Environment-friendly curing agent with ultra low free TDI (toluene diisocyanate) content and preparation method thereof

An environmentally friendly curing agent and content technology, which is applied in the field of ultra-low free TDI content of an environmentally friendly curing agent and its preparation, can solve the problems of expensive and complicated molecular distillation equipment, does not meet national standards, and has a fast reaction speed, and achieves easy construction and operation. , Reduce production safety accidents and solve the effect of heavy brush marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

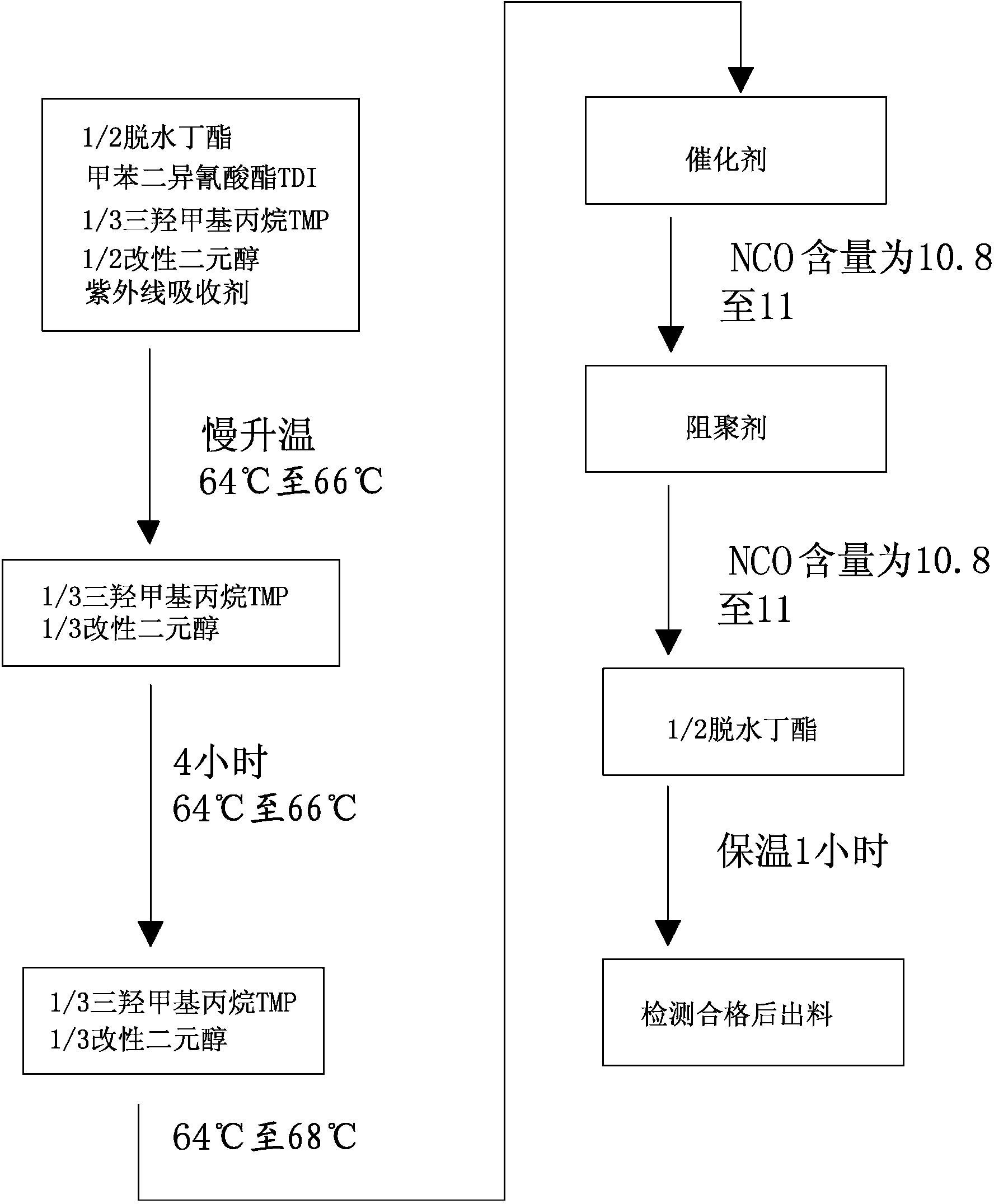

[0045] The following examples are illustrative, and are only used to explain the present invention, but cannot be construed as limiting the present invention.

