Environment-friendly flame-retardant polyurethane imitation wood for building materials and preparation method thereof

An environmentally friendly, polyurethane technology, applied in the field of combined polyethers, can solve the problems of affecting production efficiency, slow trimerization, and high odor, and achieve the effects of low production cost, fine and uniform cells, and reduced system viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

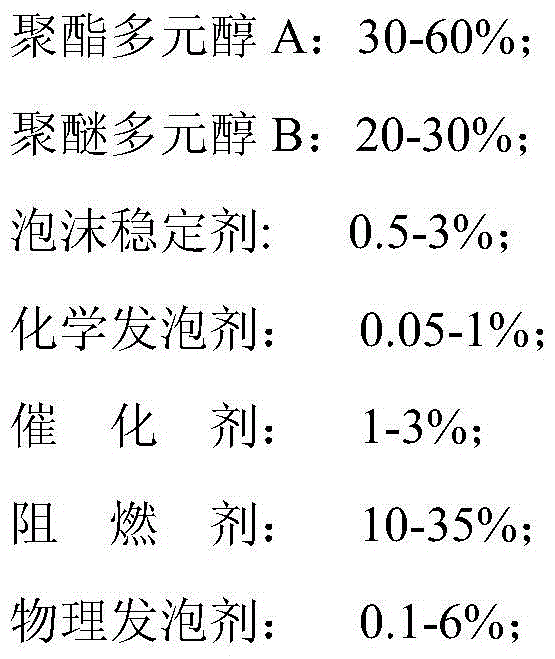

Method used

Image

Examples

Embodiment 1

[0032] Prepare 100Kg of component A, weigh respectively: polyester polyol A CF-6925 (Jiangsu Fusheng): 35Kg, polyether polyol B EDS-5083 (Jiangsu Changneng): 30Kg, catalyst PC8 (N,N dimethyl Cyclohexylamine): 0.3Kg, JXP508 (Air Chemical): 2Kg, JXP509 (Air Chemical): 0.2Kg, deionized water: 0.5Kg, L6952: 1.5Kg, TCPP [tris(2-chloropropyl) phosphate] : 20Kg, TEP (triethyl phosphate): 10Kg, HFC-365mfc (1,1,1,3,3-pentafluorobutane): 0.48Kg, HFC-134a (1,1,1,2-tetra Fluoroethane): 0.02Kg.

[0033] Add the weighed polyester polyol A, polyether polyol B, foam stabilizer, chemical foaming agent, catalyst, flame retardant, and physical foaming agent into the reaction kettle in turn, and stir for 1 hour at normal temperature. That is to get component A, take it out from the reaction kettle and store it in barrels.

[0034] Mix components A and B according to the weight ratio of A:B=100:160 to make environmentally friendly flame-retardant polyurethane imitation wood for building material...

Embodiment 2

[0036] Prepare 100Kg of component A, weigh separately: polyester polyol A CF-6925 (Jiangsu Fusheng): 45Kg, polyether polyol B EDS-5083 (Jiangsu Changneng): 23Kg, catalyst PC8 (N,N dimethyl Cyclohexylamine): 0.3Kg, JXP508 (Air Chemical): 1Kg, JXP509 (Air Chemical): 0.2Kg, Water: 0.1Kg, L6952: 1.8Kg, TCPP[tris(2-chloropropyl) phosphate]: 20Kg , TEP (triethyl phosphate): 5Kg, HFC-365mfc (1,1,1,3,3-pentafluorobutane): 3.5Kg, HFC-134a (1,1,1,2-tetrafluoroethane alkane): 0.1Kg.

[0037] Add the weighed polyester polyol A, polyether polyol B, foam stabilizer, chemical foaming agent, catalyst, flame retardant, physical foaming agent into the reaction kettle in turn, and stir at normal temperature for 1.5 hours, That is to get component A, take it out from the reaction kettle and store it in barrels.

[0038] Mix components A and B according to the weight ratio of A:B=100:160 to make environmentally friendly flame-retardant polyurethane imitation wood for building materials. B is dip...

Embodiment 3

[0040] Prepare 100Kg of component A, weigh separately: polyester polyol A CF-6925 (Jiangsu Fusheng): 55Kg, polyether polyol B EDS-5083 (Jiangsu Changneng): 20Kg, catalyst PC8 (N,N dimethyl Cyclohexylamine): 0.45Kg, JXP508 (Air Chemical): 1.2Kg, JXP509 (Air Chemical): 0.3Kg, Water: 0.05Kg, L6952: 2Kg, TCPP[tris(2-chloropropyl) phosphate]: 10Kg , TEP (triethyl phosphate): 6Kg, HFC-365mfc (1,1,1,3,3-pentafluorobutane): 4.8Kg, HFC-134a (1,1,1,2-tetrafluoroethane Alkane): 0.2Kg.

[0041] Add the weighed polyester polyol A, polyether polyol B, foam stabilizer, chemical foaming agent, catalyst, flame retardant, physical foaming agent into the reaction kettle in turn, and stir at normal temperature for 1.2 hours, That is to get component A, take it out from the reaction kettle and store it in barrels.

[0042] Mix components A and B according to the weight ratio of A:B=100:160 to make environmentally friendly flame-retardant polyurethane imitation wood for building materials, and te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com