Photoelectric device manufacturing system with online detection function

A technology for optoelectronic devices and preparation systems, which is applied in the manufacturing/processing of organic semiconductor devices, electric solid state devices, semiconductor/solid state device manufacturing, etc. performance of organic semiconductor materials research and other issues, to achieve the effect of improving accuracy and realizing real-time measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The content of the invention of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

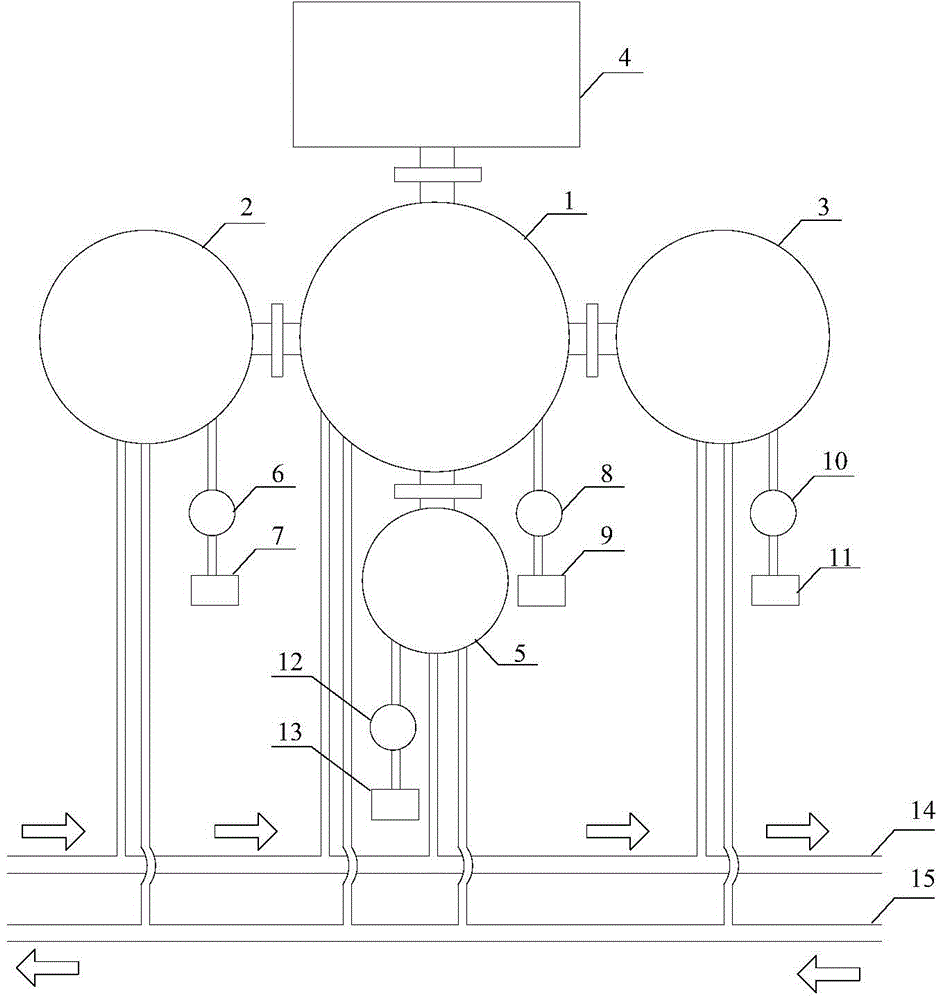

[0033] Such as figure 1 As shown, the optoelectronic device preparation system with online detection function provided in this embodiment includes a conversion chamber 1 , a first evaporation chamber 2 , a second evaporation chamber 3 , a glove box 4 and a detection chamber 5 . The conversion chamber 1 communicates with the first evaporation chamber 2 , the second evaporation chamber 3 , the glove box 4 and the detection chamber 5 respectively through a vacuum isolation valve.

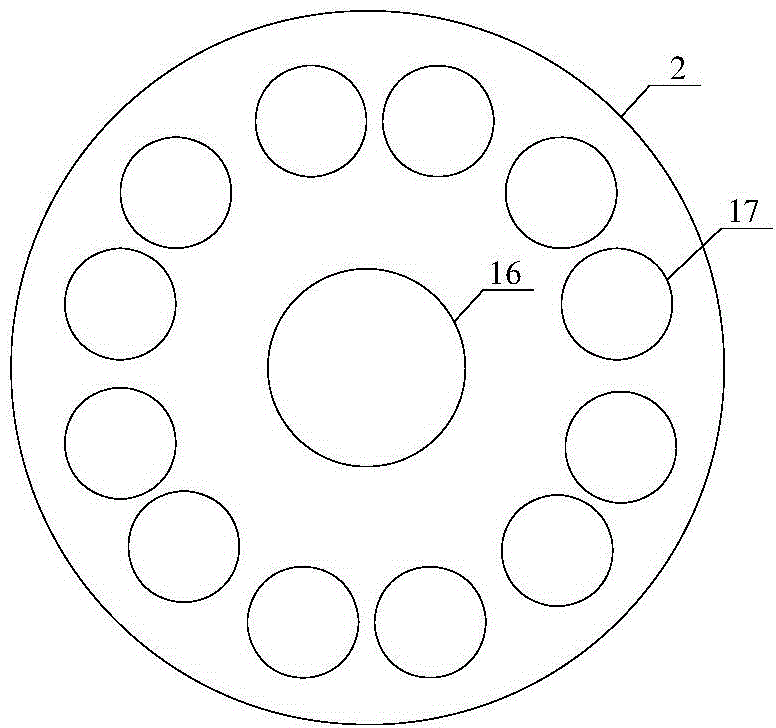

[0034] Such as figure 2 As shown, a first turntable 16 is set in the first evaporation chamber 2, and a plurality of organic material evaporation sources 17 are arranged around the first turntable 16, and the plurality of organic material evaporation sources 17 form a circle. In this embodiment, the number of organic material evaporation source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com