Modified glutinous-rice mortar for masonry and preparation method thereof

A glutinous rice mortar and modification technology, applied in the field of building materials, can solve the problems of complex preparation process, low strength, large shrinkage, etc., and achieve the effects of simplifying the preparation process, reducing the shrinkage rate, and reducing the water demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of glutinous rice mortar

[0034] Weigh 100 parts with a purity of 95% and an apparent density of 0.72g / cm 3 , The specific surface area is 10.68m 2 / g of calcium hydroxide, 75 parts of calcium carbonate with a particle size of 0.6-1 mm, 225 parts of calcium carbonate with a particle size of 0.3-0.6 mm, 225 parts of calcium carbonate with a particle size of 0.18-0.3 mm, 5 parts of amylopectin The content is 92%, the apparent density is 0.17g / cm 3 Pregelatinized glutinous rice flour, 1 part of French Eisen C-SP polycarboxylate superplasticizer and 1 part of hydroxypropyl methylcellulose with a viscosity of 150,000mPa·s, mixed the dry material at a stirring speed of 500rpm for 5min, and added 95 After dividing the water, stir at a speed of 1500 rpm for 8 minutes until the mortar is evenly mixed to obtain glutinous rice mortar.

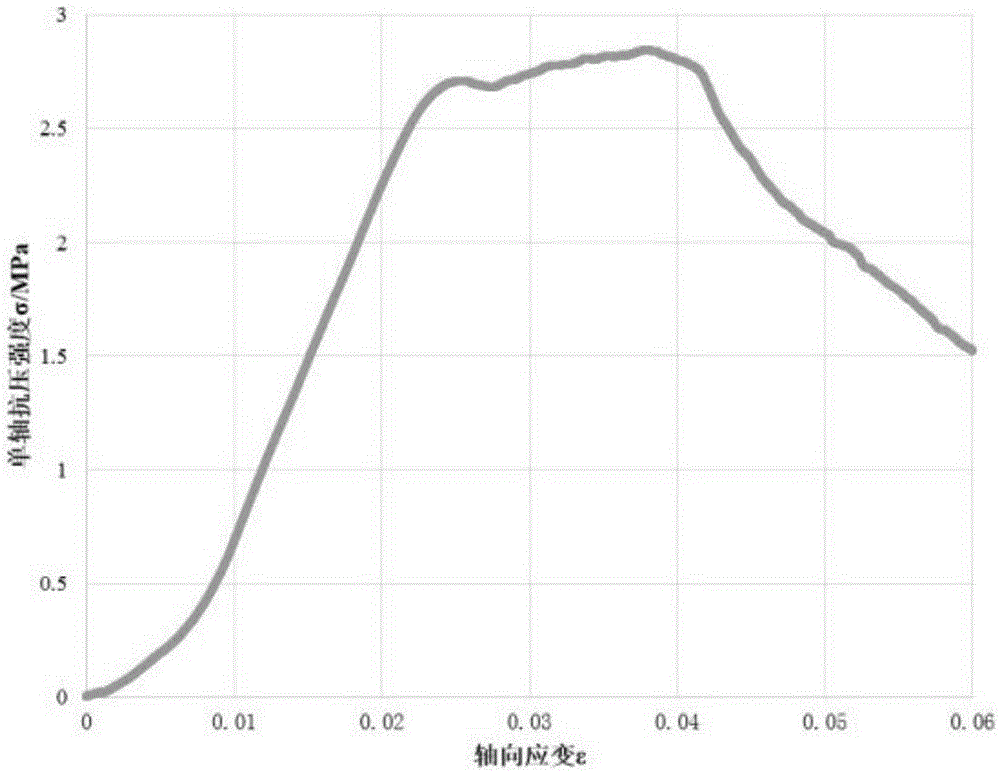

[0035] 2. Inspection of the performance of glutinous rice mortar

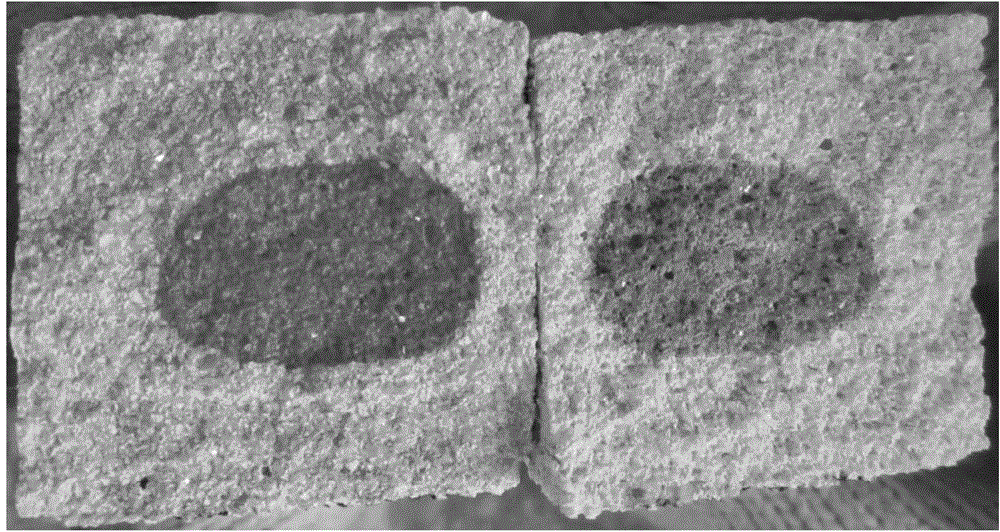

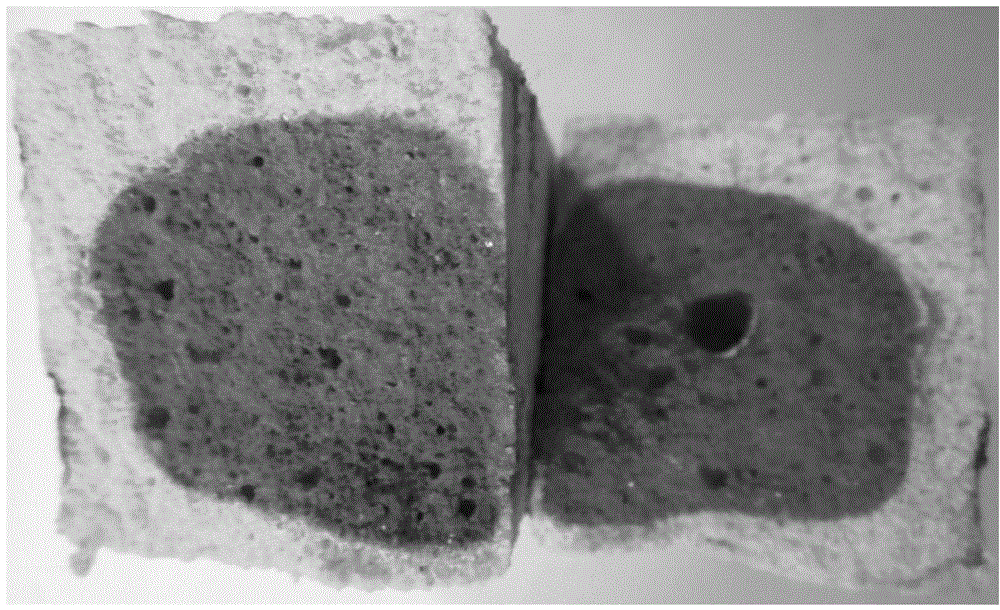

[0036] Pour the mortar into the test mold, and after castin...

Embodiment 2

[0042] 1. Preparation of glutinous rice mortar

