CO2 catalytic conversion device and method

A technology for catalytic conversion, CO2, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of low reaction selectivity and conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

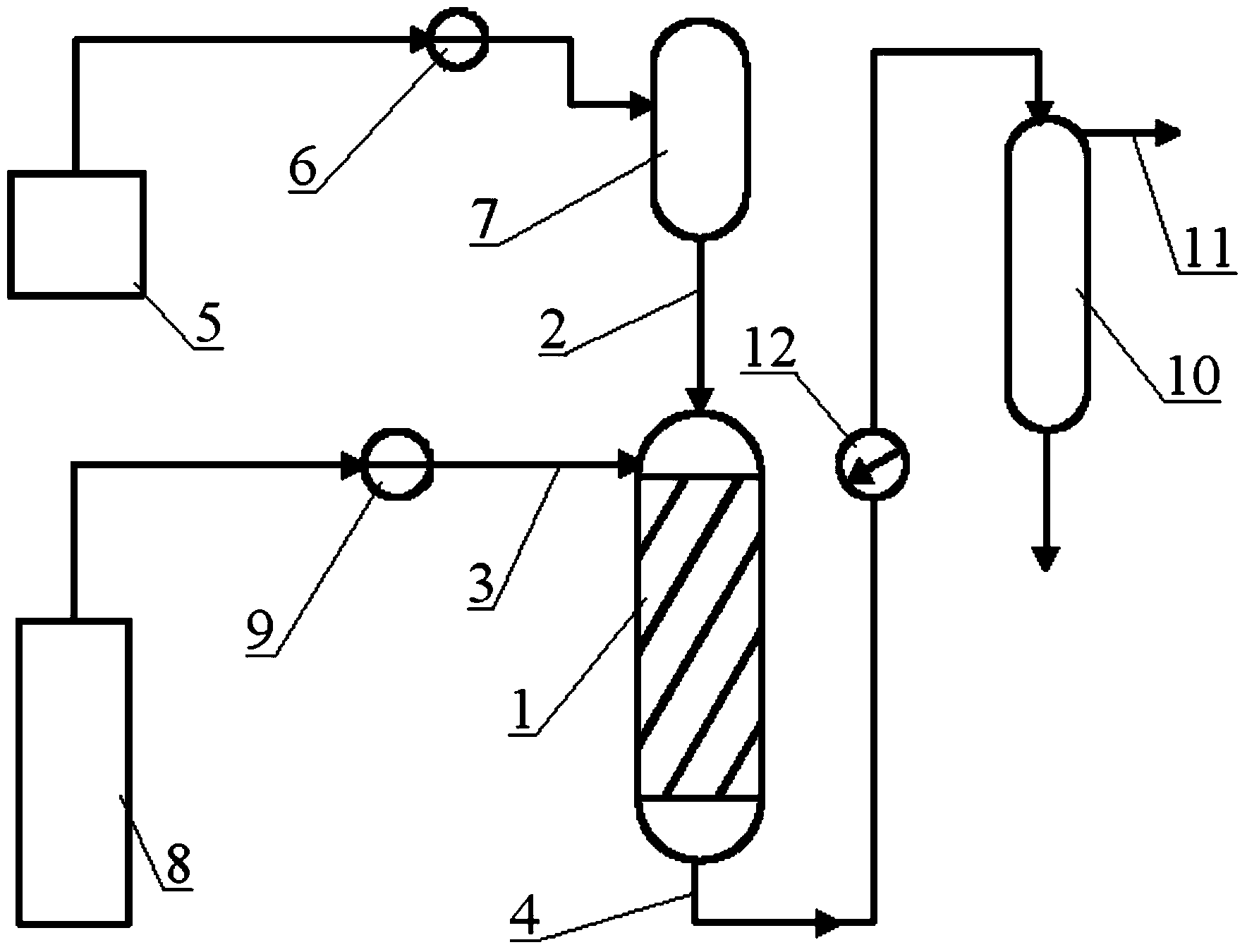

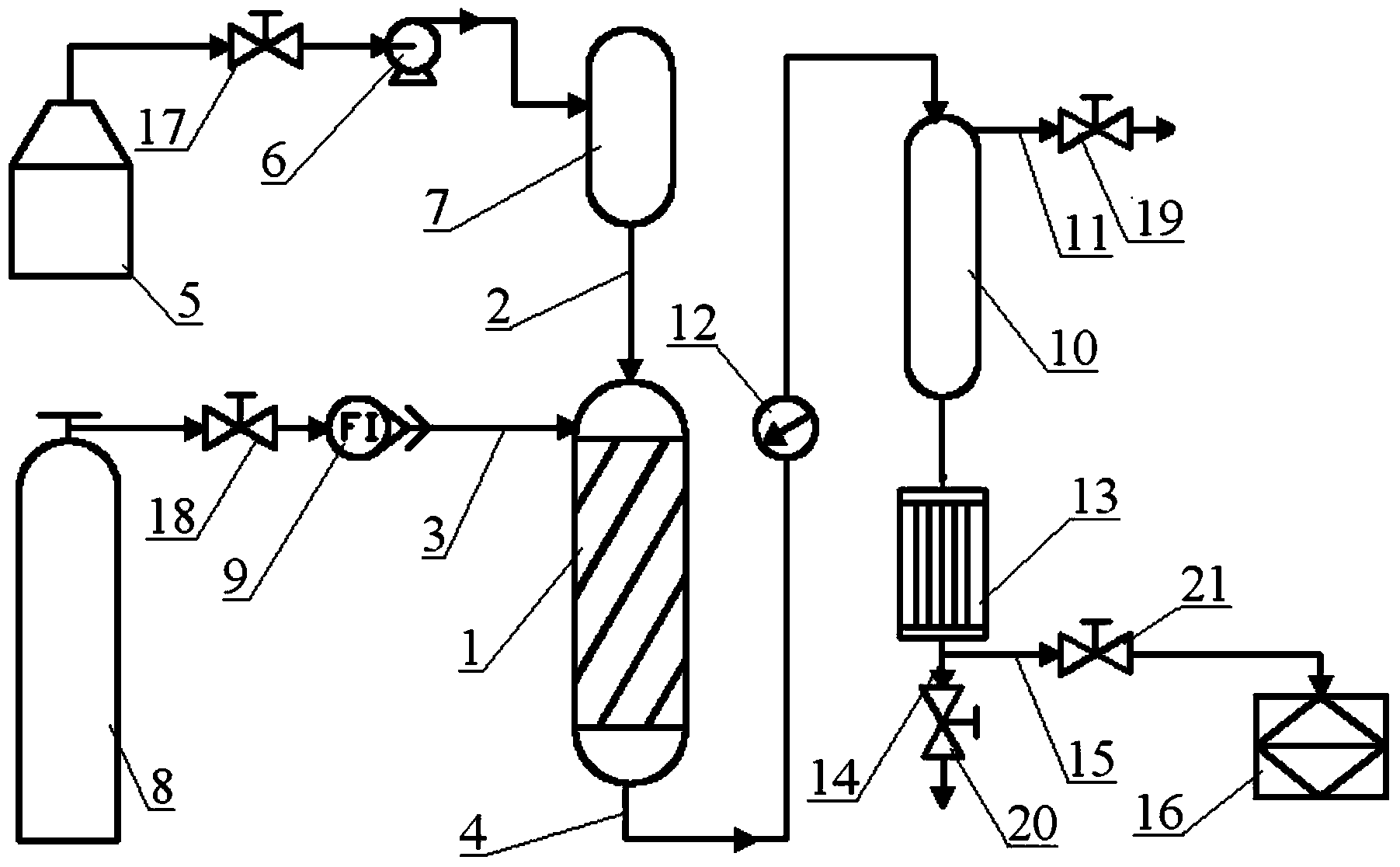

Method used

Image

Examples

preparation example Construction

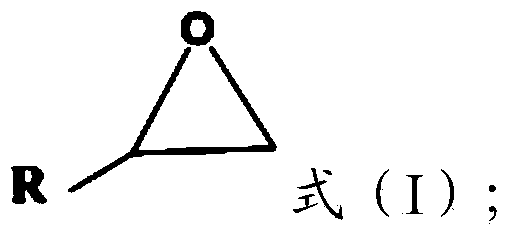

[0065] In the present invention, the catalyst for the catalytic reaction is preferably an activated carbon-supported ionic liquid catalyst; the activated carbon-supported ionic liquid catalyst includes a supported halogen anion-containing ionic liquid catalyst and a supported non-halogen anion-containing ionic liquid catalyst. In the present invention, the preparation method of the supported ionic liquid catalyst containing halogen anion preferably comprises the following steps:

[0066] The active carbon carrier is oxidized, silylated, imidazolized and halogenated sequentially to obtain a supported ionic liquid catalyst containing halogen anions.

[0067] In the present invention, the activated carbon support is sequentially oxidized, silanized, imidazolized and halogenated. The activated carbon carrier is preferably coconut shell activated carbon. The present invention has no special limitation on the source of the activated carbon carrier, and the above-mentioned commercia...

Embodiment 1

[0088] Preparation of supported halogen anion-containing ionic liquid catalyst Bmim / Br:

[0089] (1) Under the conditions of 105°C and nitrogen protection, reflux 3g of coconut shell activated carbon carrier oxidized by nitric acid and 0.32g of 3-chloropropyltrimethoxysilane in 100mL of toluene for 20h, then wash and filter with absolute ethanol, Vacuum drying at 70°C for 7 hours to obtain a silanized coconut shell activated carbon carrier.

