Conductive adhesive material, solar cell module, and manufacturing method for solar cell module

A technology for solar cells and manufacturing methods, applied in the directions of conductive adhesives, adhesives, adhesive types, etc., can solve problems such as breakage and warpage of solar cells, and achieve the effects of good output characteristics and high electrical connection reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach 〉

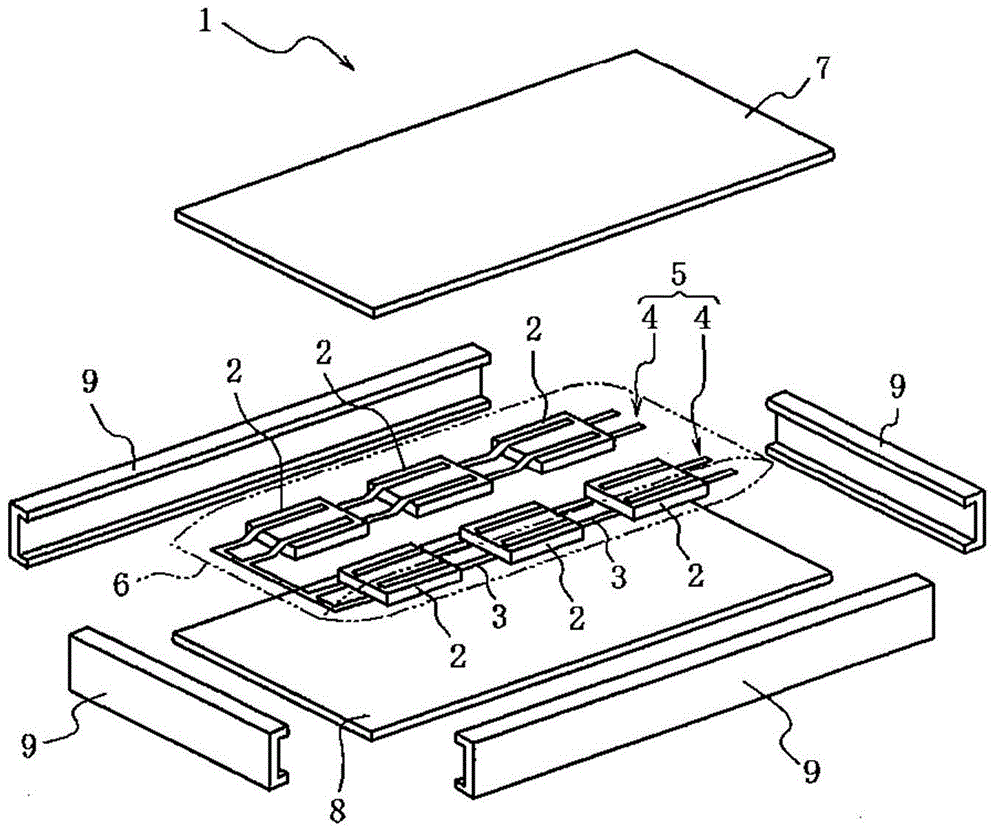

[0151] First, a first embodiment of the method for manufacturing a solar cell module of the present invention will be described as an example.

[0152] In the first embodiment of the method of manufacturing a solar cell module according to the present invention, the surface electrode of one solar cell is connected to the back electrode of another solar cell adjacent to the one solar cell by wiring through a conductive adhesive. A method of manufacturing an electrically connected solar cell module, wherein a paste-like conductive adhesive (conductive paste) is applied between the surface electrode and the wiring of the above-mentioned one solar cell, and the other solar cell The conductive adhesive is temporarily placed between the back electrode and the wiring, and the conductive adhesive is heated to be cured.

