Preparation method for disperse red 343:1 dye

A technology of disperse red and dyes, which is applied in the direction of azo dyes, organic dyes, monoazo dyes, etc., which can solve the problems of environmental hazards and difficult waste water treatment, and reduce the possibility of waste water discharge and harm to people and the environment , High light fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

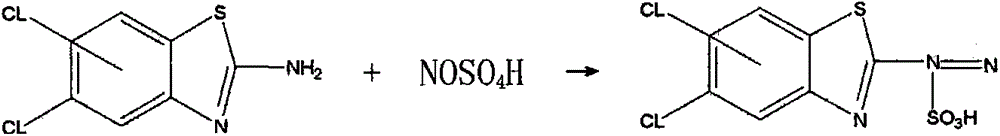

[0024] (1) In a 1000ml three-necked flask with a stirring device, add 18 grams of water, add 36 grams of sulfuric acid at 25 ° C and stir, and cool down with salt water; dropwise add 15 grams of nitrosyl sulfuric acid when the temperature drops to -2 ° C, After dropping, 10 g of 2-amino-5,6-dichlorobenzothiazole was added at 2°C, stirred at 8°C for 2 hours, and left to stand to obtain the diazonium salt.

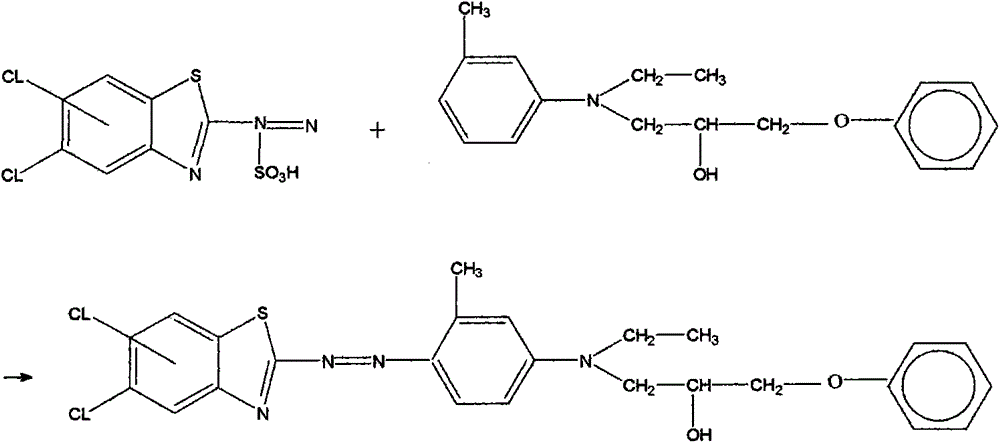

[0025] (2) In a 1000ml beaker, add 50 grams of water, 20 grams of glacial acetic acid, 0.2 grams of sulfamic acid, and add 0.2 grams of N-ethyl-N-benzoyloxyethyl m-toluidine (content 60%) 18 g, add ice and cool down to 0°C, press into the above diazonium salt, and slowly couple.

[0026] (3) After the coupling is completed, stir for 2 hours, add water to raise the temperature to 65° C., and keep the temperature for 3 hours.

[0027] (4) Press filtration, wash with water until neutral, obtain 34.5 grams of disperse red 343:1 dye filter cake, the yield is 92.5%.

[0028] (5)...

Embodiment 2

[0030] (1) In a 1000ml three-necked flask with a stirring device, add 20 grams of water, add 40 grams of sulfuric acid at 30°C and stir, and cool down with brine; when the temperature drops to 0°C, add 18 grams of nitrosyl sulfuric acid dropwise, After that, 20 g of 2-amino-5,6-dichlorobenzothiazole was added at 5°C, stirred at 9°C for 2 hours, and left to stand to obtain the diazonium salt.

[0031] (2) In a 1000ml beaker, add 55 grams of water, 25 grams of glacial acetic acid, 0.4 grams of sulfamic acid, and add 0.4 grams of N-ethyl-N-benzoyloxyethyl m-toluidine (content 60%) 22 g, add ice and cool down to 2°C, press into the above diazonium salt, and slowly couple.

[0032] (3) After the coupling is completed, stir for 2 hours, add water to raise the temperature to 68° C., and keep the temperature for 3 hours.

[0033] (4) Press filtration, wash with water until neutral, obtain 39.3 grams of disperse red 343:1 dye filter cake, yield 93.1%.

[0034] (5) Take 20 grams of dy...

Embodiment 3

[0036] (1) In a 1000ml three-necked flask with a stirring device, add 22 grams of water, add 44 grams of sulfuric acid at 35°C and stir, and cool down with brine; when the temperature drops to 4°C, add 20 grams of nitrosyl sulfuric acid dropwise, After that, 30 g of 2-amino-5,6-dichlorobenzothiazole was added at 10° C., stirred at 10° C. for 2 hours, and left to stand to obtain the diazonium salt.

[0037] (2) In a 1000ml beaker, add 60 grams of water, 30 grams of glacial acetic acid, 0.6 grams of sulfamic acid, and add 0.6 grams of N-ethyl-N-benzoyloxyethyl m-toluidine (content 60%) 26 g, add ice and cool down to 5°C, press into the above diazonium salt, and slowly couple.

[0038] (3) After the coupling is completed, stir for 2 hours, add water to raise the temperature to 70° C., and keep the temperature for 3 hours.

[0039] (4) Press filtration, wash with water until neutral, obtain 37.5 grams of disperse red 343:1 dye filter cake, yield 92.8%.

[0040] (5) Take 20 grams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com