Modification recovery method for waste plastic

A recycling method and waste plastic technology, applied in the field of waste plastic recycling, can solve the problems of unsuitability for industrialized production, complex procedures, damage to plastic mechanical properties, etc., and achieve the effects of facilitating industrialized production, improving recycling performance, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

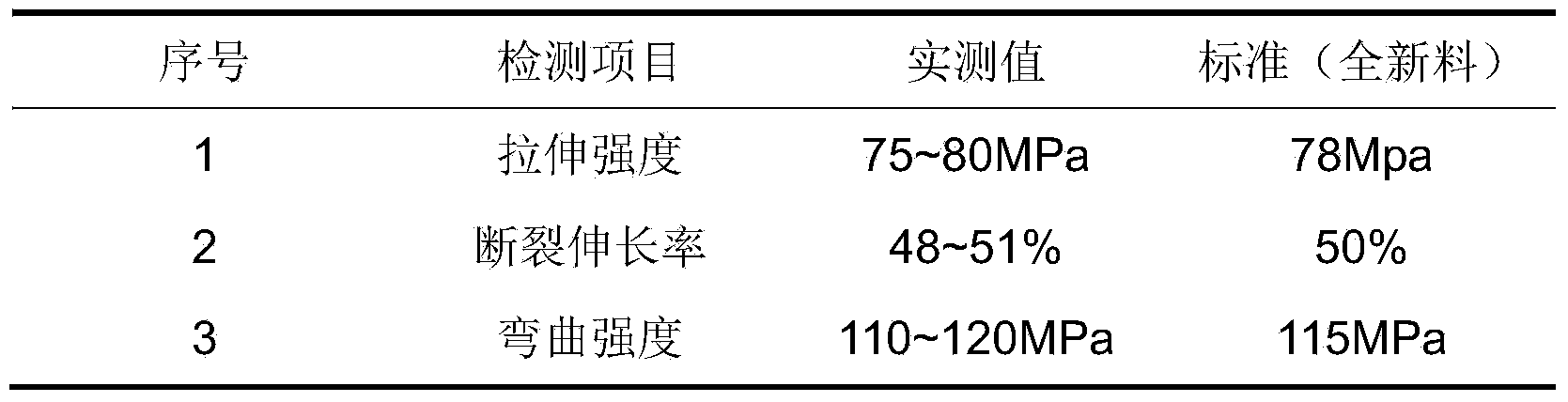

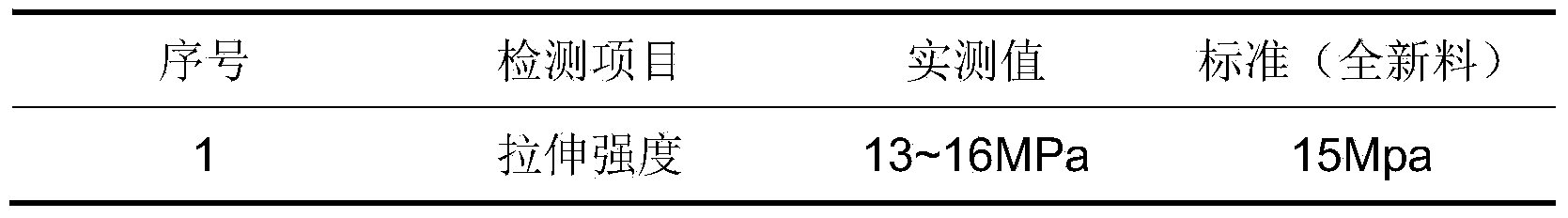

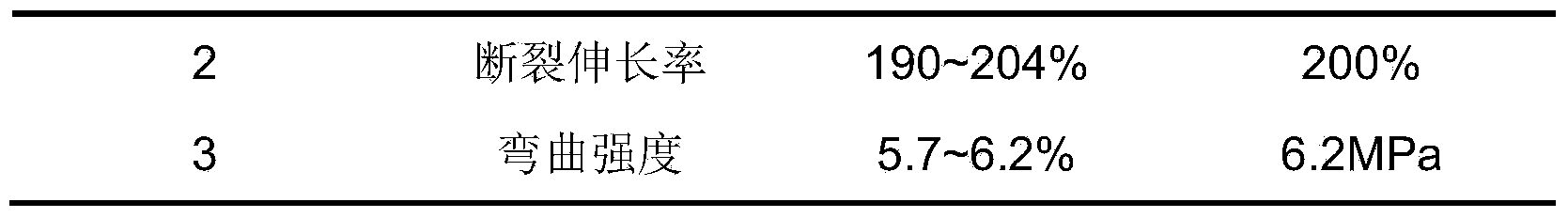

Embodiment 1

[0015] The recycled waste PET plastics are crushed, cleaned, dehydrated and dried to remove water to obtain waste plastic raw materials, mixed with improver at a weight ratio of 95:5, and then added to a granulator for blending and granulation to obtain masterbatches.

[0016] Ratio of modifier components: 0.5% 2,5-dimethyl-2,5-di-tert-butylperoxyhexane, 2-(2'-hydroxy-5'-methylphenyl)benzotriazepam oxazole 2%, dioctyl phthalate 2%, polyethylene wax 0.2%, 2,2-methylenebis(4-methyl-6-butylphenol) 2%.

Embodiment 2

[0018] The recycled waste PET plastics are crushed, cleaned, dehydrated and dried to remove water to obtain waste plastic raw materials, mixed with improver at a weight ratio of 98:2, and then added to a granulator for blending and granulation to obtain masterbatches.

[0019] Ratio of modifier components: 0.5% 2,5-dimethyl-2,5-di-tert-butylperoxyhexane, 2-(2'-hydroxy-5'-methylphenyl)benzotriazepam oxazole 2%, dioctyl phthalate 2%, polyethylene wax 0.2%, 2,2-methylenebis(4-methyl-6-butylphenol) 2%.

Embodiment 3

[0021] The recycled waste PET plastics are crushed, cleaned, dehydrated and dried to remove water to obtain waste plastic raw materials, mixed with improver at a weight ratio of 95:5, and then added to a granulator for blending and granulation to obtain masterbatches.

[0022] Ratio of modifier components: 2,5-dimethyl-2,5-di-tert-butylperoxyhexane 1%, 2-(2'-hydroxy-5'-methylphenyl)benzotriazepam oxazole 5%, dioctyl phthalate 5%, polyethylene wax 0.5%, 2,2-methylene bis(4-methyl-6-butylphenol) 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com