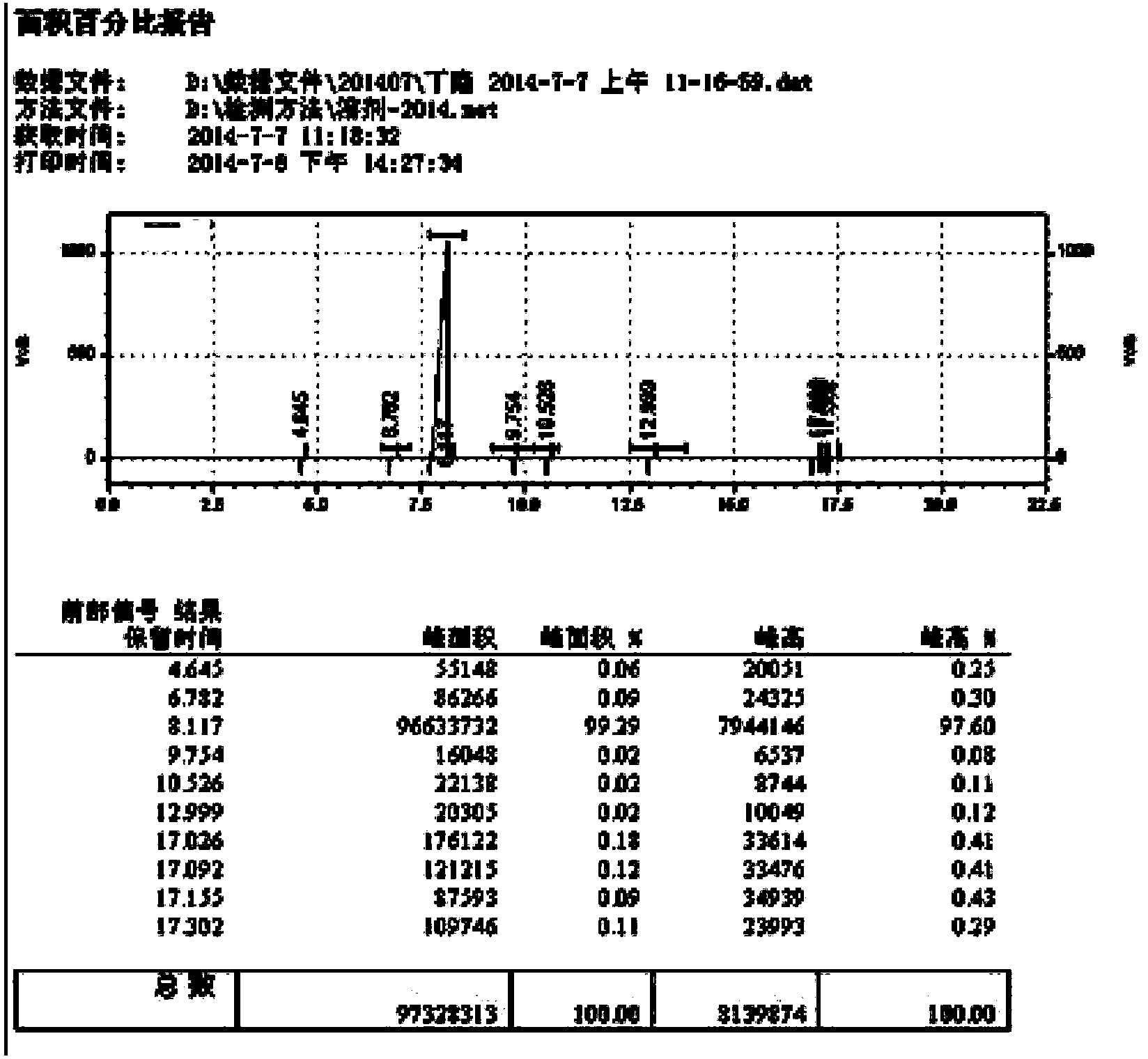

[0046] According to a kind of environment-friendly solidifying agent of ultra-low free TDI content of the present invention, it is characterized in that: by composition and the weight percentage of each composition is:

[0047] Toluene diisocyanate TDI 35%~45%

[0048] Trimethylolpropane TMP 9%~12%

[0049] Modified diol 3%~4%

[0050] Catalyst 0.05%~0.06%

[0051] Inhibitor 0.05%~0.06%

[0052] UV absorber 0.1%~0.2%

[0053] Dehydrating agent 0.2%~0.3%

[0054] Butyl ester 38%~52%.

