An integrated multi-stage high-voltage pulse isolation inductor

A high-voltage pulse and inductance technology, applied in the direction of transformer/inductor coil/winding/connection, preventing/reducing unwanted electrical/magnetic effects, etc. The system has problems such as reduced voltage withstand strength, reduced circuit stability and reliability, etc., to achieve the effect of compact structure, reduced volume and weight, and prevention of flashover along the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

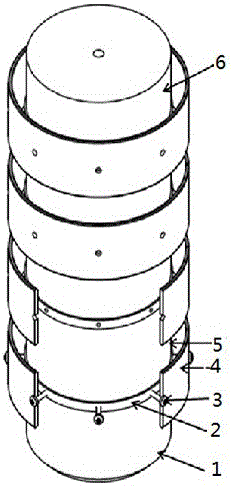

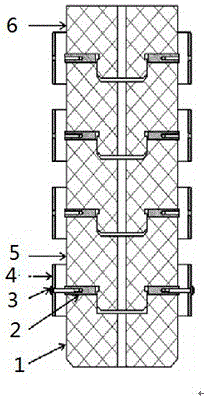

[0025] Such as figure 1 As shown, the main part of the present invention is composed of a top insulating joint, a bottom insulating joint and several insulating joints connected as a whole.

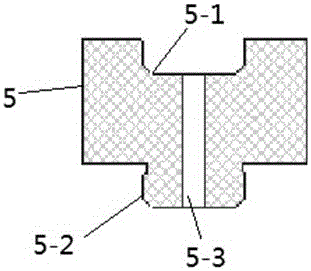

[0026] Such as image 3 As shown, the exterior of the insulating connection joint is cylindrical, the center of the upper surface is a concave part, and a certain space is recessed downward, and the center of the lower surface of the insulating connection joint protrudes outward. Both the concave part on the upper surface of the insulating joint and the convex part on the lower surface are coaxial with the center of the insulating joint.

[0027] Such as Figure 4 As shown, the top insulation connection section and the image 3 The only difference between the insulating joints in is that the upper surface of the top insulating joint is a smooth plane without concave parts.

[0028] Such as Figure 5 As shown, the bottom insulation connection section and the image 3 The only differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com