Automatic LCD screen detecting cabinet based on machine vision

A machine vision and LCD screen technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of false detection rate, high missed detection rate of detection equipment, assembly line detection in combination with production lines, and low detection efficiency, etc., to achieve Improved automation level, stable and reliable communication process, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

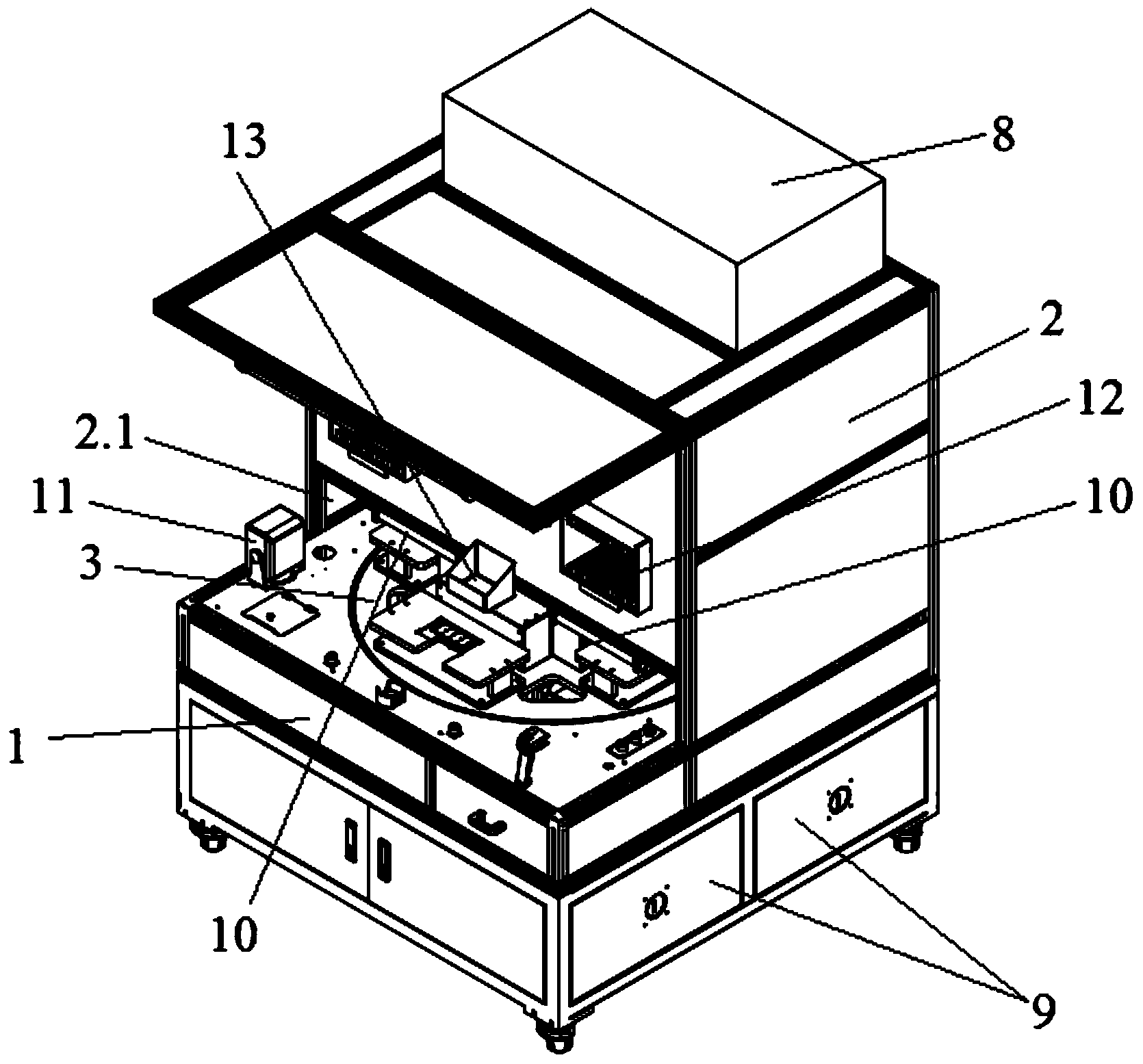

