A method of pressurized production of ammonia caramel color

An ammonia caramel and process technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of raising production costs, frequent ammonia additions, and complicated production operations, and reduce the overall cost of products. , Improve product market competitiveness and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

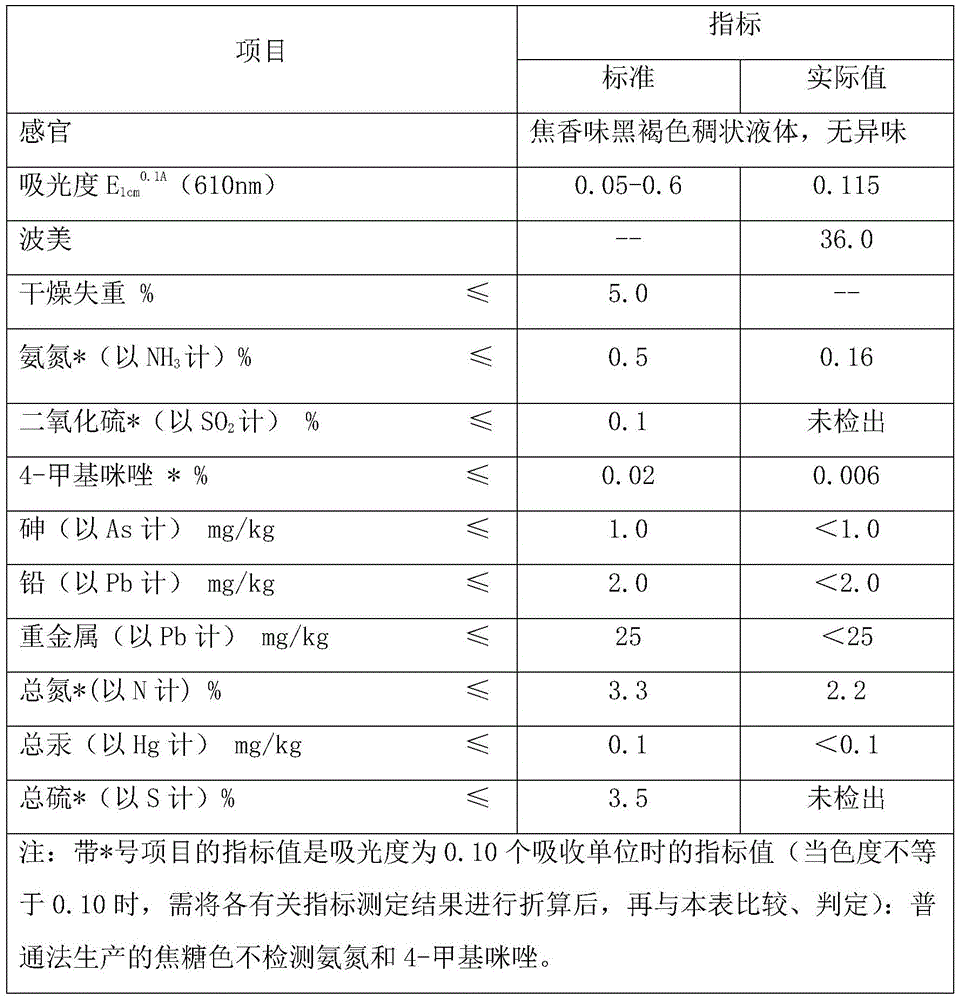

Embodiment 1

[0030] Production of 36Be, 30000EBC ammonia caramel color.

[0031] Estimate: Estimate the dry basis of the ingredients needed for the raw material based on the caramel product Baume. Considering that some water will be produced during the caramel polycondensation reaction, it is estimated that 75% of the dry basis of the raw material ingredients is more appropriate.

[0032] Dosing: Measure 6000kg of starch syrup with a DE value of 97% and a dry basis of 70% into the reaction tank, start stirring, heat up and concentrate. The temperature of the sugar solution rose from 31°C to 115°C, and the dry basis content of the sugar solution was 75% by sampling. Turn off the steam and cool for 48 minutes, and the temperature of the liquid sugar drops to 72°C.

[0033] Ammonia addition: Close the reaction tank, stir, and add ammonia directly into the sugar solution. The amount of ammonia added is 3% of the mass of raw materials, that is, 180kg of liquid ammonia needs to be added, the a...

