Device and method for conveying preforms

A technology for prefabricated blanks and a conveying device, which is applied in the field of machine devices, can solve the problems of increasing the throughput of the prefabricated blanks, and achieve the effect of increasing the throughput.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

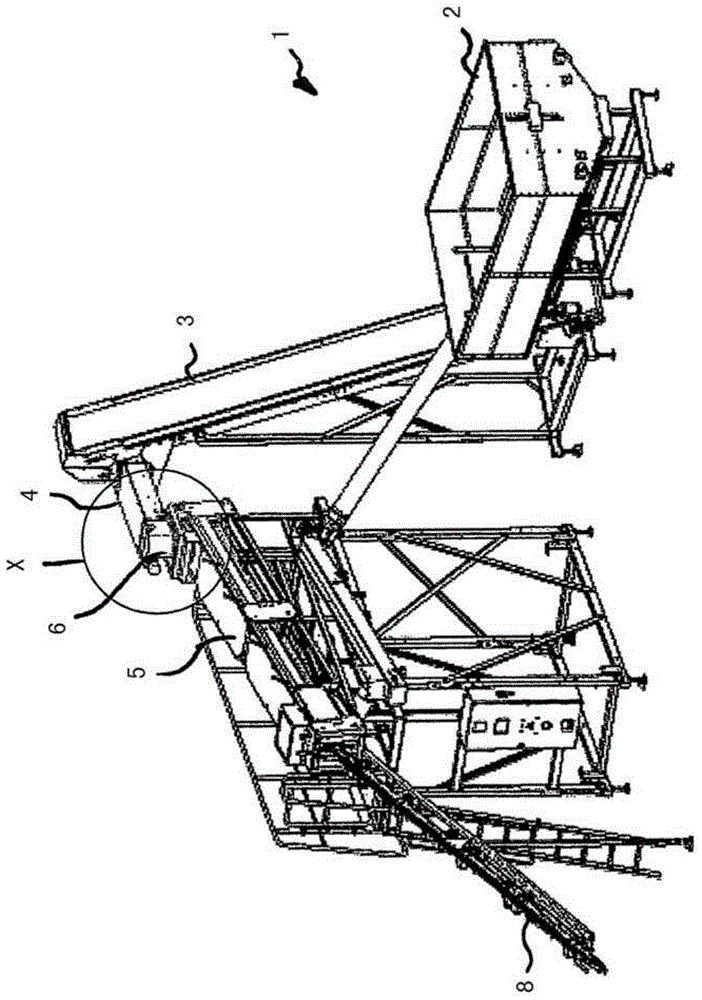

[0028] figure 1A device 1 for feeding preforms to a blow molding machine, for example for producing PET bottles, is shown. The device comprises a collection container 2 in which a stock of preforms is provided. The preforms are transported from the collection container 2 via a vertical conveyor 3 to the input of the conveyor 4 . The other end of the conveyor device 4 , namely the output end, is arranged above a sorting device 5 , wherein, for an orderly and as disturb-free delivery of the preforms from the conveyor device 4 to the sorting device 5 , there are two The supply device 6 arranged between. From the sorting device 5 the preforms are sorted to a second conveying device 8 by means of which the preforms are conveyed into a blow molding machine (not shown).