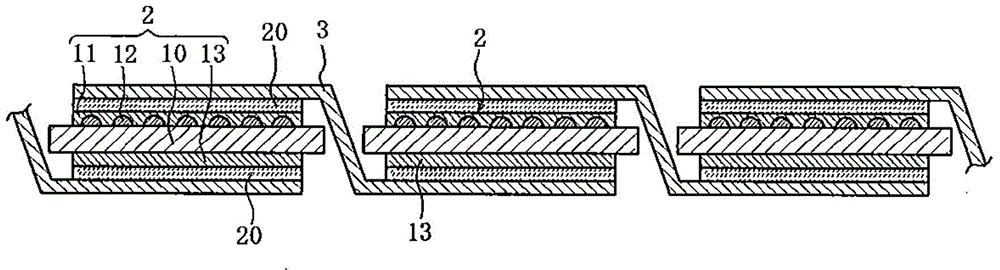

[0153] Specifically, first, Ag paste is applied on the surface of the photoelectric conversion element 10, and the finger electrode 12 and the bus bar electrode 11 ar...

no. 2 Embodiment approach 〉

[0158] Next, a second embodiment of the method for manufacturing a solar cell module of the present invention will be described as an example.

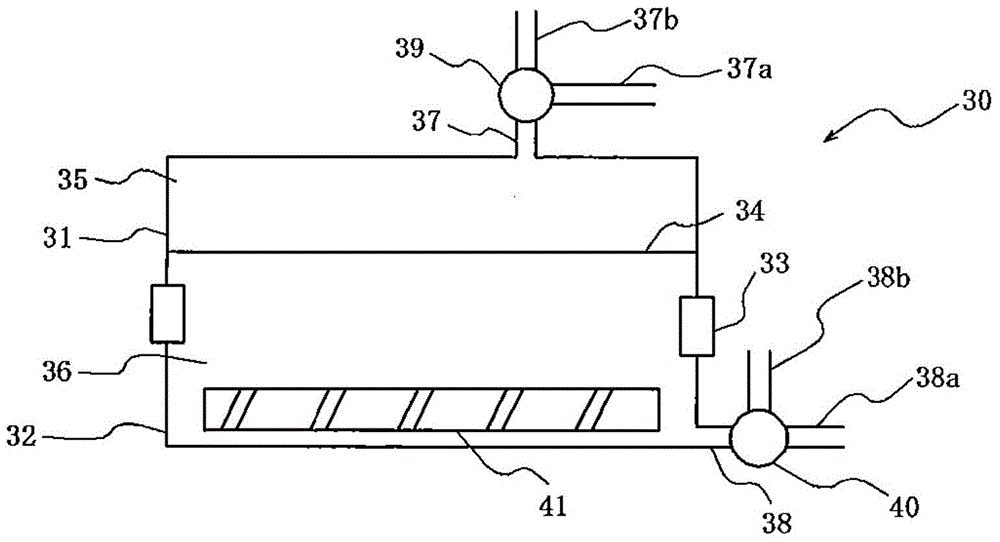

[0159] In the second embodiment of the method of manufacturing a solar cell module of the present invention, a conductive adhesive film in which a conductive adhesive is formed into a film is used for connection of electrodes and wiring. In the second embodiment of the method of manufacturing a solar cell module of the present invention, the surface electrode of one solar cell is connected to the back electrode of another solar cell adjacent to the one solar cell through a conductive adhesive. A method of manufacturing an electrically connected solar cell module, temporarily arranging a conductive adhesive film between the surface electrode and the wiring of the one solar cell and between the back electrode and the wiring of the other solar cell, Press from the top surface of the wire with a heated ram. The conductive adhesive film r...

no. 3 Embodiment approach 〉

[0163] Next, a third embodiment of the method for manufacturing a solar cell module of the present invention will be described as an example.

[0164] In the third embodiment of the method of manufacturing a solar cell module of the present invention, curing of the sealing resin and connection of electrodes and wiring are performed simultaneously. In the third embodiment of the method of manufacturing a solar cell module of the present invention, the surface electrode of one solar cell is connected to the back surface of another solar cell adjacent to the one solar cell by wiring through a conductive adhesive. A method of manufacturing a solar cell module whose electrodes are electrically connected, applying the above-mentioned paste-like conductive adhesive (conductive paste) to connect the surface electrode and wiring of the above-mentioned one solar cell and the back electrode of the other solar cell Temporarily fixed with the wiring, the sealing material and the protective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com