A Frequency Selective Surface with Switching Properties and Design Method

A technology of frequency selective surface and switching characteristics, applied in electrical components, circuits, waveguide-type devices, etc., can solve the problems of narrow working frequency band, narrow working bandwidth, complicated design, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

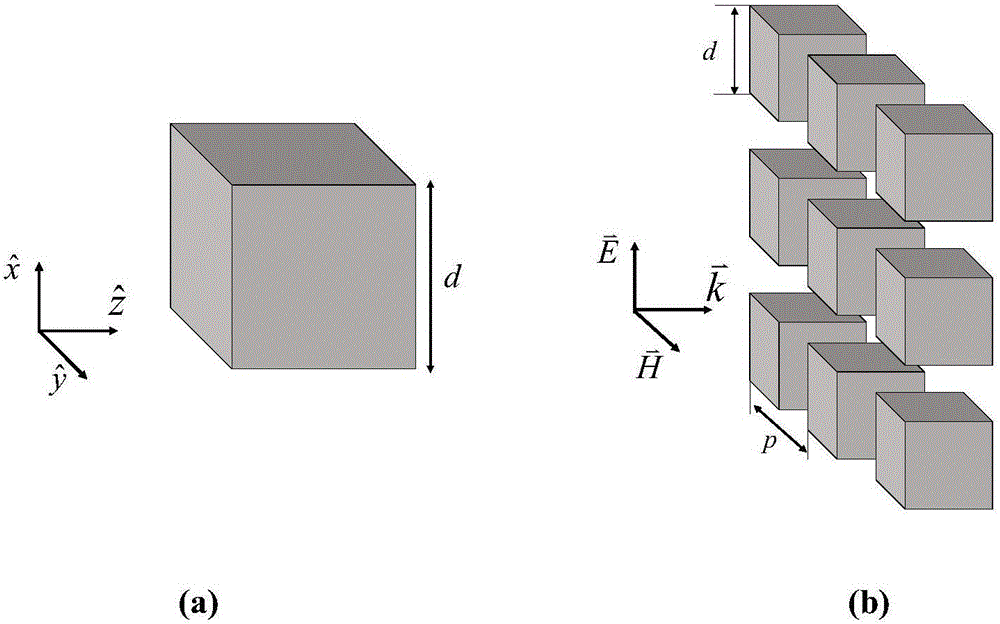

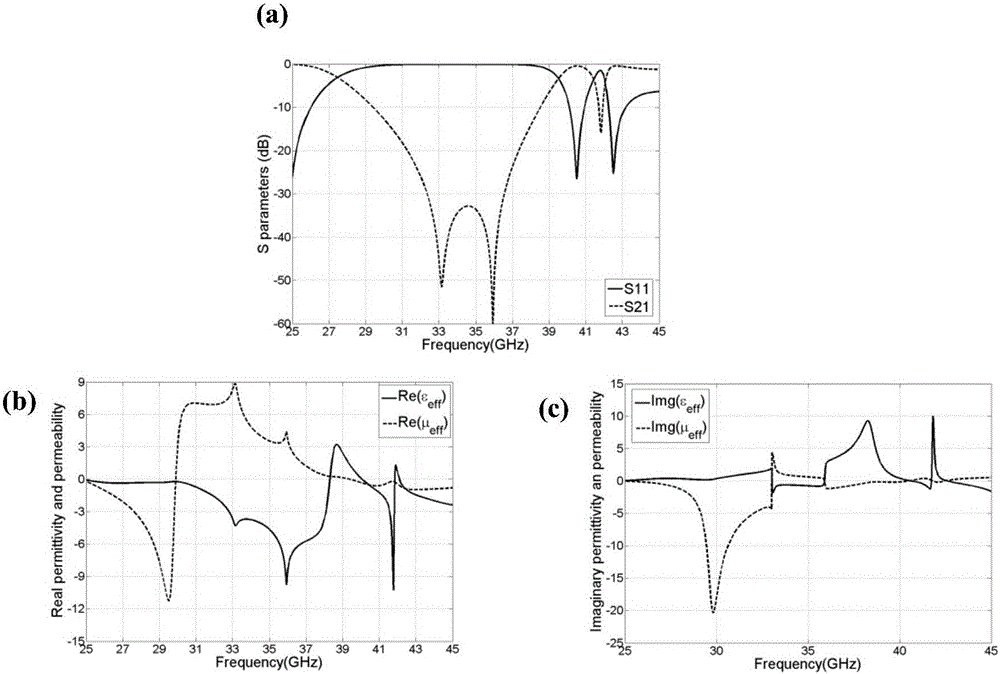

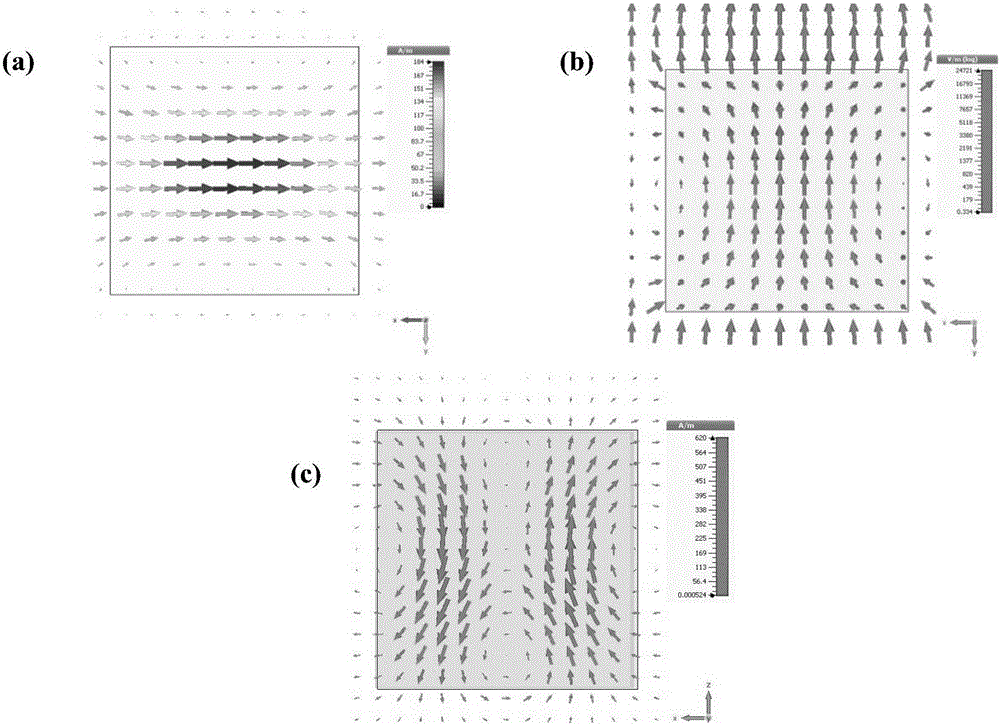

[0033] Such as image 3 As shown, the dielectric column array will produce magnetic dipole and electric dipole resonance under the irradiation of plane electromagnetic waves. It is explained by the theory of artificial electromagnetic (Metamaterial) developed around 2000 that the dielectric column array is equivalent to a single negative (Negative permeability or negative permittivity) Electromagnetic materials, when electromagnetic waves propagate in such materials, their field distribution decays exponentially and cannot propagate, and the displacement current loss in dielectric materials is very low and absorbs very little. So electromagnetic waves are almost totally reflected.

[0034] The dielectric constant (ε) of the dielectric resonator in the current THz and microwave bands r ) Can be very large, ε r Dielectric materials >100 can also be processed, which allows the dielectric column array to be made very thin in the microwave range, which can be used to prepare frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com