Heat-resistant nano-silver conductive paint and manufacturing process thereof

A conductive coating and nano-silver technology, applied in conductive coatings, coatings, etc., can solve the problems of high resistivity, high temperature melting deformation, heat resistance and other problems of conductive films, and achieve improved conductivity, less additives, and low resistivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

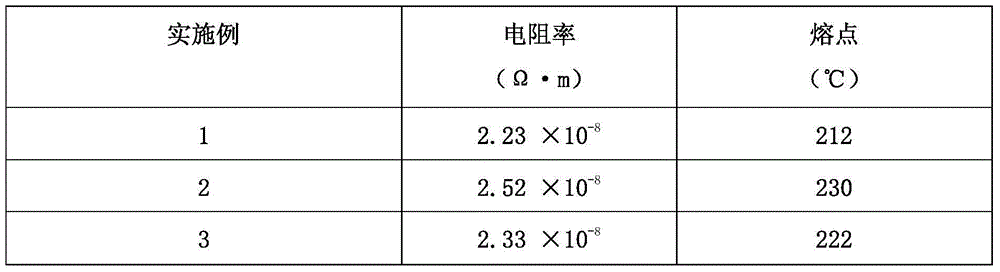

Examples

Embodiment 1

[0033] Heat-resistant nano-silver conductive coating of the present invention, described heat-resistant nano-silver conductive coating is made up of the following components by weight:

[0034] Type III polypropylene 18 parts,

[0035] Heat-resistant polyethylene 10 parts,

[0036] 0.8 parts of dicumyl peroxide,

[0037] 20 parts of viscosity modifier,

[0038] 7 parts tackifying resin,

[0039] 3 parts graphite powder,

[0040] Silver powder 2 parts,

[0041] 10 parts of silver nanowire dispersion;

[0042] Described nano-silver wire dispersion liquid is made up of the following components by weight:

[0043] Silver nitrate 2 parts,

[0044] 10 parts of glycerol,

[0045] 1 part corrosive agent,

[0046] 3 parts polyvinylpyrrolidone,

[0047] Dispersant 0.5 part,

[0048] 4 parts of water.

Embodiment 2

[0050] Heat-resistant nano-silver conductive coating of the present invention, described heat-resistant nano-silver conductive coating is made up of the following components by weight:

[0051] Type III polypropylene 19 parts,

[0052] Heat-resistant polyethylene 12 parts,

[0053] 0.9 parts of dicumyl peroxide,

[0054] Viscosity regulator 25 parts,

[0055] 7.5 parts of tackifying resin,

[0056] 4 parts graphite powder,

[0057] Silver powder 2.5 parts,

[0058] 13 parts of silver nanowire dispersion;

[0059] Described nano-silver wire dispersion liquid is made up of the following components by weight:

[0060] 5 parts of silver nitrate,

[0061] 13 parts of glycerol,

[0062] 2 parts of etchant,

[0063] 4 parts polyvinylpyrrolidone,

[0064] Dispersant 0.8 part,

[0065] 5 parts of water.

Embodiment 3

[0067] Heat-resistant nano-silver conductive coating of the present invention, described heat-resistant nano-silver conductive coating is made up of the following components by weight:

[0068] Type III polypropylene 20 parts,

[0069] Heat-resistant polyethylene 13 parts,

[0070] 1 part dicumyl peroxide,

[0071] 30 parts of viscosity modifier,

[0072] 8 parts tackifying resin,

[0073] 5 parts graphite powder,

[0074] Silver powder 3 parts,

[0075] 16 parts of silver nanowire dispersion;

[0076] Described nano-silver wire dispersion liquid is made up of the following components by weight:

[0077] 6 parts of silver nitrate,

[0078] 15 parts of glycerol,

[0079] 3 parts of corrosive agent,

[0080] 6 parts of polyvinylpyrrolidone,

[0081] 1 part of dispersant,

[0082] 6 parts of water.

[0083] The steps of the manufacturing process of heat-resistant nano-silver conductive paint are as follows:

[0084] Step 1. Put silver nitrate, glycerin, and polyvinyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com