Method for preparing high dielectric loss titanium silicon carbon microwave absorbent powder

A technology of microwave absorbing agent and titanium silicon carbon is applied in the field of preparation of high dielectric loss titanium silicon carbon powder microwave absorbing agent, which can solve the problems of low microwave dielectric loss and low purity, and achieve the absorption frequency bandwidth and the preparation process. Simple and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

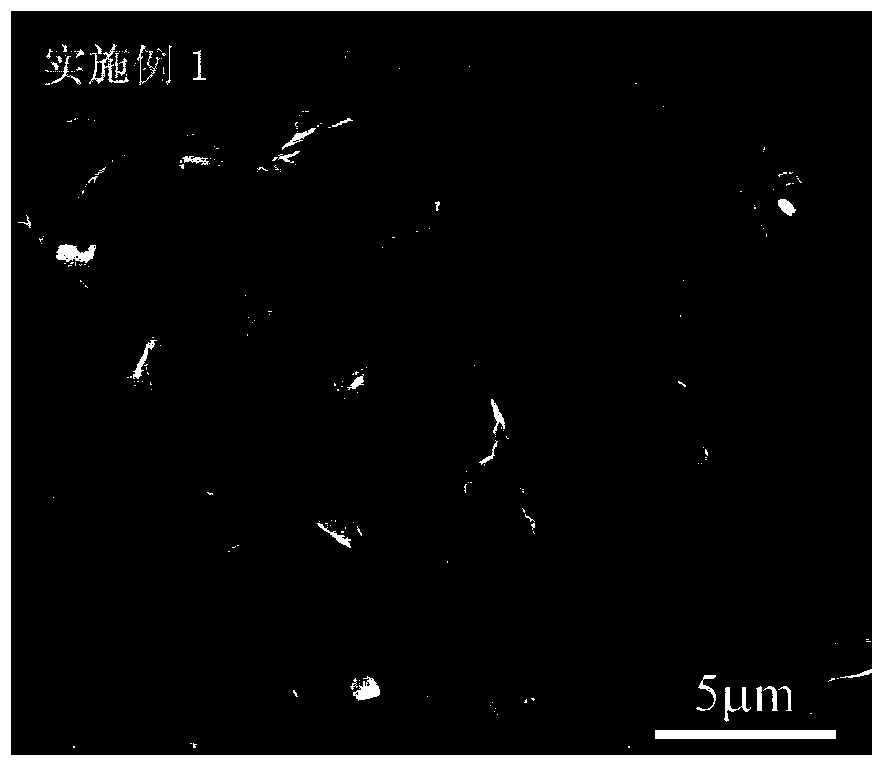

Embodiment 1

[0050] Mole ratio is n Ti :n Si :n Al :n TiC =2:1.8:0.4:3 Weigh titanium powder Ti, silicon powder Si, aluminum powder Al and titanium carbide powder TiC respectively, wherein, the average particle diameter of titanium powder Ti is 45 μ m, the average particle diameter of silicon powder Si is 45 μ m, The average particle size of the aluminum powder Al is 45 μm, and the average particle size of the titanium carbide powder TiC is 38 μm; the weighed titanium powder Ti, silicon powder Si, aluminum powder Al and titanium carbide powder TiC are mixed together to form a mixture A; Put the mixture A in the planetary ball mill, measure absolute ethanol according to the mass of mixture A, add 1ml of absolute ethanol per g of mixture A, add the measured absolute ethanol into the planetary ball mill as a medium, and turn on the planetary ball mill. Type ball mill, ball milled at a rate of 250r / min for 6h to obtain mixture B; take out mixture B obtained after ball milling, place mixture...