[0090] (2) Under the condition of 105°C, reflux the above-mentioned silanized coconut shell activated carbon carrier and 0.11g imidazole in toluene for 7h, then wash with absolute ethanol, filter, and vacuum dry at 70°C for 7h to obtain imidazolized coconut shell Shell activated carbon carrier.

[0091] (3) At 105°C, 5 g of the imidazolized coconut shell activated carbon support and 0.34 g of brominated n-butane were refluxed in 100 mL of toluene for 4 h to obtain a supported halogen anion-containing ionic liquid catalyst Bmim / Br.

Embodiment 2

[0093] Preparation of supported halogen anion-containing ionic liquid catalyst Bmim-COOH / Br:

[0094] (1) Under the conditions of 105°C and nitrogen protection, reflux 3g of coconut shell activated carbon carrier oxidized by nitric acid and 0.32g of 3-chloropropyltrimethoxysilane in 100mL of toluene for 20h, then wash and filter with absolute ethanol, Vacuum drying at 70°C for 7 hours to obtain a silanized coconut shell activated carbon carrier.

[0095] (2) Under the condition of 105°C, reflux the above-mentioned silanized coconut shell activated carbon carrier and 0.11g imidazole in toluene for 7h, then wash with absolute ethanol, filter, and vacuum dry at 70°C for 7h to obtain imidazolized coconut shell Shell activated carbon carrier.

[0096] (3) At 105°C, 5 g of the imidazolized coconut shell activated carbon support and 0.34 g of bromobutyric acid were refluxed in 100 mL of toluene for 7 h to obtain a supported halogen anion-containing ionic liquid catalyst Bmim-COOH / Br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com