Negative active material for secondary battery, process for producing same, and negative electrode and lithium-ion battery both obtained using same

A negative electrode active material, silicon oxide technology, applied in the field of lithium-ion batteries, can solve the problems of insufficient productivity, insufficient capacity, and inability to fully utilize the characteristics of silicon-based materials, and achieve excellent charge-discharge capacity and cycle characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0113] Hereinafter, although an Example and a comparative example are shown and this invention is demonstrated more concretely, this invention is not limited to these Examples.

[0114] In this example, various analyzes and evaluations were performed on the silicon oxide-based composite materials, silica, and the like prepared in Examples 1 to 5, and Comparative Examples 1 and 2.

[0115] In addition, in the formula, Ph represents a phenyl group, and Me represents a methyl group.

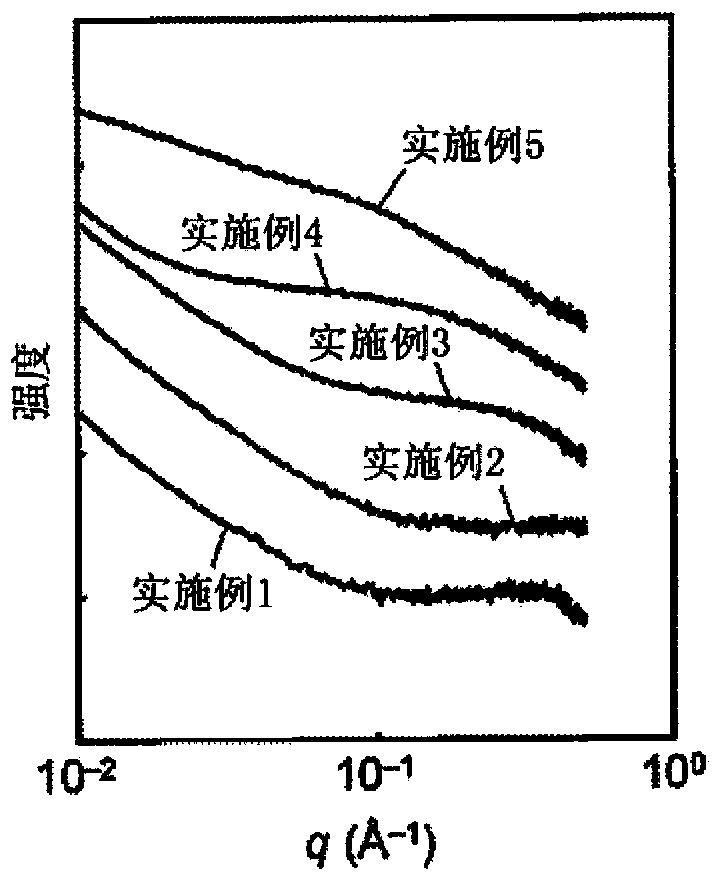

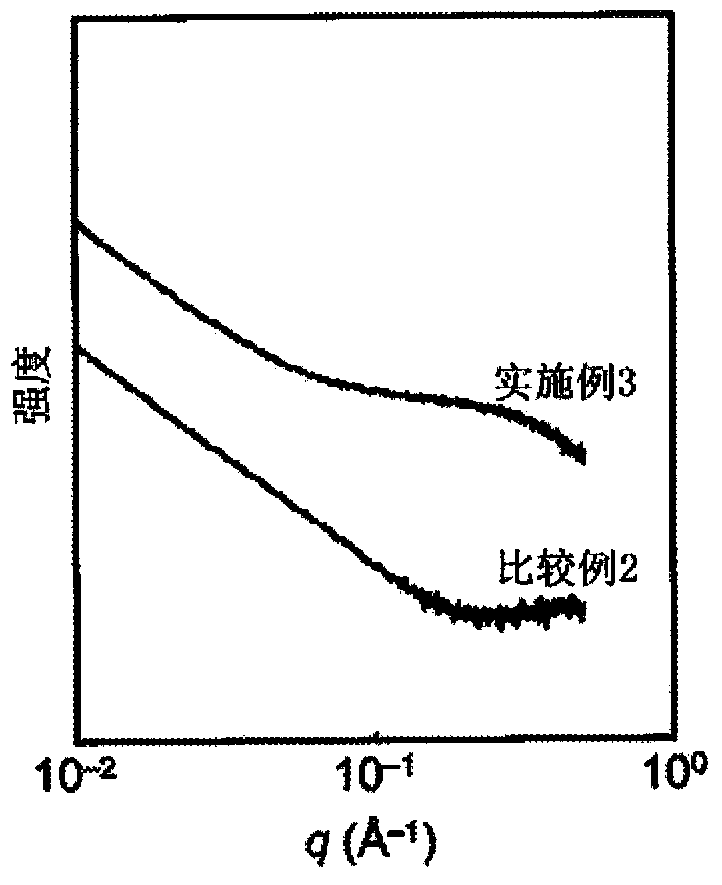

[0116] In addition, the measuring devices and measuring methods of "X-ray diffraction measurement", "elemental analysis measurement", "laser Raman spectroscopy measurement" and "X-ray small-angle scattering measurement" and "battery characteristics" in each example and comparative example evaluation", as described below.