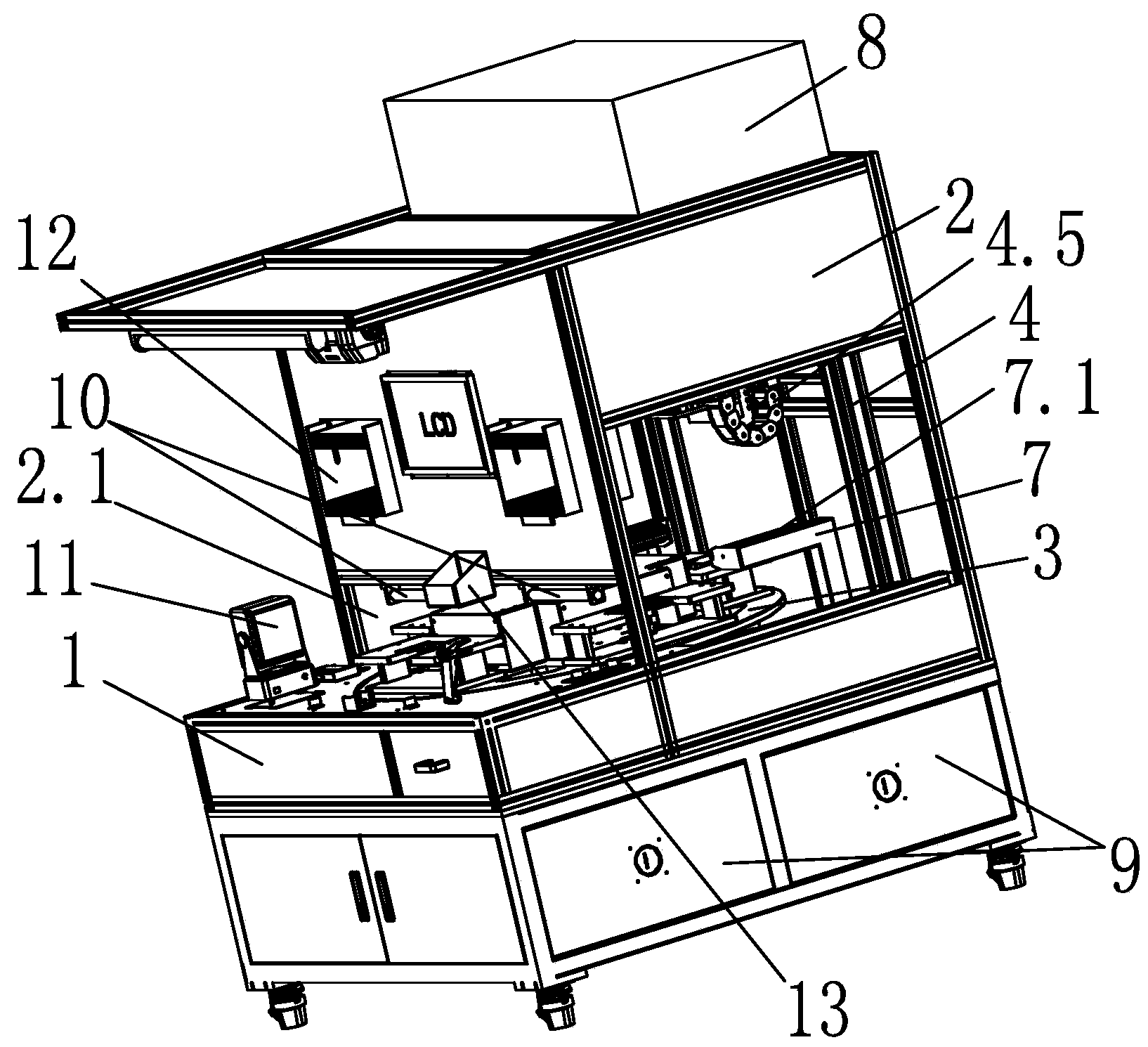

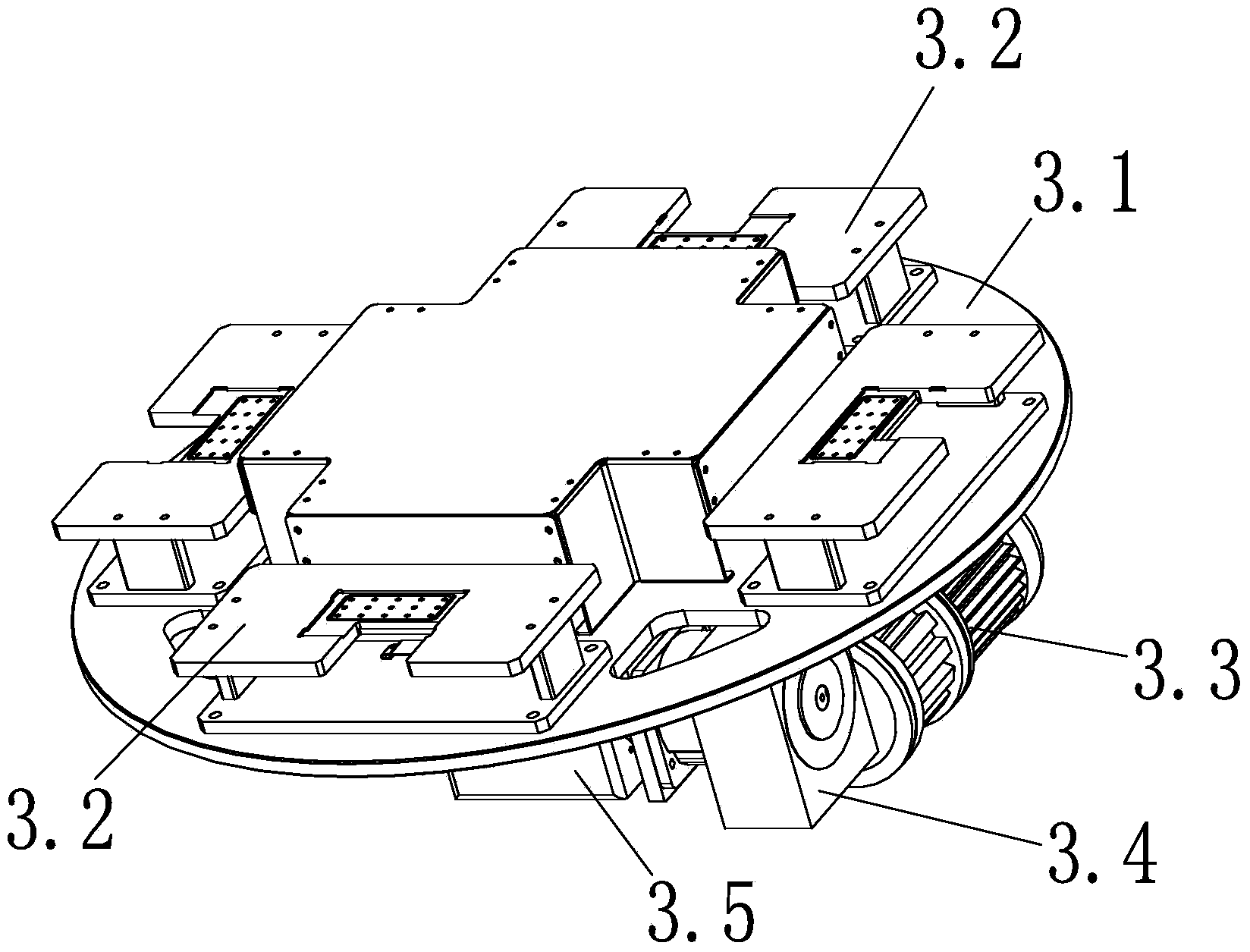

[0016] Such as Figure 1~6 The machine vision-based LCD screen automatic detection machine is shown, which includes a machine base 1, a dark room 2 composed of a front panel, a back panel, a top panel and two side panels, and a multi-station installed on the top of the machine base 1 Turntable system 3, PG automatic point screen system installed on the multi-station turntable system 3 and capable of sending test signals to the LCD screen 6 to be tested 5, installed on the top of the machine base 1 and capable of defect detection of the LCD screen 6 to be tested The machine vision automatic adjustment system 4, is arranged in the darkroom 2 and provides a light source 7.1 for detection illumination to the LCD screen 6 to be tested, wherein the top of the machine base 1 is fixedly connected to the bottom of the darkroom 2, and is located at the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com