Intra-articular liquid-solid composite lubricating agent and preparation method

A compound lubricant and intra-articular technology, applied in the field of biomedical engineering, can solve the problems that liquid lubricants have no obvious anti-friction effect and cannot effectively reduce cartilage friction damage, etc., achieve good anti-cartilage damage effect and restore knee joint function , increase the effect of joint activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing a liquid-solid composite lubricant in a joint, comprising the steps of:

[0023] Graphene oxide was prepared by the improved Hummers method, the graphene oxide was lamellar, the particle size was about 90nm, and the purity was 99.99%;

[0024] Graphene oxide was added to sodium hyaluronate with a molecular weight of 1.5 million to a concentration of 30 μg / ml, ultrasonicated for 0.5 h at 60°C to disperse evenly, and the composite lubricant was balanced to 25°C before use.

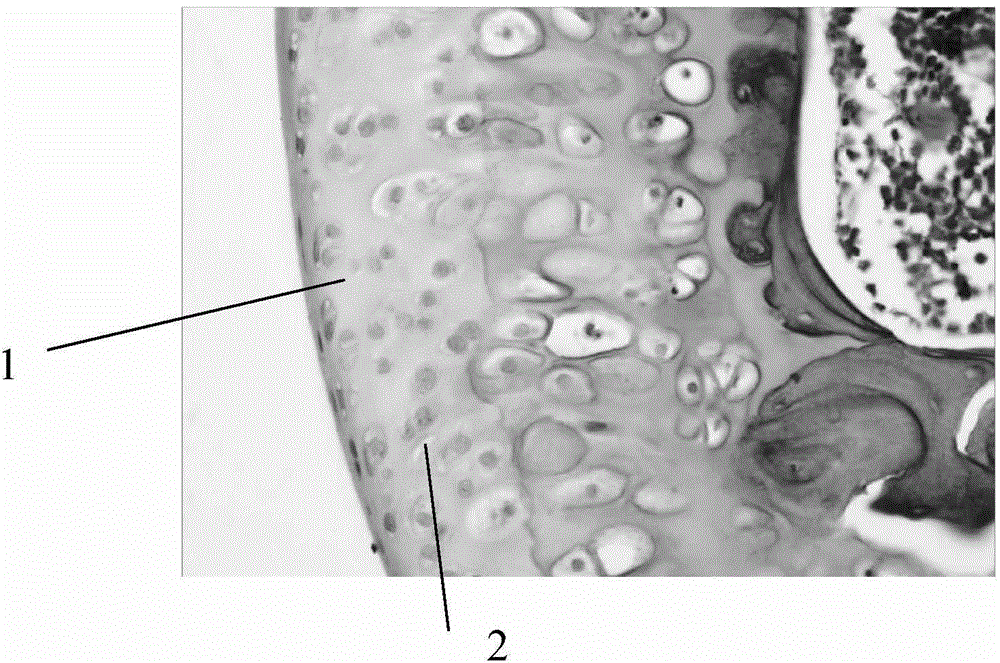

[0025] Male SD rats, weighing 200±10 g, were purchased from Tianjin Shanchuanhong Experimental Animal Technology Co., Ltd., license number SCXK (Jin) 2009-0001, production batch number: 20120617. Healthy male SD rats were selected, and their normal articular cartilage slices were as follows: figure 1 shown. According to 0.3g·kg -1 Body weight was anesthetized with 10% chloral hydrate ip, loaded with 35% poloxamer drug carrier and 4% papain to make thermosensitive in situ gel ...

Embodiment 2

[0028] A method for preparing a liquid-solid composite lubricant in a joint, comprising the steps of:

[0029] Using the Offeman method to prepare graphene oxide, the graphene oxide is lamellar, the particle size is about 110nm, and the purity is 99.9%;

[0030] Graphene oxide was added to sodium hyaluronate with a molecular weight of 800,000 to a concentration of 50 μg / ml, ultrasonicated for 1 hour at 20°C to disperse evenly, and the composite lubricant was balanced to 25°C before use.

