Nozzle throat section water cooling structure

A nozzle and throat technology, applied in the field of hypersonic low-density wind tunnel, can solve the problems of inability to improve the structural strength of the inner wall of the nozzle, messy equipment layout, and water leakage of pipe joints, and achieve good cooling effect, convenient replacement and maintenance, The effect of avoiding water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

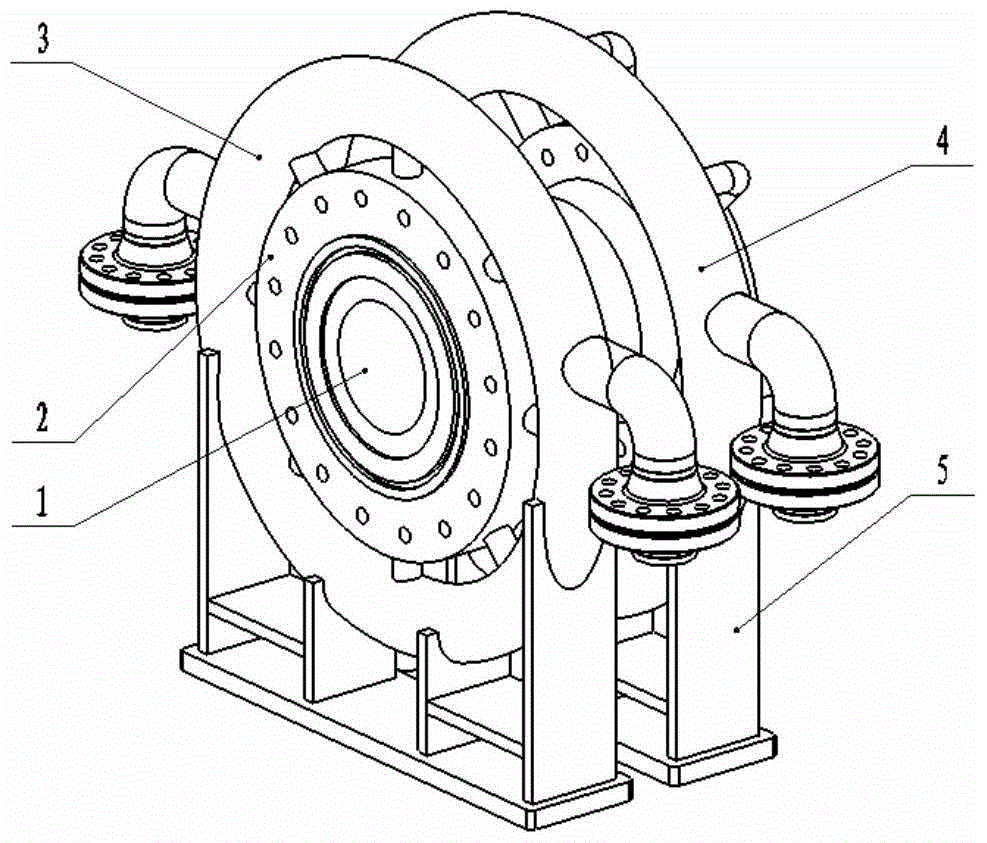

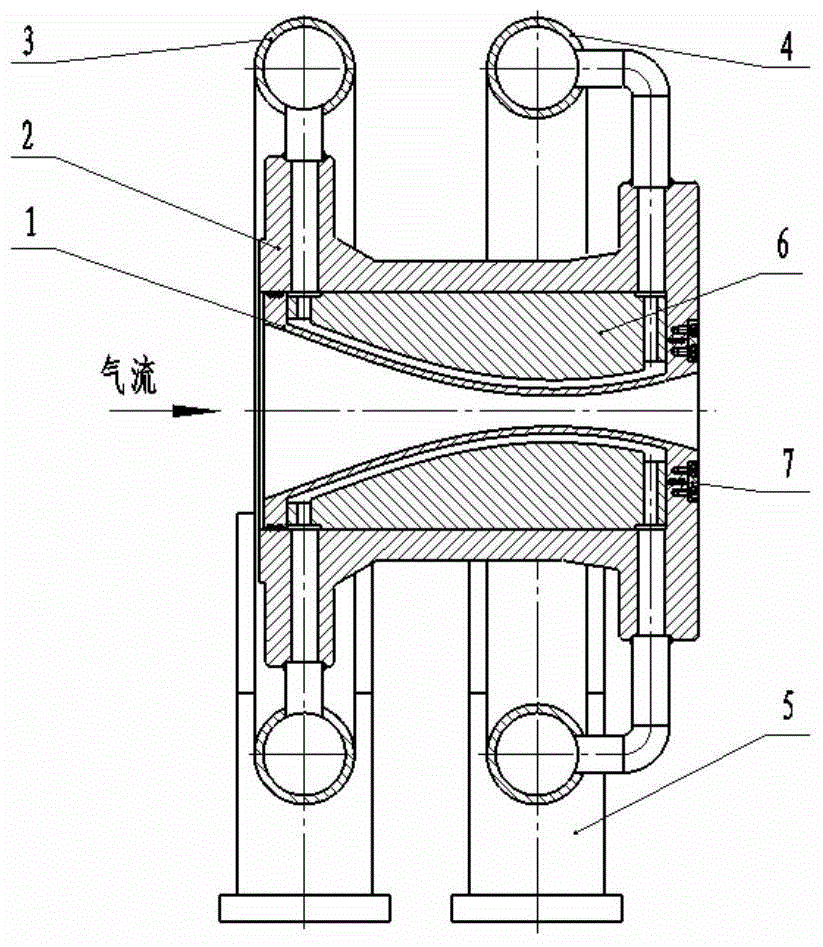

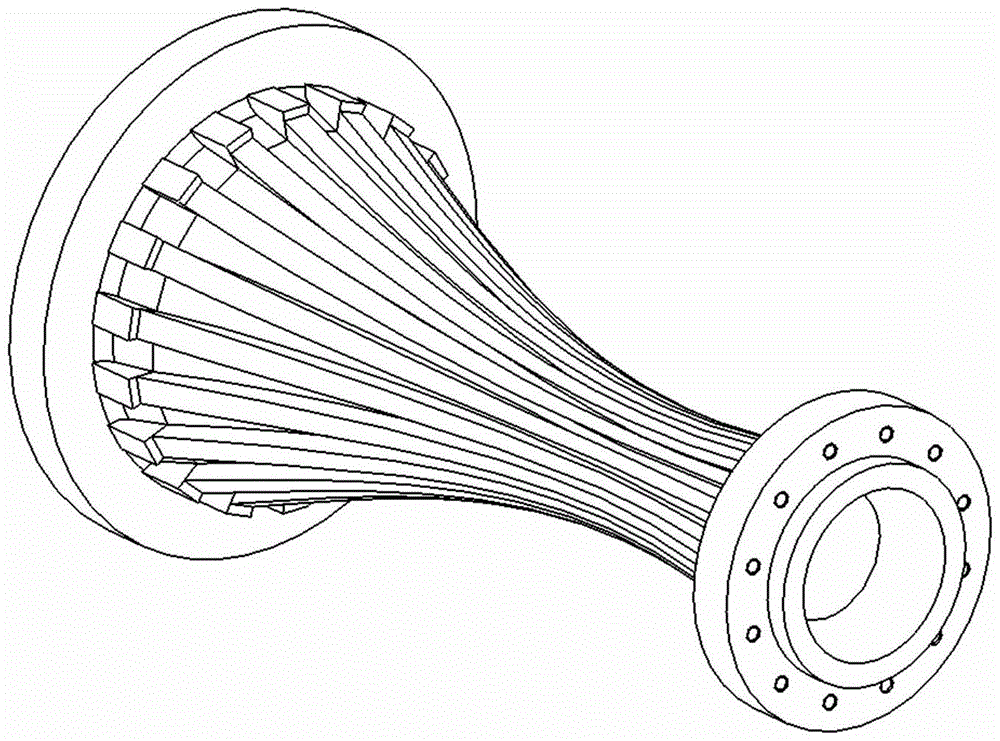

[0017] Such as figure 1 , 2 As shown, the water-cooling structure of the nozzle throat section of the hypersonic low-density wind tunnel includes the inner wall of the nozzle 1, the outer shell 2, the cooling water inlet water collection ring 3, the cooling water outlet water collection ring 4, the small bracket 5, and the clamp block 6, and retaining ring 7 forms. The outer surface of the inner wall 1 of the nozzle is longitudinally grooved to form a cooling water channel; the clamping block 6 is two semicircular bodies matching the shape of the inner wall 1 of the nozzle and the outer shell 2, and the inner surface of the clamping block 6 is a profile curve. The outer surface is a cylindrical surface, and two clamping blocks 6 are combined and installed in the throat section of the nozzle; the rear end of the inner wall 1 of the nozzle along the airflow direction and the outer casing 2 are fixed by a retaining ring 7, and the other end can be properly stretched under high t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com