Method for preparing concrete from solid waste, prepared concrete and method for recycling solid waste

A solid waste recycling technology, which is applied in the field of preparing concrete from solid waste, the resulting concrete, and the recycling of solid waste, can solve environmental hazards and other problems, and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

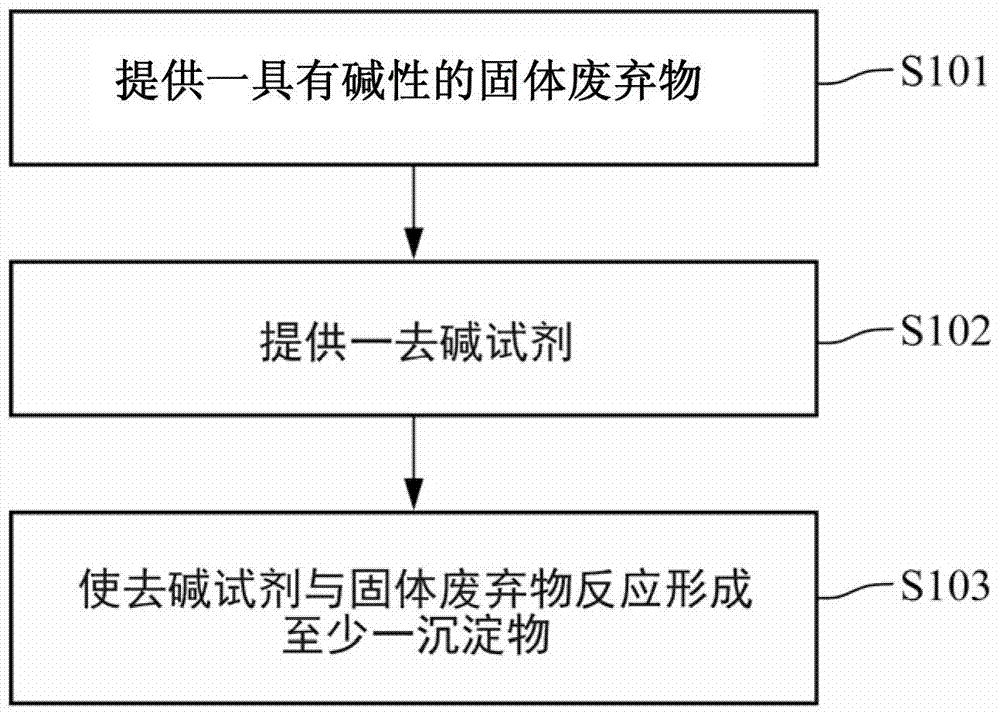

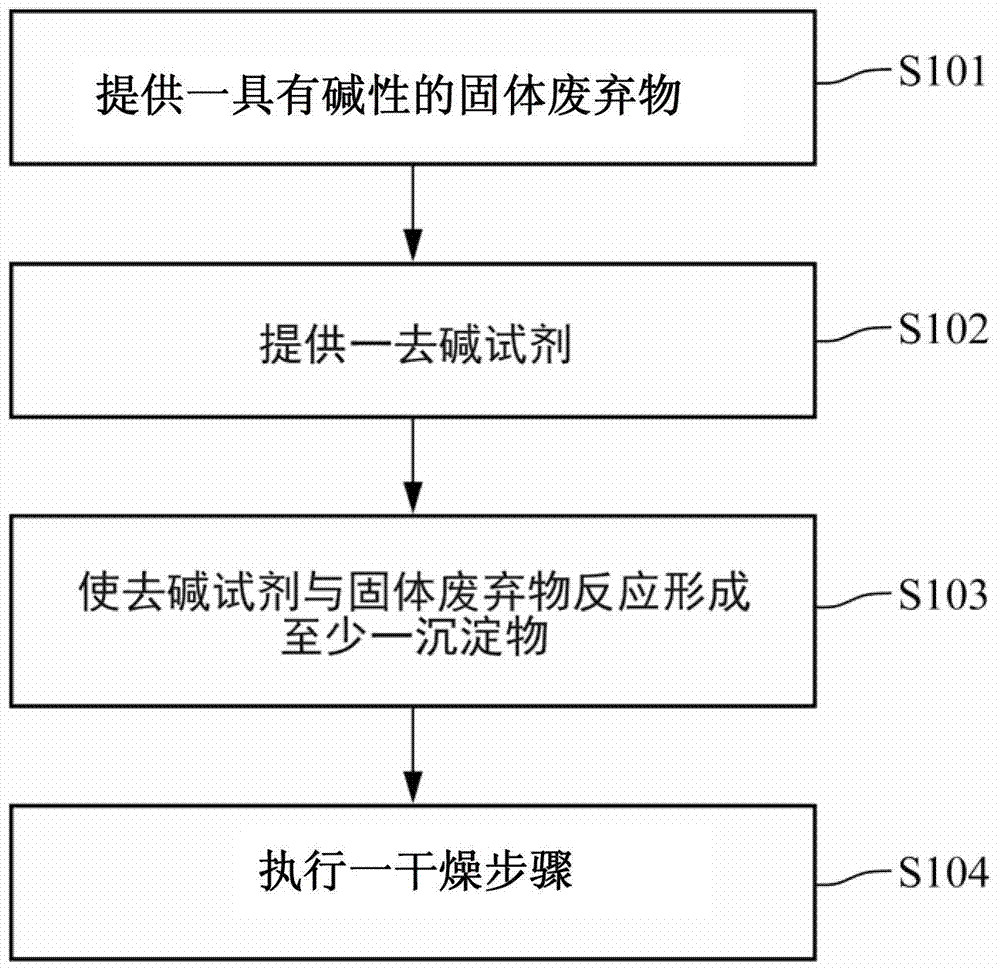

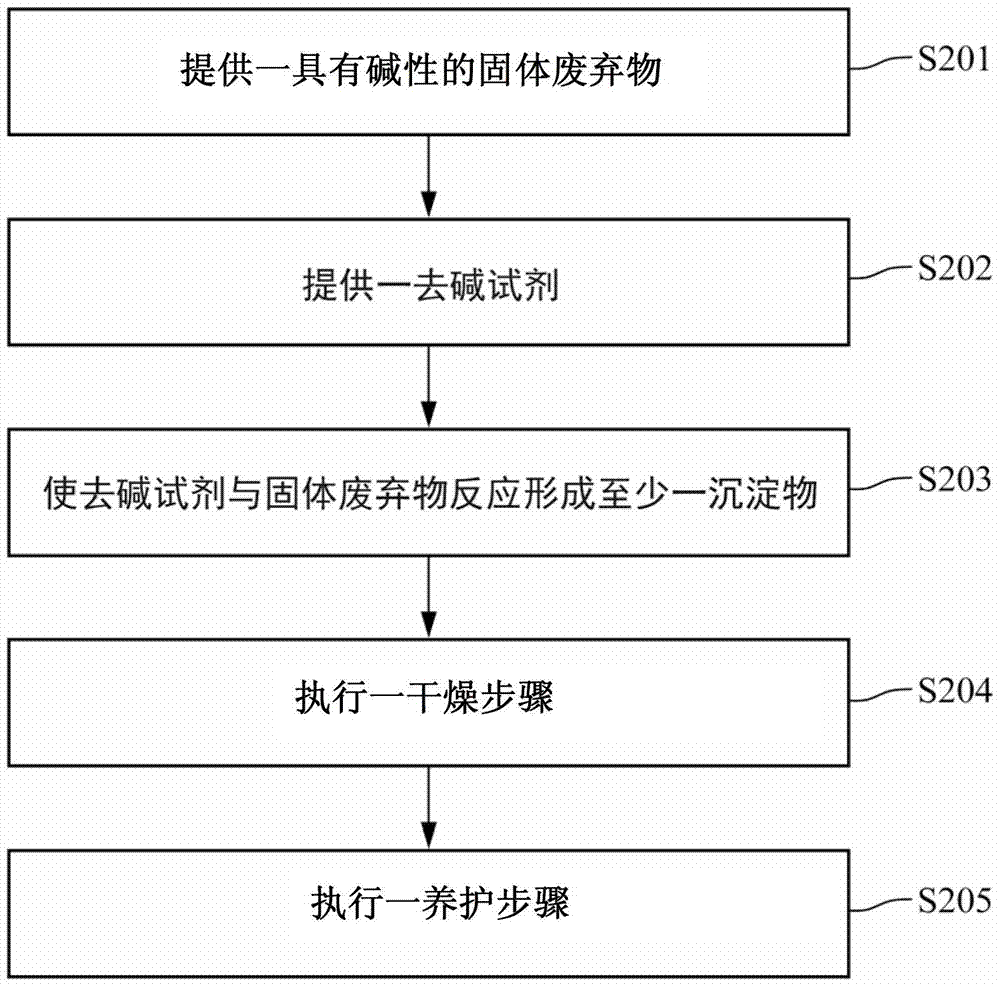

Method used

Image

Examples

Embodiment 1

[0060] First, put 1 kg of alkaline solid waste into the container. At the same time, it is measured that the pH value of the solid waste is between 12 and 13, which means that the solid waste is indeed alkaline.

[0061] Next, technical grade iron(II) sulfate (approximately 90 to 98% by weight) was added to the container. Wherein, the weight ratio of iron(II) sulfate / solid waste is between 5 and 25%.

[0062] Then, the iron(II) sulfate and the solid waste are reacted with stirring at room temperature for about 1 to 10 minutes. Thereby, iron (II) sulfate and solid waste form a mixture of reddish-brown iron (II) hydroxide and white calcium sulfate. After the reaction is completed, the pH of the mixture is between 7 and 9, so that the solid waste can be effectively de-alkalized. Such as Figure 5 As shown (solid points: 15%, hollow points: 30%), the pH value of the concrete in Example 1 has no significant change in the period up to 28 days after the reaction, which means that...

Embodiment 2

[0065] First, put 1 kg of alkaline solid waste into the container. At the same time, it is measured that the pH value of the solid waste is between 12 and 13, which means that the solid waste is indeed alkaline.

[0066] Next, technical grade dilute sulfuric acid (0.5M, 1 to 10 mL) was added to the vessel. Wherein, the weight ratio of sulfuric acid / solid waste is between 5 and 25%.

[0067] The sulfuric acid is then reacted with the solid waste with stirring at room temperature for about 1 to 10 minutes. In this way, sulfuric acid and solid waste are formed into a mixture of water and white calcium sulfate. After the reaction is completed, the pH of the mixture is between 6 and 7, so that the solid waste can be effectively de-alkalized. Such as Figure 7 As shown (15%), the pH value of the concrete of embodiment two has no significant change in the period up to 28 days after the reaction, which means that the hydroxide radicals in the solid waste have been transferred to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com