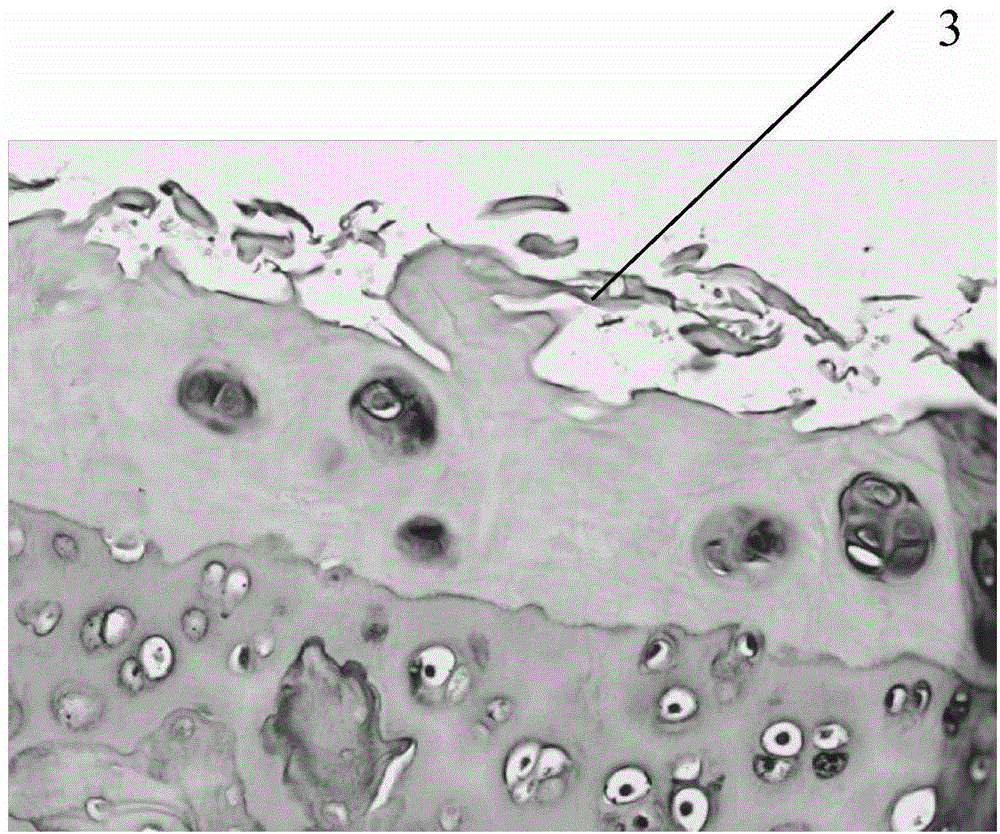

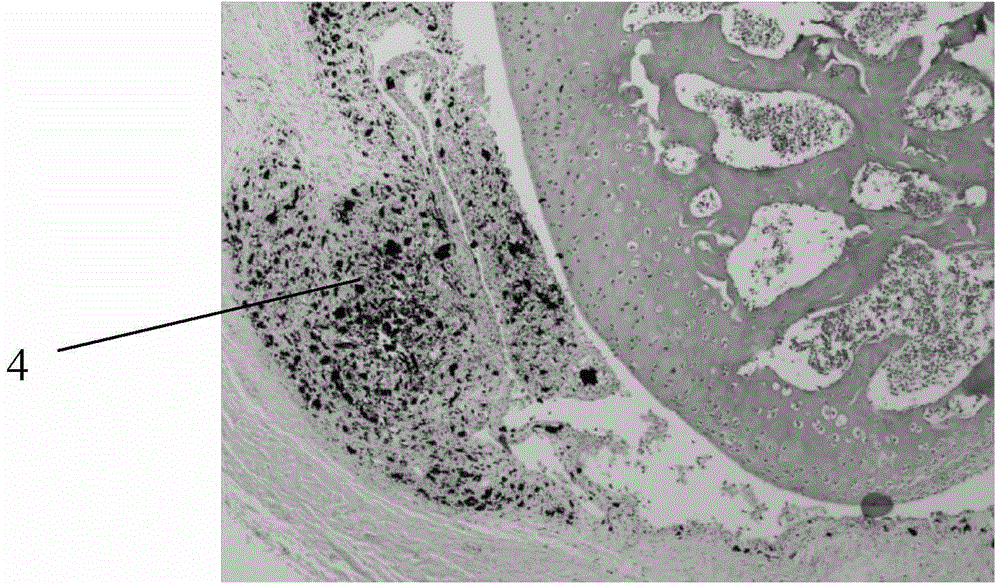

[0031] Male SD rats, weighing 200±10 g, were purchased from Tianjin Shanchuanhong Experimental Animal Technology Co., Ltd., license number SCXK (Jin) 2009-0001, production batch number: 20120617. Choose healthy male SD rats, according to 0.3g·kg -1 Body weight was anesthetized with 10% chloral hydrate ip, loaded with 35% poloxamer drug carrier and 4% papain to make thermosensitive in situ gel controlled release agent, according to the dose of 0.05ml (1.6U) / joint, bilateral Inject into the k...

Embodiment 3

[0034] A method for preparing a liquid-solid composite lubricant in a joint, comprising the steps of:

[0035] Purchase non-toxic graphene oxide, graphene oxide is lamellar, the particle size is about 120nm, and the purity is 99.999%;

[0036] Graphene oxide was added to sodium hyaluronate with a molecular weight of 2.2 million to a concentration of 20 μg / ml, ultrasonicated for 2 hours at 15°C to disperse evenly, and the composite lubricant was balanced to 25°C before use.

[0037] Male SD rats, weighing 200±10 g, were purchased from Tianjin Shanchuanhong Experimental Animal Technology Co., Ltd., license number SCXK (Jin) 2009-0001, production batch number: 20120617. Choose healthy male SD rats, according to 0.3g·kg -1 Body weight was anesthetized with 10% chloral hydrate ip, loaded with 35% poloxamer drug carrier and 4% papain to make thermosensitive in situ gel controlled release agent, according to the dose of 0.05ml (1.6U) / joint, bilateral Inject into the knee joint, act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com