Sandwich structure composite material and preparation method thereof

A composite material and sandwich structure technology, which is applied in the field of resin-based composite material structural parts, sandwich structure composite materials and their preparation, can solve the problems of inability to meet the longitudinal compression load of the vehicle chassis and insufficient lateral pressure performance, and achieve improvement Insufficient lateral pressure performance, high bending rigidity, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Preparation of hollow rectangular tube sandwich structure composite material flat plate

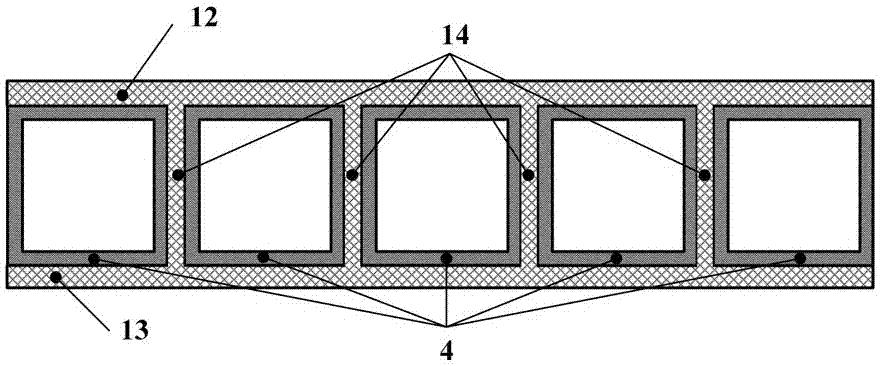

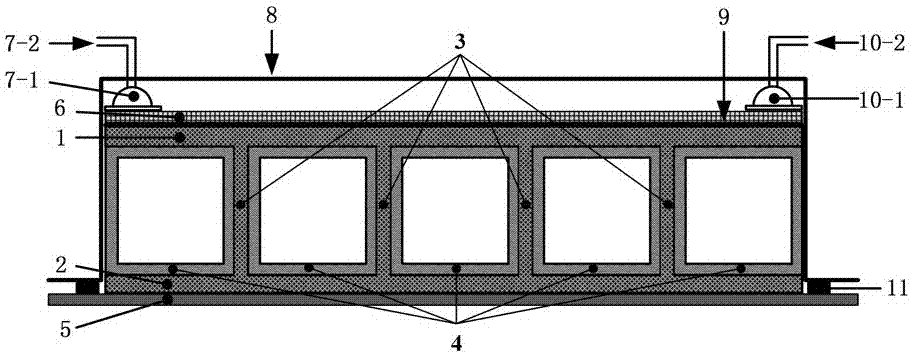

[0036] A sandwich structure composite material of the present invention, such as figure 1 As shown, the sandwich structure composite material includes an upper panel 12, a lower panel 13 and a core layer, the core layer is located between the upper panel 12 and the lower panel 13, the core layer includes 5 hollow rectangular tubes 4, and in the core layer, the hollow The rectangular tubes 4 are arranged parallel to each other (arranged at intervals), and a tube intercalation layer 14 is provided between adjacent hollow rectangular tubes 4 .

[0037] In this embodiment, the hollow rectangular tube 4 is made of unidirectional glass fiber reinforced unsaturated polyester resin-based composite material, the intertube layer 14 is made of glass fiber reinforced epoxy resin composite material, the upper panel 12 and the lower panel 13 Both are made of glass fiber reinforced epo...

Embodiment 2

[0050] Example 2 Preparation of Carbon Fiber Reinforced Hollow Rectangular Tube Sandwich Structure Composite Vehicle Underframe

[0051] A kind of sandwich structure composite material of the present invention (schematic structure can refer to figure 1 ), the sandwich structure composite material includes an upper panel 12, a lower panel 13 and a core layer, the core layer is located between the upper panel 12 and the lower panel 13, the core layer includes 54 hollow rectangular tubes 4, in the core layer, the hollow rectangular tube The tubes 4 are arranged at intervals in a parallel manner, and a tube intercalation layer 14 is provided between adjacent hollow rectangular tubes 4 .

[0052] In this embodiment, the hollow rectangular tube 4 is made of unidirectional carbon fiber reinforced epoxy resin composite material, the intertube layer 14 is made of glass fiber reinforced epoxy resin composite material, and the upper panel 12 and the lower panel 13 are both made of Made ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com