Horizontal device and method for friction-stir welding of circular seam of carrier rocket storage tank assembly

A friction stir, launch vehicle technology, applied in auxiliary devices, welding equipment, welding equipment, etc., to achieve high-efficiency welding, small torque, and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

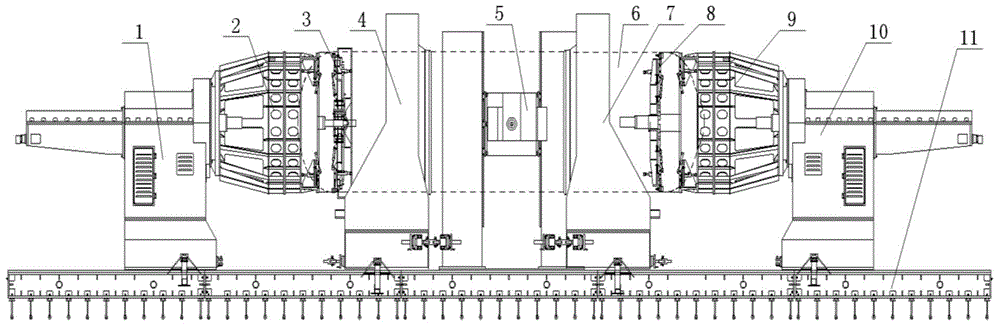

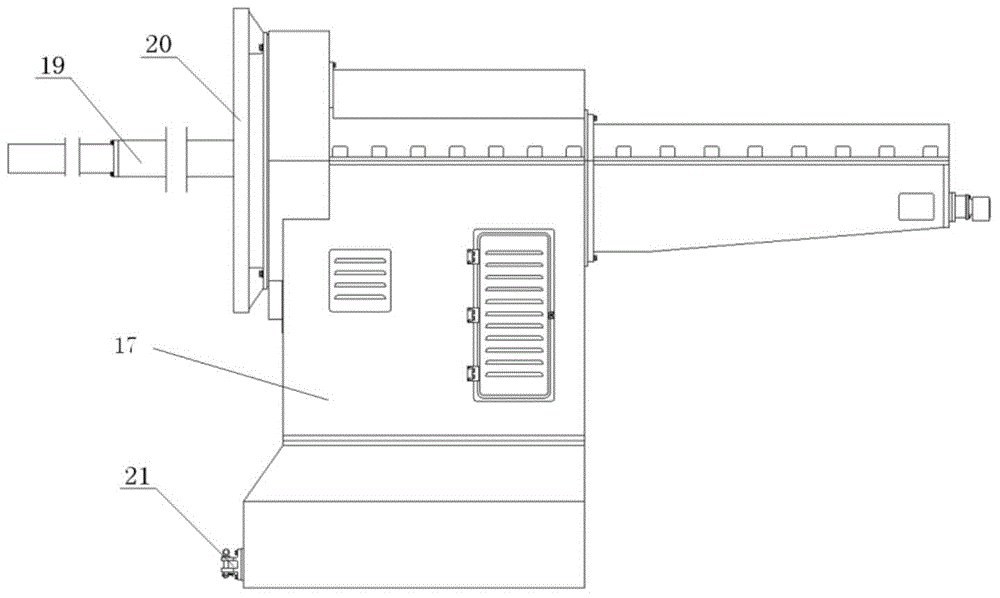

[0027] Such as figure 1 As shown in the present invention, a horizontal device for friction stir welding of a launch vehicle storage tank assembly circular seam, the storage tank 6 is a front short shell, a front bottom, a multi-section barrel section, and a rear The bottom and a rear short shell are welded in sequence. The device includes a bed 11, and the head of the bed 10 and the tail of the bed 1 are arranged at both ends above the bed 11 respectively; Compression mechanism 4 and rear transition ring 2; Inner support mechanism 8, bar system support mechanism 3 are hung on the head of a bed telescopic shaft 19 and the tail of a bed telescopic shaft 25 respectively, and can move horizontally with the telescopic axis.

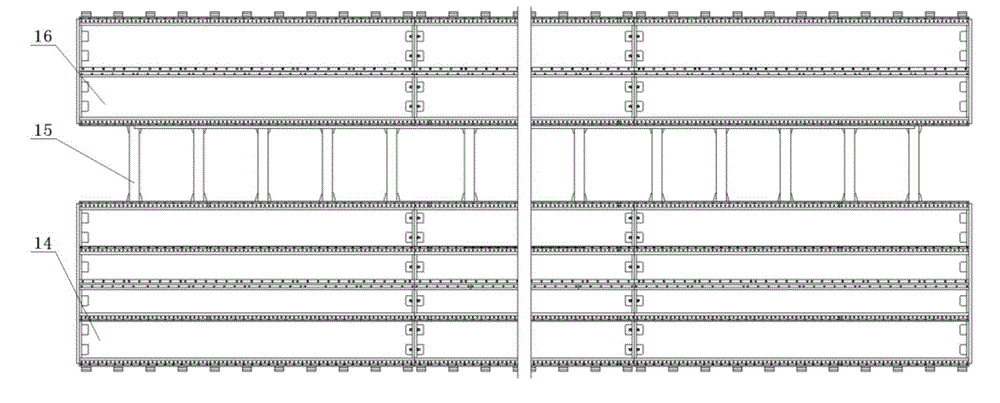

[0028] Such as figure 2 As shown, the bed 11 includes a main bed 14 and an auxiliary bed 16, and the main bed 14 and the auxiliary bed 16 are connected by a number of reinforcing beams 15, which can better eliminate the influence of the stirring friction f...

Embodiment 2

[0035] Adopt the horizontal welding method of the friction stir welding of the circular seam of the general assembly of the launch vehicle storage tank of the horizontal device described in embodiment 1, the described storage tank 6 is composed of 1 front short shell, 1 front bottom, multi-section barrel sections, A rear bottom and a rear short shell are sequentially welded; the welding method includes the following steps:

[0036] (a) Hoist the front short shell and front bottom assembly on the head of the bed 10, connect the front short shell with the front transition ring 9 in quadrants; 2 Connect according to the quadrant; move the right outer positioning and pressing mechanism 7 to the front bottom, position and press the front short shell and the front bottom, move the left outer positioning and pressing mechanism 4 to the first section of the cylinder, position and press Tighten the first barrel section; hoist the inner support mechanism 8 on the telescopic shaft 19 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com