A liquid-solid composite lubricant in joints and its preparation method

A compound lubricant and intra-articular technology, which is applied in the field of biomedical engineering, can solve the problems of ineffective reduction of cartilage friction damage and the insignificant effect of liquid lubricant on friction reduction, so as to achieve good anti-cartilage damage effect and restore knee joint function. , the effect of slowing down consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing a liquid-solid composite lubricant in a joint, comprising the steps of:

[0023] Graphene oxide was prepared by the improved Hummers method, the graphene oxide was lamellar, the particle size was about 90nm, and the purity was 99.99%;

[0024] Graphene oxide was added to sodium hyaluronate with a molecular weight of 1.5 million to a concentration of 30 μg / ml, ultrasonicated for 0.5 h at 60°C to disperse evenly, and the composite lubricant was balanced to 25°C before use.

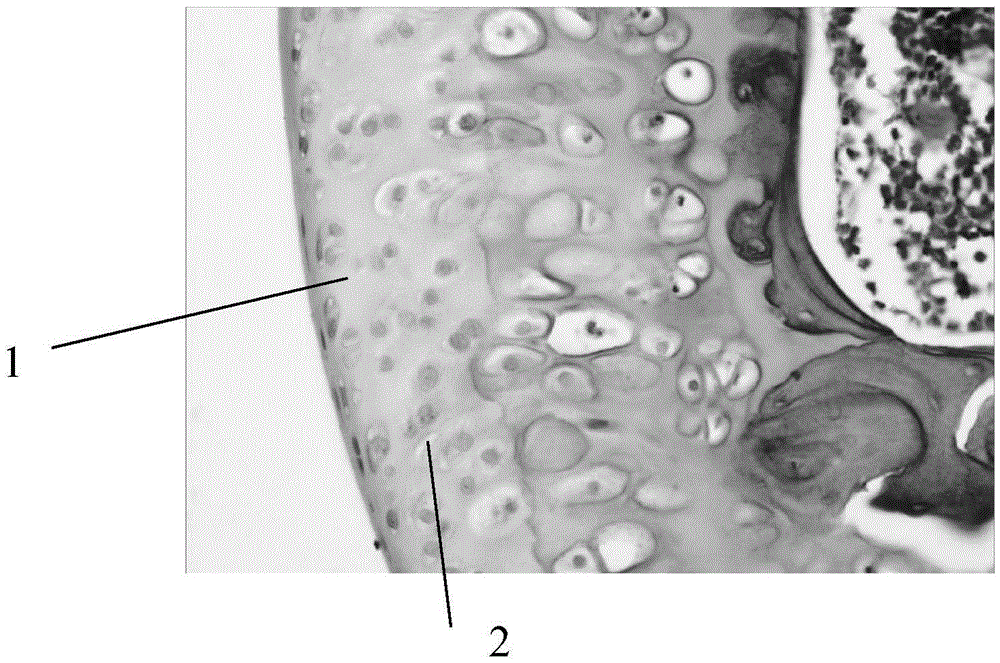

[0025] Male SD rats, weighing 200±10 g, were purchased from Tianjin Shanchuanhong Experimental Animal Technology Co., Ltd., license number SCXK (Jin) 2009-0001, production batch number: 20120617. Healthy male SD rats were selected, and their normal articular cartilage slices were as follows: figure 1 shown. According to 0.3g·kg -1 Body weight was anesthetized with 10% chloral hydrate ip, loaded with 35% poloxamer drug carrier and 4% papain to make thermosensitive in situ gel ...

Embodiment 2

[0028] A method for preparing a liquid-solid composite lubricant in a joint, comprising the steps of:

[0029] Using the Offeman method to prepare graphene oxide, the graphene oxide is lamellar, the particle size is about 110nm, and the purity is 99.9%;

[0030] Graphene oxide was added to sodium hyaluronate with a molecular weight of 800,000 to a concentration of 50 μg / ml, ultrasonicated for 1 hour at 20°C to disperse evenly, and the composite lubricant was balanced to 25°C before use.

