Base oil for refrigerated machine oil composition, refrigerated machine oil composition, composition for refrigerating, and refrigerating method

A technology for refrigerating machine oil and composition, which is applied in the field of base oil for refrigerating machine oil composition and refrigerating machine oil composition, which can solve the problems of low energy saving effect, poor compatibility of R600A, etc., and achieve low viscosity, excellent solubility, and good thermochemistry The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

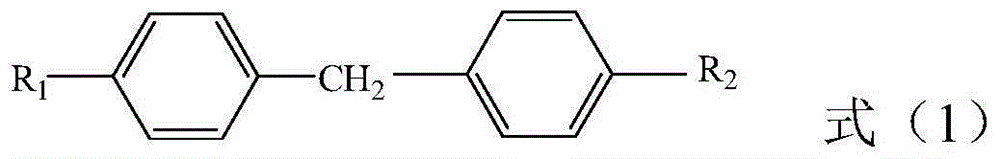

Method used

Image

Examples

preparation example Construction

[0034] The preparation of the refrigerating machine oil composition of the present invention has no special requirements, as long as the base oil for the refrigerating machine oil composition is mixed with the additives, the base oil for the refrigerating machine oil composition can be obtained first, and then mixed with the additives, or the composition can be directly refrigerated The components of the base oil for the machine oil composition are directly mixed with the additives to obtain the refrigerating machine oil composition, which is not particularly required in the present invention.

[0035] According to the refrigerating machine oil composition provided by the present invention, the additives and their contents can be various conventional additives and their conventional contents used in refrigerating machine oil compositions. For example, the additives may be lubricants for improving the lubricating performance of refrigerating machine oil, friction reducing agents...

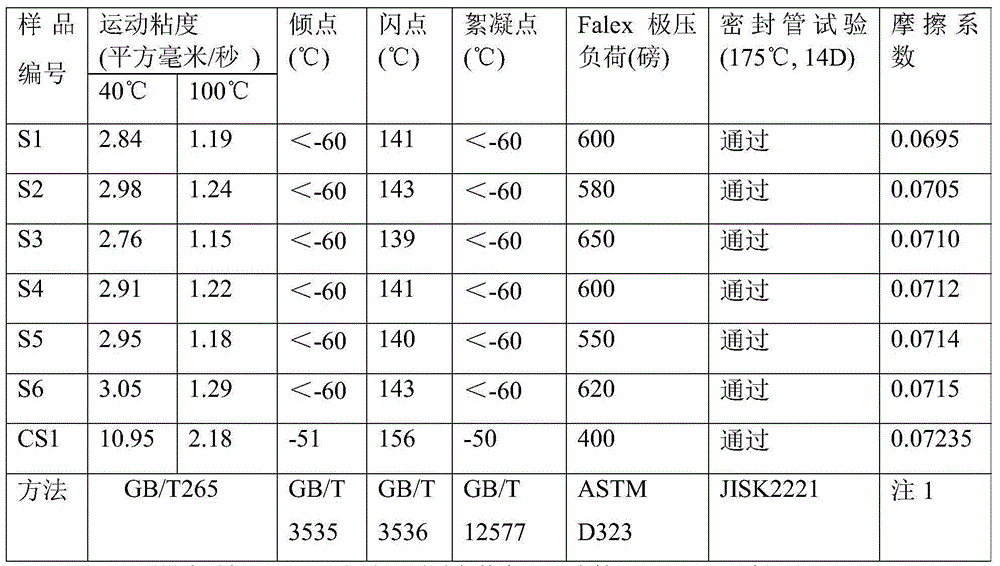

Embodiment 1

[0050] This example is used to illustrate the refrigerating machine oil composition and its preparation method provided by the present invention.

[0051] Mix benzene and hexene-1 at a molar ratio of 1.1:1, add 2% by weight (relative to the weight of benzene and hexene-1) super strong solid acid as a catalyst and react at 100°C for 2 hours, then remove the solid acid and Unreacted benzene, distill out the reaction product. The resulting product is a mixture of hexylbenzene and its isomers.

[0052] Add α-octene to a pressure-resistant reactor, inject BF3-n-butanol with a concentration of 1.5% by weight relative to 2% by weight of α-olefin as a catalyst, and polymerize at 100°C and 12 psig for 2 hours, after cooling Add water to wash and remove the catalyst, steam the reaction product, and then hydrogenate and saturate (using nickel / diatomaceous earth as a catalyst, the nickel content is 5% by weight of the total amount of the catalyst), to obtain α-octene dimers (isoparaffins...

Embodiment 2

[0055] This example is used to illustrate the refrigerating machine oil composition and its preparation method provided by the present invention.

[0056] Mix benzene and heptene-1 at a molar ratio of 1.1:1, add 1% by weight (relative to the weight of benzene and heptene-1) super strong solid acid as a catalyst, react at 130°C for 1 hour, and then remove the solid Acid and unreacted benzene, distill out the reaction product. The resulting product is a mixture of heptylbenzene and its isomers.

[0057] 80 parts by weight of benzyltoluene, 10 parts by weight of the heptylbenzene prepared above, and 10 parts by weight of α-octene dimer (the preparation method is the same as in Example 1) (the weight ratio of heptylbenzene to isoparaffin is 1: 1) Mix base oil to form a refrigerating machine oil composition, and then add 0.2 parts by weight of 2,6-di-tert-butyl-p-cresol, 3.5 parts by weight of tricresyl phosphate, 0.18 parts by weight of ethylene glycol oleate and 0.04 parts by we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com