Preparation and application of a salt-free and alkali-free dyeing type reactive dye

A compound and reaction technology, applied in the direction of reactive dyes, dyeing methods, azo dyes, etc., can solve the problems of increased cost and complicated dyeing process, and achieve the effects of less sewage discharge, simple dyeing process, and low dyeing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

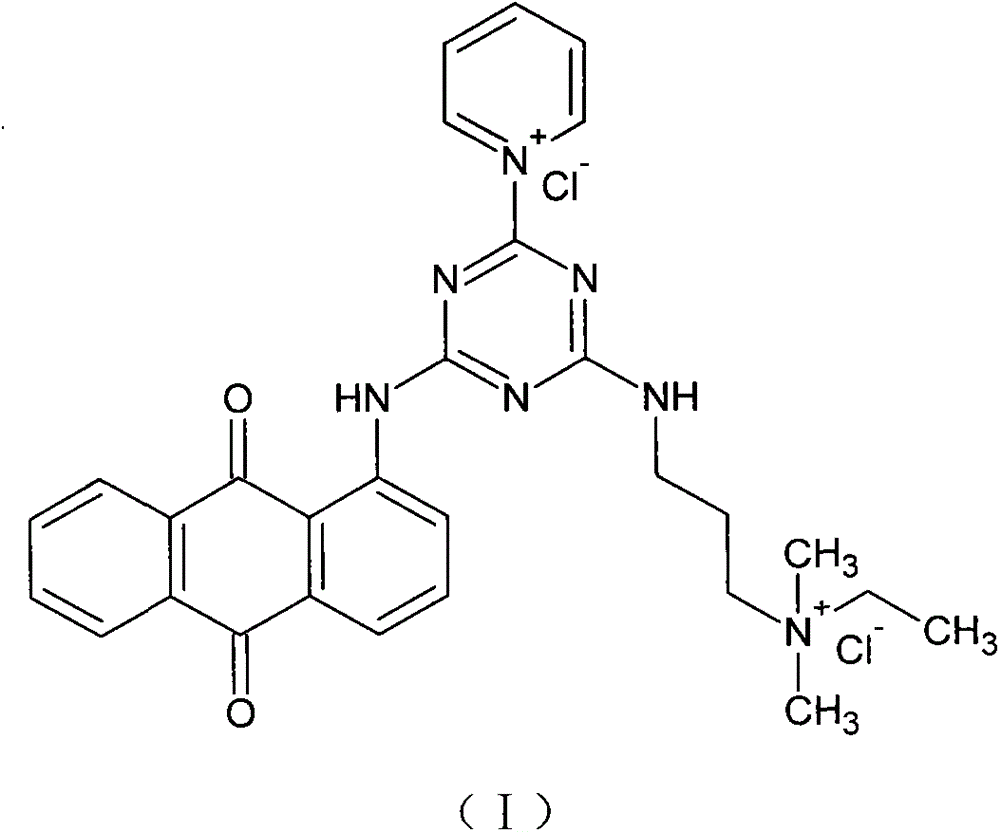

[0029] The present embodiment provides the preparation method of formula (I) compound:

[0030] The specific preparation method is as follows:

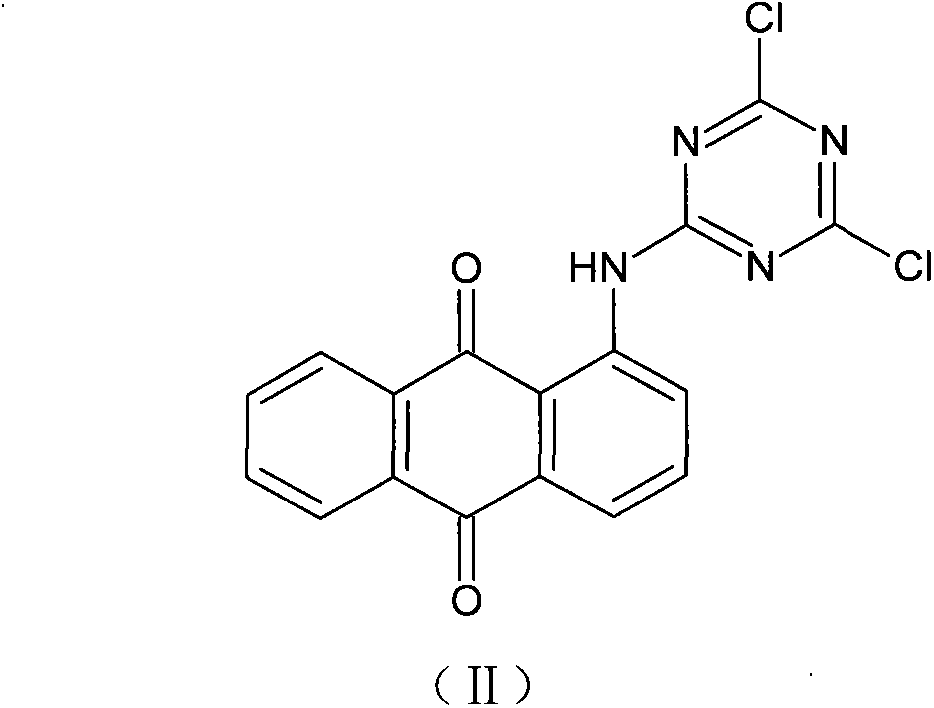

[0031] A, the synthesis of compound (II)

[0032] At room temperature, add 300mL of acetonebenzene into a 500mL three-neck flask, stir rapidly and add 11.2gl-aminoanthraquinone and 12.9g of cyanuric chloride in sequence. The reaction solution was kept at pH 5.5-6 by adding K2CO3 solution, stirred at room temperature for 10 hours, filtered, washed with acetone and petroleum ether, and vacuum-dried at 60°C to obtain 17.4 g of a khaki reaction product with a yield of 93.9%.

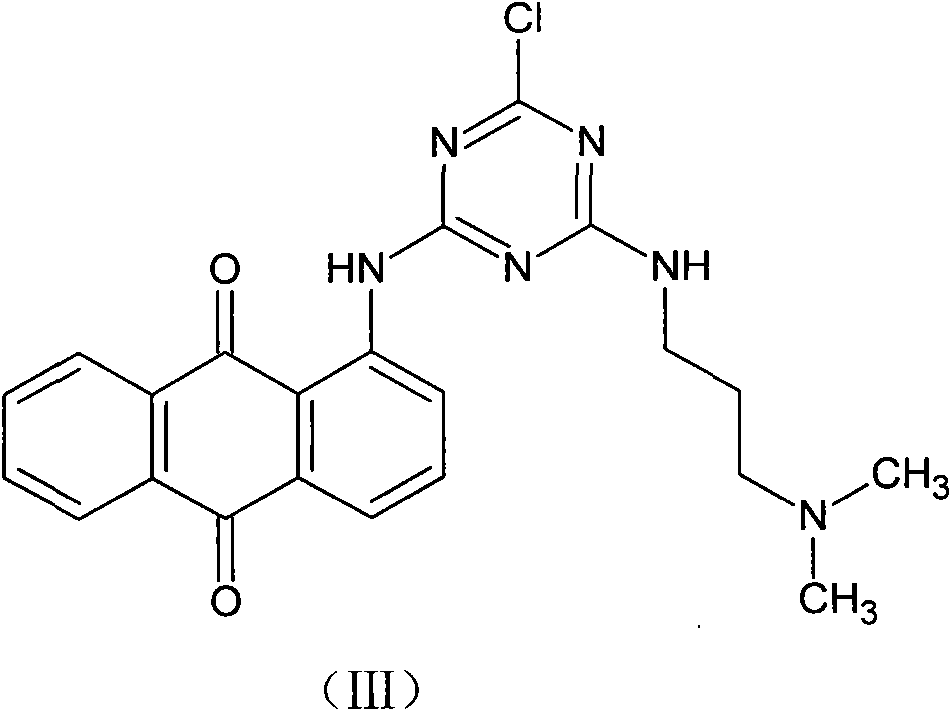

[0033] B, the synthesis of compound (III)

[0034] Dissolve 7.4g of compound (II) and 5mL of N,N-dimethyl-1,3-propanediamine in 150mL of DMF for reaction, raise the temperature to 65°C, stir and reflux for 3 hours, and rotary evaporate to obtain the crude product, dissolve the product with ethanol , filtered, and the ethanol was evaporated by rotary evaporation t...

Embodiment 2

[0042] The present embodiment provides the dyeing method of formula (I) compound to cotton fabric:

[0043] The specific dyeing method is as follows:

[0044] The dosage of compound (I) is 1.0% (o.w.f), the bath ratio is 1:50, the cotton fabric and the dye liquor are stirred and dyed at room temperature for 10 minutes, then the temperature is raised to 100°C at a rate of 2°C / min, and kept for 40 minutes. Then the cotton fabric was taken out, washed with water, soaped (2g / L soap flakes, 90°C, 5min), washed with water, dried, the dye uptake rate was 98.8%, and the color fixation rate was 77.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com