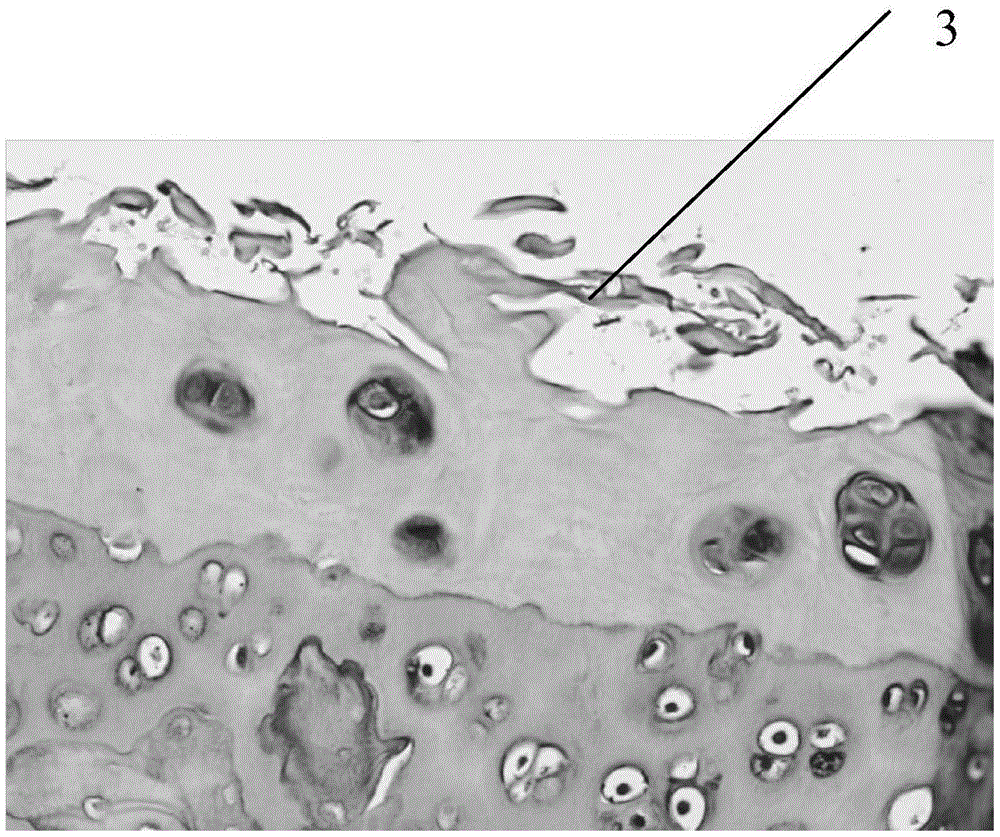

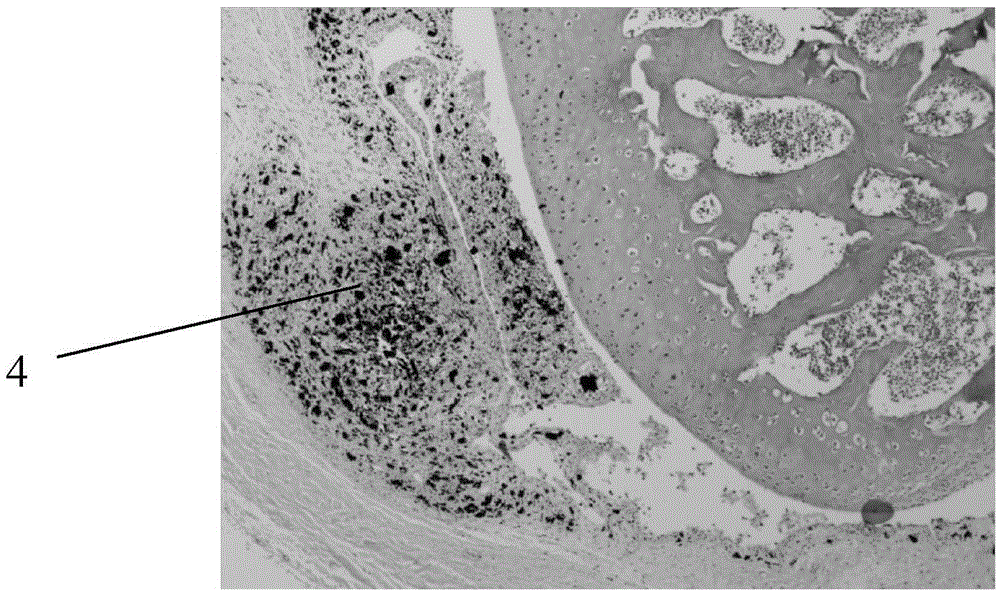

[0031] Male SD rats, weighing 200±10 g, were purchased from Tianjin Shanchuanhong Experimental Animal Technology Co., Ltd., license number SCXK (Jin) 2009-0001, production batch number: 20120617. Choose healthy male SD rats, according to 0.3g·kg -1 Body weight was anesthetized with 10% chloral hydrate ip, loaded with 35% poloxamer drug carrier and 4% papain to make thermosensitive in situ gel controlled release agent, according to the dose of 0.05ml (1.6U) / joint, bilateral Inject into the k...

Embodiment 3

[0034] A method for preparing a liquid-solid composite lubricant in a joint, comprising the steps of:

[0035] Purchase non-toxic graphene oxide, graphene oxide is lamellar, the particle size is about 120nm, and the purity is 99.999%;

[0036] Graphene oxide was added to sodium hyaluronate with a molecular weight of 2.2 million to a concentration of 20 μg / ml, ultrasonicated for 2 hours at 15°C to disperse evenly, and the composite lubricant was balanced to 25°C before use.

[0037] Male SD rats, weighing 200±10 g, were purchased from Tianjin Shanchuanhong Experimental Animal Technology Co., Ltd., license number SCXK (Jin) 2009-0001, production batch number: 20120617. Choose healthy male SD rats, according to 0.3g·kg -1 Body weight was anesthetized with 10% chloral hydrate ip, loaded with 35% poloxamer drug carrier and 4% papain to make thermosensitive in situ gel controlled release agent, according to the dose of 0.05ml (1.6U) / joint, bilateral Inject into the knee joint, act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com