Double-liquid desulfurization and dust removal process for glass kiln flue gas

A desulfurization and dust removal, dual-liquid technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of high operating cost, expensive desulfurization agent, affecting the long-term stable operation of desulfurization, etc., to shorten the time and improve desulfurization. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

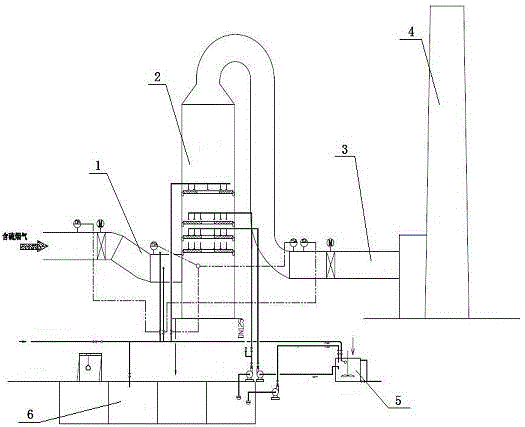

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

[0018] like figure 1 As shown, the flue gas enters the desulfurization tower from the entrance of the lower part of the tower through the smoke inlet flue 1, and in the desulfurization tower 2, it undergoes SO 2 Absorption reaction and dust capture, and finally enter the chimney 4 from the flue 3 at the upper part of the tower. Among them, in the desulfurization tower 2, the desulfurization liquid is recycled in different areas:

[0019] (1) There are three spray layers in the desulfurization tower 1. The spray liquid sprayed from the upper layer and the bottom layer is an acidic desulfurization liquid with a pH value of 5.0~5.5, which reacts with flue gas to absorb sulfur dioxide and prevent calcium sulfite formation. Scale; the spray liquid sprayed from the middle layer is a desulfurization liquid with a pH value of 8-9, which absorbs sulfur dioxide in contact with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com