A kind of preparation method of titanium oxide-sepiolite-activated carbon composite carrier

A composite carrier, sepiolite technology, applied in catalyst carriers, chemical instruments and methods, chemical/physical processes, etc., to achieve the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

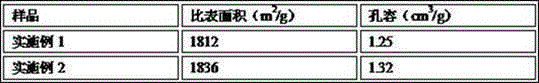

Embodiment 1

[0017] Get the wheat straw of 100 weight parts, through crushing, after pulverizing with superfine pulverizer and refinement with superfine pulverizer, obtain particle size and be the powder particle of 325 meshes;

[0018] Take 80 parts by weight of sepiolite, pulverize it with a pulverizer, and sieve it. Put the sieved powder particles in a muffle furnace, raise the temperature to 250° C. at a heating rate of 5° C. / min, keep it warm for 1 hour, and cool it down. After reaching room temperature, fully soak the calcined powder with HCl solution for 2 hours, then filter and wash to obtain activated modified sepiolite;

[0019] Take 50ml of butyl titanate, add 150ml of ethanol to it while stirring, and then add 10ml of HNO 3 and 10ml of distilled water, mixed and stirred for 2 hours to obtain a titanium dioxide sol, and the activated modified sepiolite obtained in the previous steps was added to the sol, stirred thoroughly for 1 hour, and then the mixture was baked in a muffle f...

Embodiment 2

[0021] Get 100 parts by weight of wheat straw, after crushing, pulverizing with a superfine pulverizer and refining with a superfine pulverizer, to obtain a particle size of 500 mesh powder particles;

[0022] Take 80 parts by weight of sepiolite, pulverize it with a pulverizer, and sieve it. Put the sieved powder particles in a muffle furnace, raise the temperature to 250° C. at a heating rate of 5° C. / min, keep it warm for 1 hour, and cool it down. After reaching room temperature, fully soak the calcined powder with HCl solution for 2 hours, then filter and wash to obtain activated modified sepiolite;

[0023] Take 50ml of butyl titanate, add 150ml of ethanol to it while stirring, and then add 10ml of HNO 3 and 10ml of distilled water, mixed and stirred for 2 hours to obtain a titanium dioxide sol, and the activated modified sepiolite obtained in the previous steps was added to the sol, stirred thoroughly for 1 hour, and then the mixture was baked in a muffle furnace at 500°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com