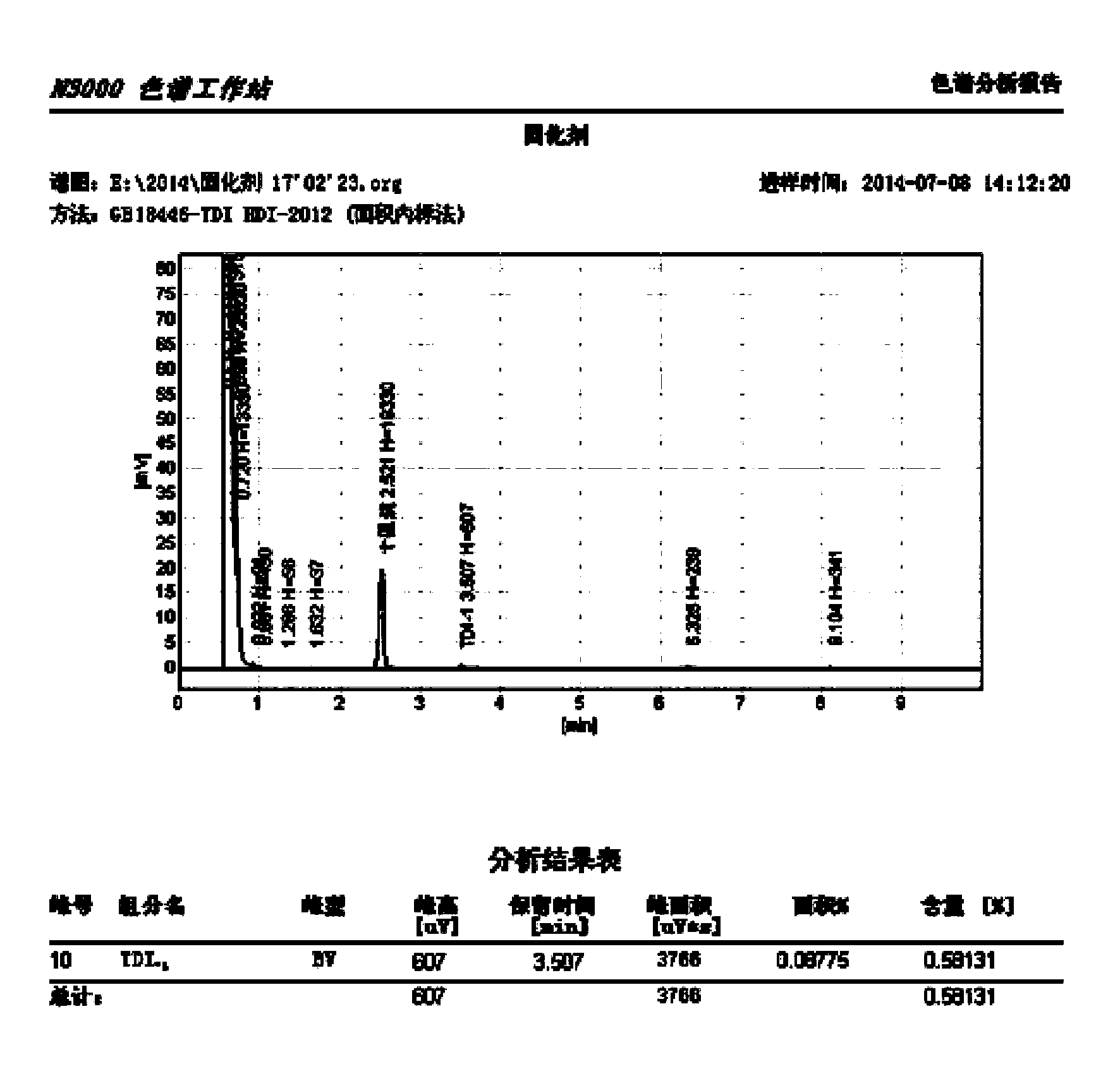

[0055] The TDI-TMP curing agent was synthesized by chemical synthesis at a ratio of NCO / OH of 3.1:1 to 3.2:1, in which three composite catalysts of tertiary amine, alkylphosphorus and zinc naphthenate were used for catalysis to promote the free toluene di The rapid reduction of isocyanate TDI content makes the product have the charac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com