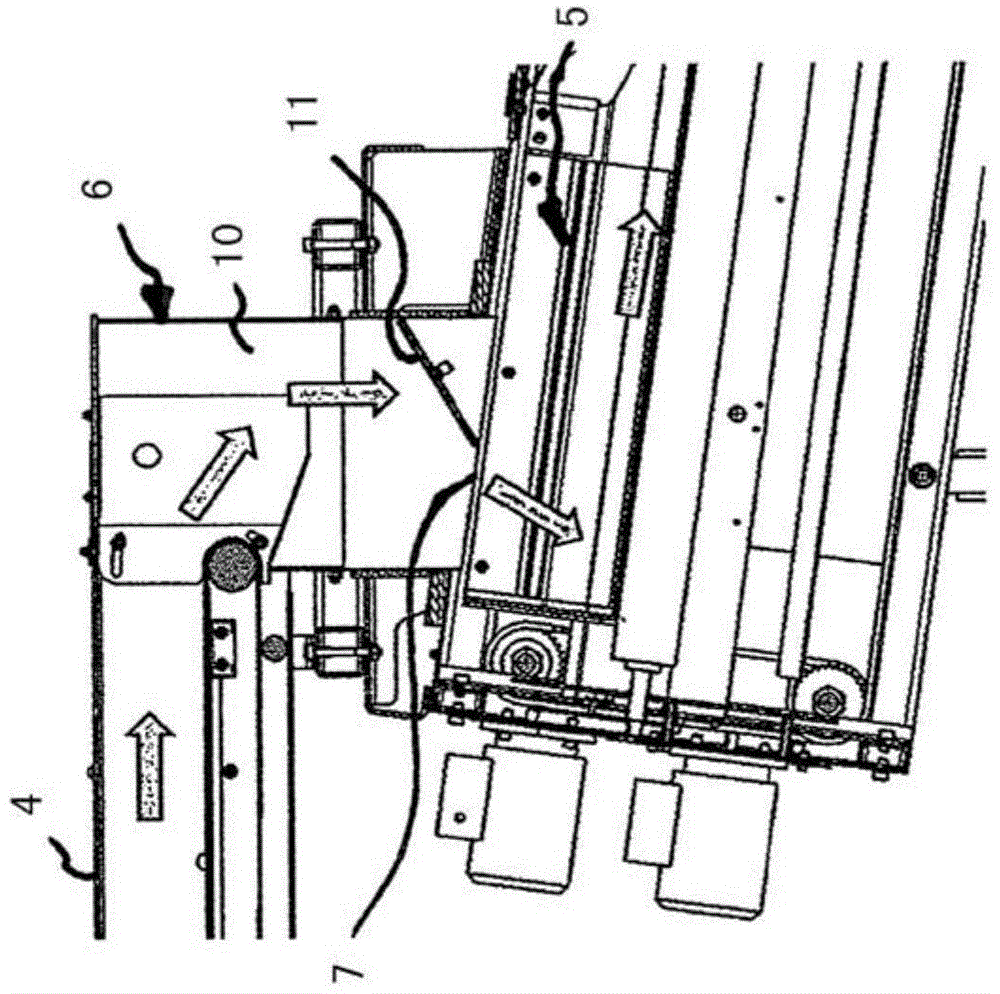

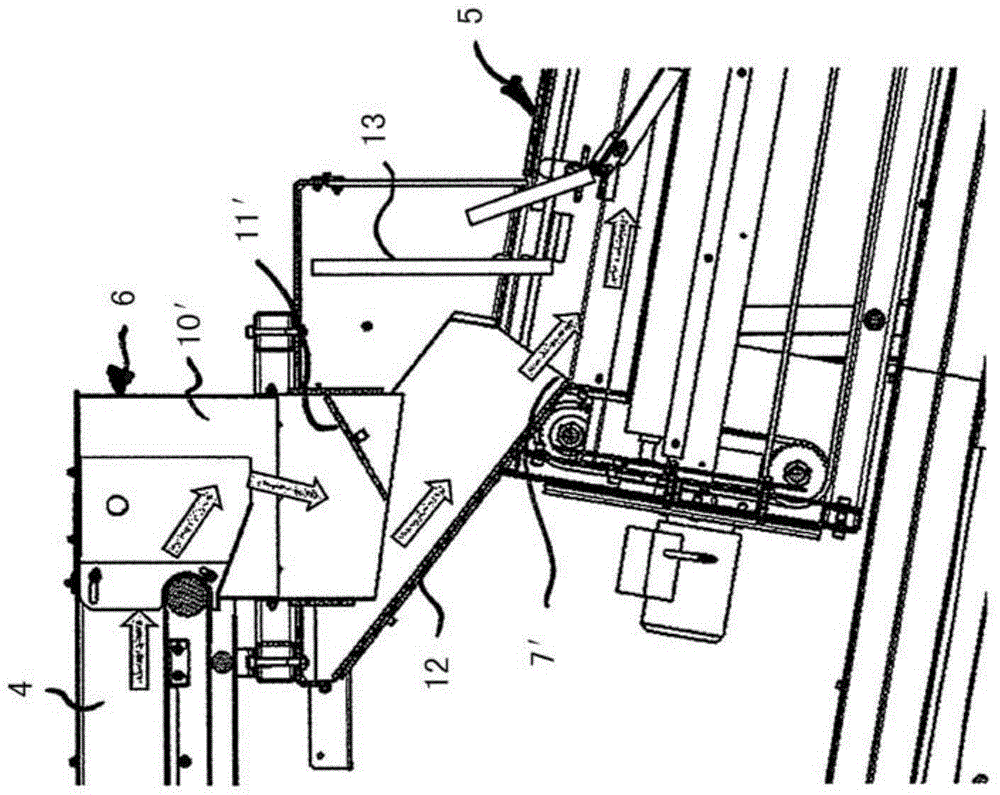

[0029] In Figure 2 is shown the figure 1 The cross-section of the side view of the detail X shown in , wherein the flow direction of the preforms is each indicated by means of the drawn arrows.

[0030] After r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com