Embodiment 2

[0055] Mole ratio is n Ti :n Si :n Al :n TiC =1:1.5:0.2:2 Take titanium powder Ti, silicon powder Si, aluminum powder Al and titanium carbide powder TiC respectively, wherein, the average particle diameter of titanium powder Ti is 58 μ m, the average particle diameter of silicon powder Si is 58 μ m, The average particle size of the aluminum powder Al dopant is 58 μm, and the average particle size of the titanium carbide powder TiC is 45 μm; the weighed titanium powder Ti, silicon powder Si, aluminum powder Al and titanium carbide powder TiC are mixed together to form a mixture A The prepared mixture A is put into the planetary ball mill, measure dehydrated alcohol by the quality of mixture A, add the dehydrated alcohol of 1.2ml of the mixture A of every g, add the dehydrated alcohol measured as medium into the planetary ball mill , turn on the planetary ball mill, and ball mill at a rate of 300r / min for 8 hours to obtain mixture B; take out the mixture B obtained after ball...

Embodiment 3

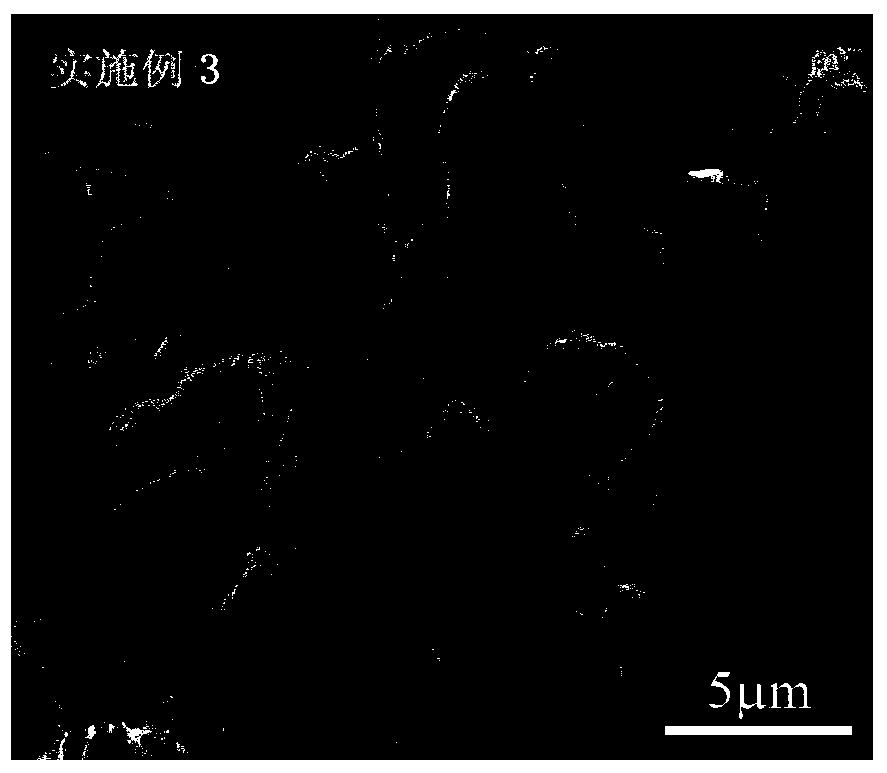

[0060] Mole ratio is n Ti :n Si :n Al :n TiC =3:2:0.6:4 Weigh titanium powder Ti, silicon powder Si, aluminum powder Al and titanium carbide powder TiC respectively, wherein, the average particle diameter of titanium powder Ti is 62 μm, and the average particle diameter of silicon powder Si is 62 μm, The average particle size of the aluminum powder Al dopant is 62 μm, and the average particle size of the titanium carbide powder TiC is 58 μm; the weighed titanium powder Ti, silicon powder Si, aluminum powder Al and titanium carbide powder TiC are mixed together to form a mixture A The mixture A prepared is put into the planetary ball mill, and dehydrated alcohol is taken by the quality of the mixture A, the dehydrated alcohol of every g of the mixture A is added 1.3ml, and the dehydrated alcohol that is measured is added into the planetary ball mill as a medium , turn on the planetary ball mill, and ball mill at a speed of 320r / min for 10 hours to obtain a mixture B; take ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com