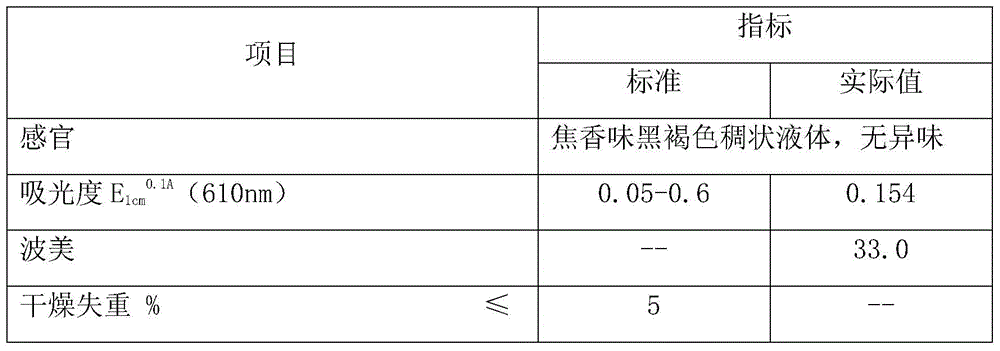

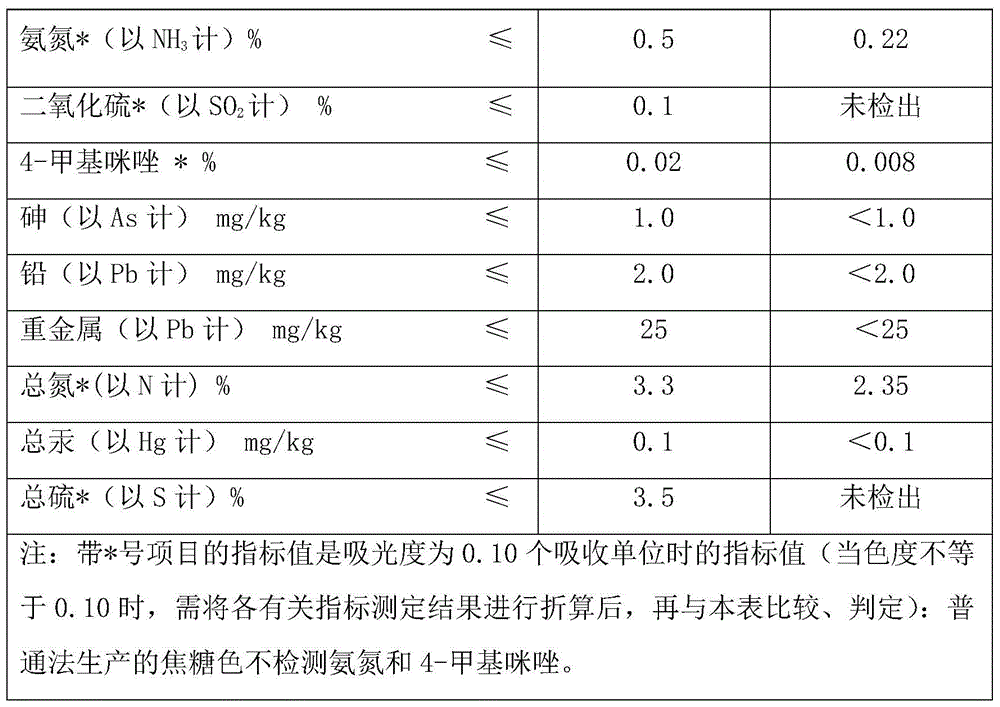

Embodiment 2

[0042] Production of 33Be, 40000EBC ammonia caramel color.

[0043] Estimate: Estimate the dry basis of the ingredients needed for the raw material based on the caramel product Baume. Considering that some water will be produced during the caramel polycondensation reaction, it is estimated that 74% of the dry basis of the raw material ingredients is more appropriate.

[0044]Dosing: Measure 6000kg of starch syrup with a DE value of 98% and a dry basis of 68% into the reaction tank, start stirring, heat up and concentrate. The temperature of the sugar solution rose from 29°C to 113°C, and the dry basis of the sugar solution was 74% by sampling. Turn off the steam and cool for 45 minutes, and the temperature of the liquid sugar drops to 70°C.

[0045] Ammonia addition: Close the reaction tank, stir, and add ammonia directly into the sugar solution. The amount of ammonia added is 5% of the mass of the raw material, that is, 420kg of liquid ammonia is required, the ammonia addit...

Embodiment 3

[0055] In order to verify whether the pressurized method saves ammonia consumption more than the normal pressure method, the production of 36Be and 30000EBC ammonia caramel color is still taken as an example, but the ammonia addition and reaction are all carried out under normal pressure.

[0056] Dosing: Measure 6000kg of starch syrup with a DE value of 97% and a dry basis of 70% into the reaction tank. Because it is designed for normal pressure reaction, it does not need to be concentrated, and it is more convenient to add ammonia.

[0057] Ammonia addition: Start stirring, add ammonia directly into the sugar solution, the amount of ammonia added is 3% of the raw material mass, that is, 180kg of liquid ammonia needs to be added, the ammonia addition speed is 3.0kg / min, and the ammonia addition time is 60 minutes. The temperature in the reaction tank rises slowly from 39°C to 50°C. After the ammonia addition is completed, disconnect the ammonia addition connection and close th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com