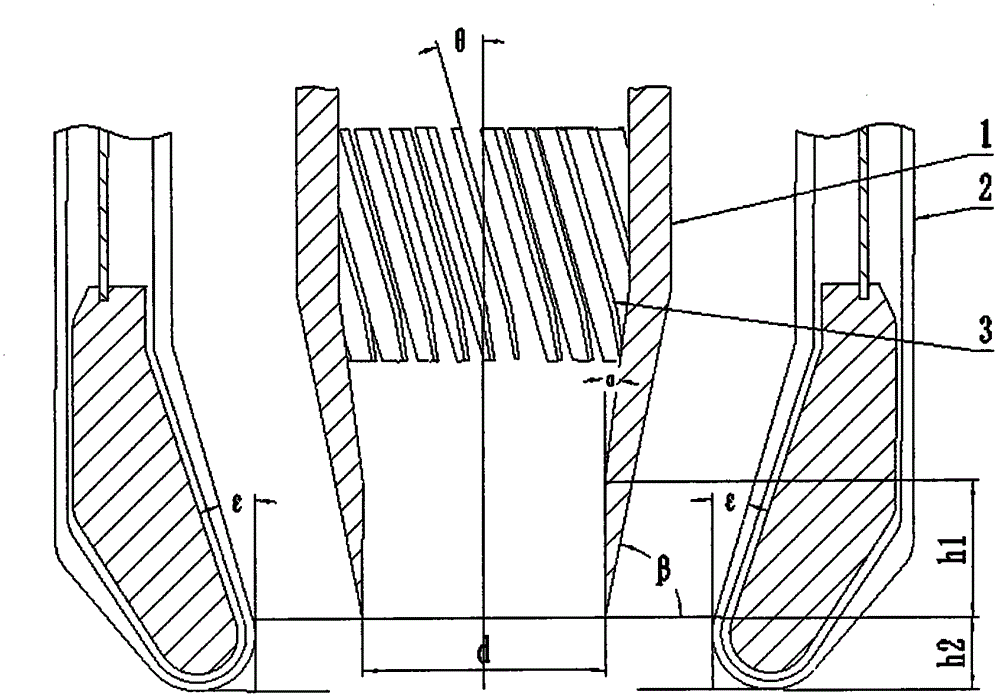

[0037] Another preferred solution of the pulverized coal burner of the present invention is that the pulverized coal burner includes a central tube 1 and a peripheral tube 2 concentrically surrounding the central tube, and the central tube 1 and the peripheral tube 2 are tapered on the side close to the fire surface The central tube 1 is the oxidant channel, the annular channel formed by the outer wall of the central tube 1 and the inner wall of the peripheral tube 2 is a pulverized coal channel, and the peripheral tube 2 is a cooling water jacket with a double-layer structure, and the cooling water enters from the cooling water inlet 13 first. The inner layer of the jacket enters the outer side of the jacket through the narrow channel at the spray head of the peripheral tube 2 and flows out through the cooling water outlet 14. Among them, the inner contraction half angle α of the central pipe 1 nozzle is 20°, the outer inclination β is 80°, the inner contraction half angle ε o...

Embodiment 3

[0039] Another preferred solution of the pulverized coal burner of the present invention is that the pulverized coal burner includes a central tube 1 and a peripheral tube 2 concentrically surrounding the central tube, and the central tube 1 and the peripheral tube 2 are tapered on the side close to the fire surface The central tube 1 is the oxidant channel, the annular channel formed by the outer wall of the central tube 1 and the inner wall of the peripheral tube 2 is a pulverized coal channel, and the peripheral tube 2 is a cooling water jacket with a double-layer structure, and the cooling water enters from the cooling water inlet 13 first. The inner layer of the jacket enters the outer side of the jacket through the narrow channel at the spray head of the peripheral tube 2 and flows out through the cooling water outlet 14. Among them, the inner contraction half angle α of the central tube 1 nozzle is 15°, the outer inclination β is 75°, the inner contraction half angle ε o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com