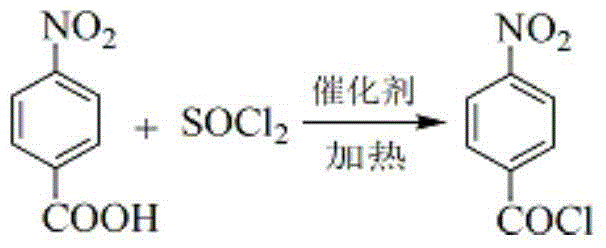

Method and equipment for preparing paranitrobenzoyl chloride

A technology of nitrobenzoyl chloride and p-nitrobenzoic acid, which is applied in the field of preparation of p-nitrobenzoyl chloride, can solve the problems of solvent residue, increased production cost and equipment investment, difficult handling of phosphorus oxychloride, etc., and achieves The production cycle is short, the distillation purification time is shortened, and the product yield is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

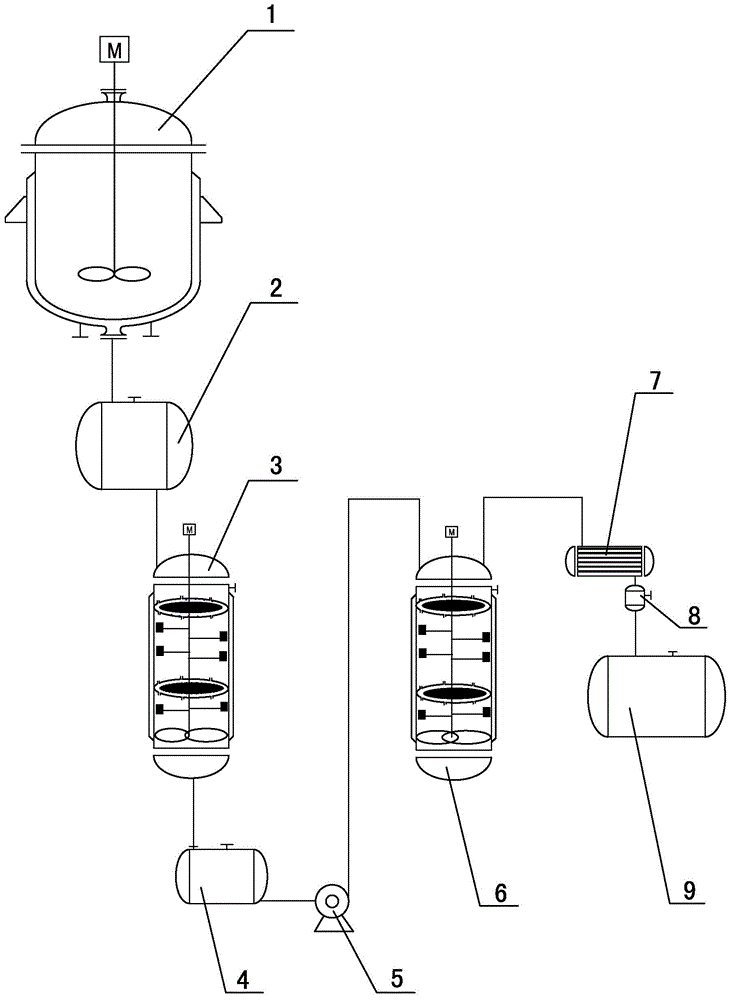

[0033] (1) Put 500Kg of p-nitrobenzoic acid and 1250Kg of thionyl chloride into the reaction kettle, add 2.5Kg of N,N-dimethylformamide, and carry out the reaction at 90°C until no gas comes out. Atmospheric distillation, then distillation under 600mmHg until no thionyl chloride flows out to obtain the p-nitrobenzoyl chloride crude product, and put into the overhead tank;

[0034] (2) Turn on the primary thin film evaporator, and heat up to 100°C; the secondary thin film evaporator, and heat up to 175°C;

[0035] (3) Adjust the vacuum of the first-stage thin film evaporator to be 720mmHg, start feeding, and uniformly add the crude product to the first-stage thin-film evaporator according to a certain sampling speed; the discharge enters the crude product storage tank, and the material in the crude product storage tank Enter into the secondary thin film evaporator through the magnetic pump;

[0036] (4) Adjust the vacuum degree of the secondary thin-film evaporator to be 730mm...

Embodiment 2

[0038] (1) Put 500Kg of p-nitrobenzoic acid and 1500Kg of thionyl chloride into the reactor, add 0.5Kg of N,N-dimethylformamide, and carry out the reaction at 90°C until no gas comes out. Atmospheric distillation, and then distilling under vacuum at 610mmHg until no thionyl chloride flows out, obtains the crude product of p-nitrobenzoyl chloride, and puts it into the overhead tank;

[0039] (2) Turn on the primary thin film evaporator, and heat up to 120°C; the secondary thin film evaporator, and heat up to 165°C;

[0040] (3) Adjust the vacuum of the first-stage thin film evaporator to 700mmHg, start feeding, and uniformly add the crude product to the first-stage thin-film evaporator according to a certain sampling speed; the discharge enters the crude product storage tank, and the material in the crude product storage tank Enter into the secondary thin film evaporator through the magnetic pump;

[0041] (4) Adjust the vacuum degree of the secondary thin-film evaporator to b...

Embodiment 3

[0043] (1) Put 500Kg of p-nitrobenzoic acid and 1750Kg of thionyl chloride into the reaction kettle, add 5Kg of N,N-dimethylformamide, and react at 90°C until no gas comes out. pressure distillation, and then distilled under 630mmHg until no thionyl chloride flows out to obtain the p-nitrobenzoyl chloride crude product, and put it into the overhead tank;

[0044] (2) Turn on the primary thin film evaporator, and heat up to 130°C; the secondary thin film evaporator, and heat up to 155°C;

[0045] (3) Adjust the vacuum degree of the first-level thin film evaporator to be 660mmHg, start feeding, and add the crude product to the first-level thin film evaporator evenly by a certain sampling speed; the discharge enters the crude product storage tank, and the crude product storage tank The material enters the secondary thin film evaporator through the magnetic pump;

[0046] (4) Adjust the vacuum degree of the secondary thin-film evaporator to be 750mmHg, start feeding, and the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com