Pulse micro displacement sensor and displacement measuring method thereof

A micro-displacement sensor and pulse technology, applied in the field of sensors, can solve the problems of difficult to achieve precision, low curvature of curve, small change of light intensity displacement, etc., and achieve the effect of easy processing, light weight and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

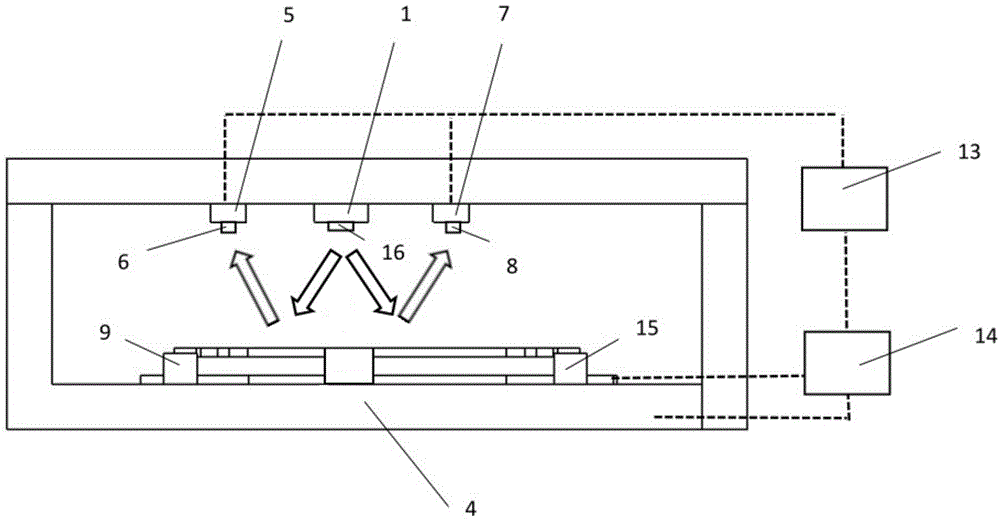

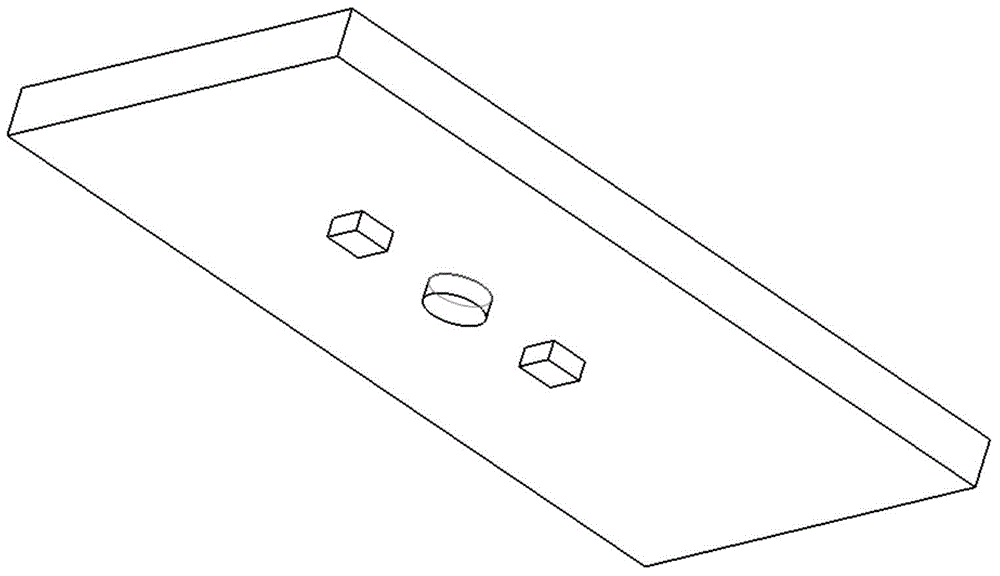

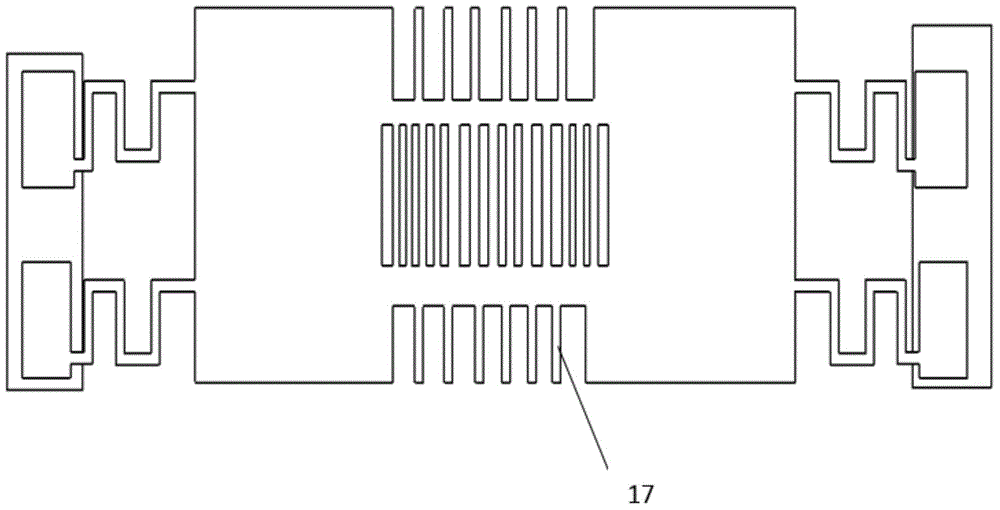

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] When the TE polarized 1530nm infrared light source is irradiated vertically on the sub-wavelength grating, it will propagate in the form of evanescent waves on the surface of the grating. The present invention is based on a special case of Wood's anomaly, that is, when the interval between the two layers of gratings is accurately controlled at the wavelength level of 1 / 5 (300-400nm interval), the parameters such as the period and duty cycle of the gratings are adjusted to make the reflected light The intensity has a pulse-like change with respect to the displacement distance. When the two gratings are very close in the vertical direction, the light will oscillate between the two gratings, the light will pass from one grating to the other through the evanescent field, and the evanescent wave of the other grating will also pass through the evanescent field Coupli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com