Device and method of melting polysilicon powder by electron beam

An electron beam smelting, polysilicon technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of long smelting time and increased energy consumption of electron beam smelting, shorten the smelting time, save manpower and material resources, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

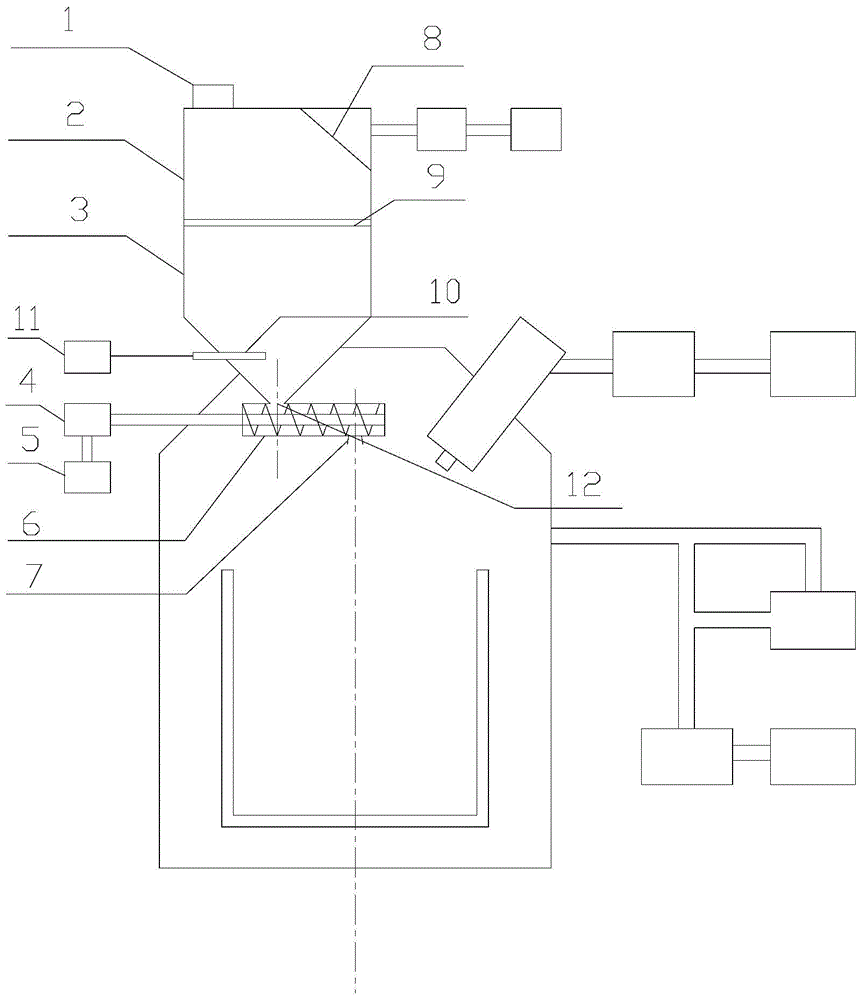

[0026] Such as figure 1 As shown, a device for electron beam smelting polysilicon powder includes a melting chamber, an electron gun and its vacuum system, a melting chamber vacuum system, a crucible and a feeding system, and the feeding system includes a feeding bin 2 and an inlet below it The feeding bin 3, the feeding bin 2 and the feeding bin 3 are isolated by a butterfly valve 9; the bottom of the feeding bin 3 is provided with a feeding port 12 leading into the smelting chamber, and the lower end of the feeding port 12 is connected to a screw feeder 6, and the screw feeder 6 The feeder is connected to the geared motor 4 and the time controller 5, and the speed of the geared motor 4 is controlled by adjusting the time controller 5 to drive the screw feeder 6 to realize feeding at a fixed rate, and the feeding rate can be adjusted. A bulk material opening is provided below the screw feeder, and the diameter of the bulk material opening is 5 mm; the diameter of the cross se...

Embodiment 2

[0035] Such as figure 1As shown, a device for electron beam smelting polysilicon powder includes a melting chamber, an electron gun and its vacuum system, a melting chamber vacuum system, a crucible and a feeding system, and the feeding system includes a feeding bin 2 and an inlet below it The feeding bin 3, the feeding bin 2 and the feeding bin 3 are isolated by a butterfly valve 9; the bottom of the feeding bin 3 is provided with a feeding port 12 leading into the smelting chamber, and the lower end of the feeding port 12 is connected to a screw feeder 6, and the screw feeder 6 The feeder is connected to the geared motor 4 and the time controller 5, and the speed of the geared motor 4 is controlled by adjusting the time controller 5 to drive the screw feeder 6 to realize feeding at a fixed rate, and the feeding rate can be adjusted. A bulk material opening is provided below the screw feeder, and the diameter of the bulk material opening is 20 mm; the diameter of the cross se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com