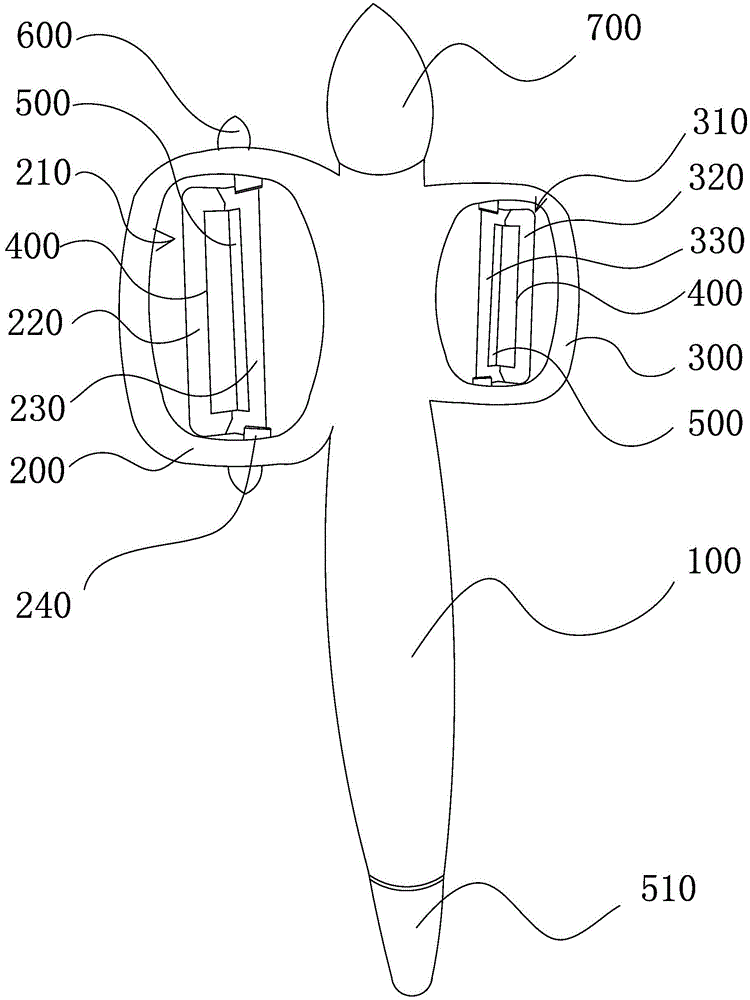

Multifunctional peeler

A peeler and multifunctional technology, which is applied in the field of multifunctional peelers, can solve the problems of narrow use range of peelers, inconvenient use of users, and reduced use efficiency, etc., and achieve good insulation, prolong service life, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

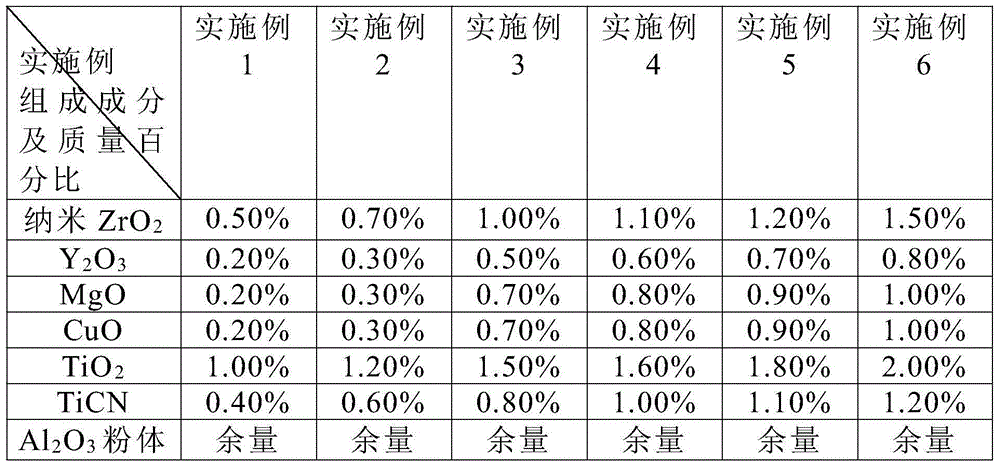

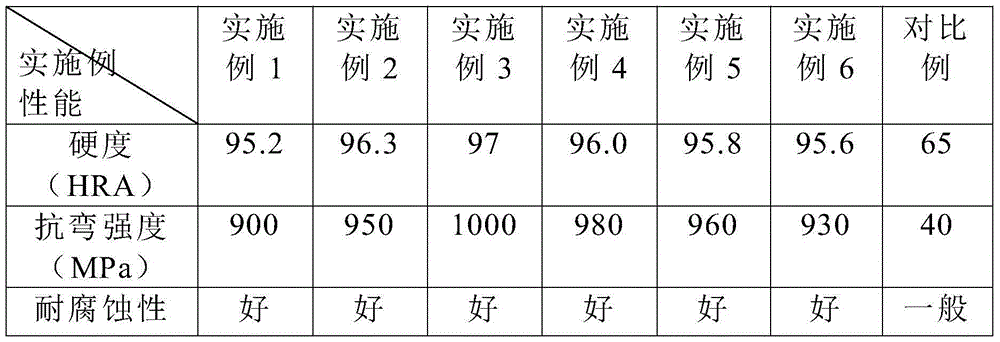

Embodiment 1

[0040] According to the composition and mass percentage of the alumina ceramics used in the blade described in Table 1, Example 1, batching and mixing are carried out, and after mixing, wet ball milling is carried out for 60 hours. The ball milling medium liquid is absolute ethanol, and then dried under vacuum, wherein the drying temperature The temperature is 80℃, and the drying time is 8h;

[0041] Add a molding binder such as polyethylene glycol to the above-mentioned dried material and granulate it, and then use 130MPa / m 2 The pressure is pressurized for 1min to form the blade body;

[0042] The above-mentioned blade green body was subjected to vacuum hot-pressing sintering at 1200°C and 20 MPa for 1 hour, and then the finished blade was obtained through surface treatment.

Embodiment 2

[0044] According to the composition and mass percentage of the alumina ceramics used in the blade described in Table 1, Example 2, batching and mixing are carried out, and after mixing, wet ball milling is carried out for 65 hours. The ball milling medium liquid is absolute ethanol, and then dried under vacuum, wherein the drying temperature The temperature is 85℃, and the drying time is 8h;

[0045] Add a molding binder such as wax emulsion to the above-mentioned dried material and granulate it, and then use 140MPa / m 2 The pressure is pressed for 1.5min to form the blade body;

[0046] The above-mentioned blade green body was subjected to vacuum hot pressing and sintering at 1300° C. and 20 MPa for 1.2 hours, and then the finished blade was obtained through surface treatment.

Embodiment 3

[0048] According to the composition and mass percentage of the alumina ceramics used in the blade described in Table 1, Example 3, batching and mixing are carried out, and after mixing, wet ball milling is carried out for 75 hours. The ball milling medium liquid is absolute ethanol, and then dried under vacuum, wherein the drying temperature 100℃, drying time is 9h;

[0049] Add a molding binder such as polyethylene glycol to the above-mentioned dried material and granulate it, and then use 150MPa / m 2 The pressure is pressurized for 2 minutes to form the blade blank;

[0050] The above-mentioned blade body was vacuum hot-pressed and sintered at 1300° C. and 23 MPa for 1.3 hours, and then the finished blade was obtained through surface treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com