[0043] Weigh 100 parts with a purity of 95% and an apparent density of 0.72g / cm 3 , The specific surface area is 10.68m 2 / g of calcium hydroxide, 75 parts of calcium carbonate with a particle size of 0.6 to 1 mm, 225 parts of calcium carbonate with a particle size of 0.3 to 0.6 mm, 225 parts of calcium carbonate with a particle size of 0.18 to 0.3 mm, and 75 parts with a particle size of Calcium carbonate of 0.125~0.18mm, 5 parts of amylopectin content of 92%, apparent density of 0.17g / cm 3 Pre-gelatinized glutinous rice flour, 1 part of French Eisen C-SP polycarboxylate superplasticizer and 1 part of hydroxypropyl methylcellulose with a viscosity of 150,000mPa·s, mixed the dry material at a stirring speed of 500rpm for 5min, and added 106 After dividing the water, stir at a speed of 1500 rpm for 8 minutes until the mortar is evenly mixed to obtain glutinous rice mortar.

[0044] 2. Inspection of the performance of glutinous...

Embodiment 3

[0051] 1. Preparation of glutinous rice mortar

[0052] Weigh 100 parts with a purity of 95% and an apparent density of 0.72g / cm 3 , The specific surface area is 10.68m 2 / g of calcium hydroxide, 37.5 parts of calcium carbonate with a particle size of 0.6 to 1 mm, 112.5 parts of calcium carbonate with a particle size of 0.3 to 0.6 mm, 112.5 parts of calcium carbonate with a particle size of 0.18 to 0.3 mm, and 37.5 parts with a particle size of Calcium carbonate of 0.125~0.18mm, 5 parts of amylopectin content of 92%, apparent density of 0.17g / cm 3 Pre-gelatinized glutinous rice flour, 1 part of French Eisen C-SP polycarboxylate superplasticizer and 1 part of hydroxypropyl methylcellulose with a viscosity of 150,000mPa·s, mixed the dry material at a stirring speed of 500rpm for 5min, and added 81.5 After dividing the water, stir at a speed of 1500 rpm for 8 minutes until the mortar is evenly mixed to obtain glutinous rice mortar.

[0053] 2. Inspection of the performance of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com