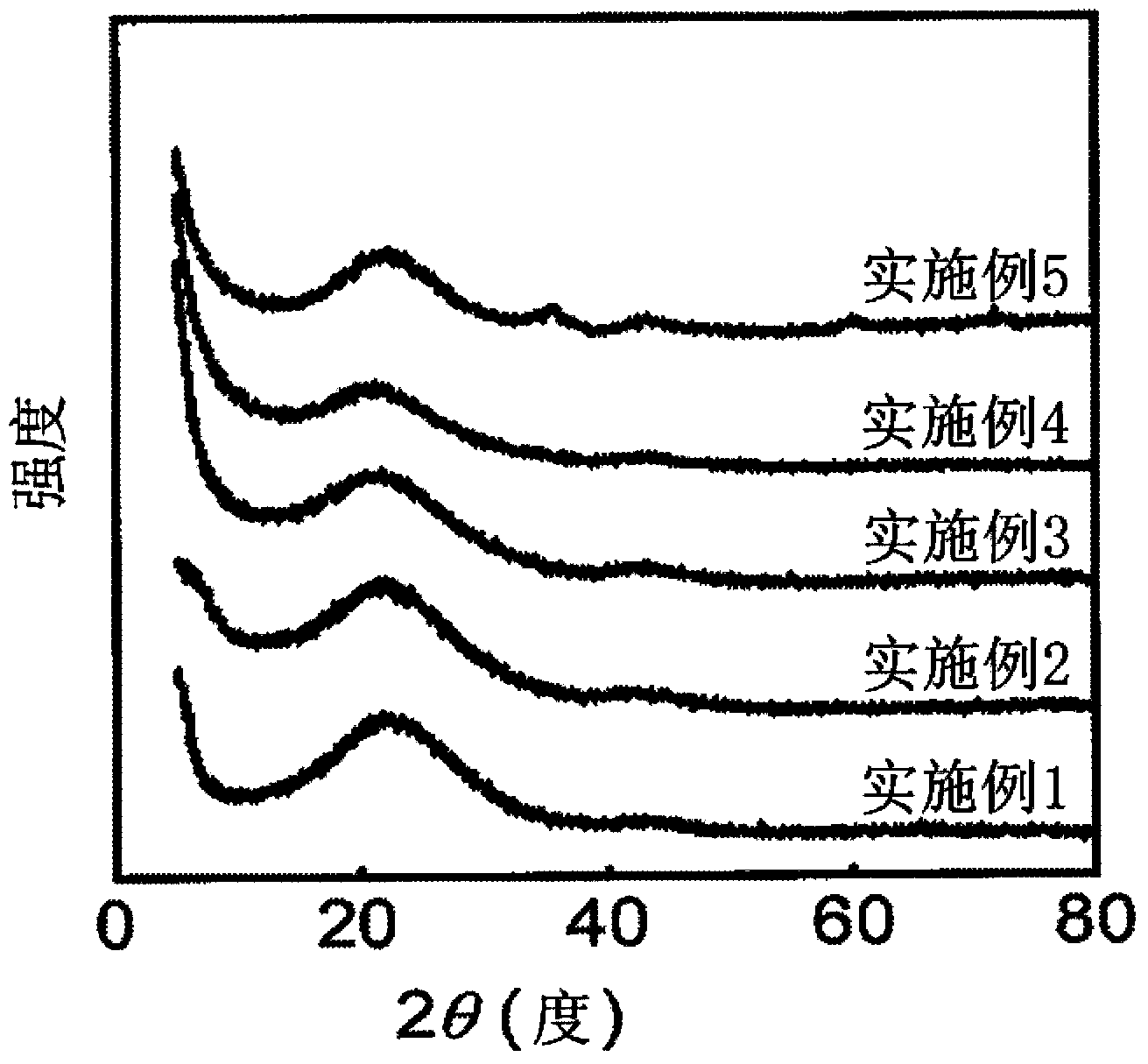

[0117] (measured by X-ray diffraction method)

[0118] X-ray diffraction is using Bruker AXS (Bruker AXS) (stock) D8 Discover as the X-ray diffraction device, by capillary metho...

Synthetic example 1

[0135] Synthesis of Octaphenylsilsesquioxane (10)

[0136]360 ml of toluene (Wako Pure Chemical Industry), 42.2 g of tetrabutylammonium hydroxide (Tokyo Chemical Industry) (37% tetrabutylammonium hydroxide (Tetrabutylammonium Hydroxide, TBAH) in MeOH), pure 16.2 g of water, stirred and cooled in an ice bath. 360 ml of diethyl ether (Wako Pure Chemical Industry) and 118.9 g of phenyltrimethoxysilane (Tokyo Chemical Industry) were put into a 500 ml dropping funnel, and were added dropwise over 5 minutes. After the dropwise addition, the ice bath was removed, and the mixture was stirred at room temperature for 70 hours. After 70 hours, filter by means of a pressure filter.

[0137] The obtained powder was transferred to a beaker, washed with toluene, and filtered under pressure again. After filtration, it dried under reduced pressure at 120 degreeC for 6 hours with the vacuum drier, and obtained 14.3 g of octaphenylsilsesquioxane (10).

Synthetic example 2

[0139] (PhSiO 3 / 2 ) n Synthesis

[0140] Into a 500 ml four-necked flask, 99.1 g of phenyltrimethoxysilane (Tokyo Chemical Industry) and 16 g of methanol (Wako Pure Chemical Industries) were charged. While stirring at room temperature, 36 g of 1N HCl was slowly added dropwise through the dropping funnel over 30 minutes. After completion of the dropwise addition, it was heated and stirred at 60° C. for 2 hours. After cooling for 2 hours, 200 g of toluene (Wako Pure Chemical Industry) was added dropwise.

[0141] Then, the reaction solution was transferred to a 500 ml separatory funnel. After washing with saturated saline, it was washed with saturated sodium bicarbonate water, then washed twice with saturated saline, and finally washed twice with pure water. After washing with water, dehydration was performed with magnesium sulfate (Wako Pure Chemical Industries, Ltd.). The liquid was moved to a separable flask, the solvent was distilled off, and heated under reduced press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com