Metallic particle paste, cured product using same and semiconductor device

A technology of metal particles and cured products, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., and can solve problems such as the difficulty of pasting metal particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The metal particle paste according to the embodiment contains a polar solvent and particles containing a first metal dispersed in the polar solvent. A second metal different from the first metal is dissolved in the polar solvent.

[0022] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

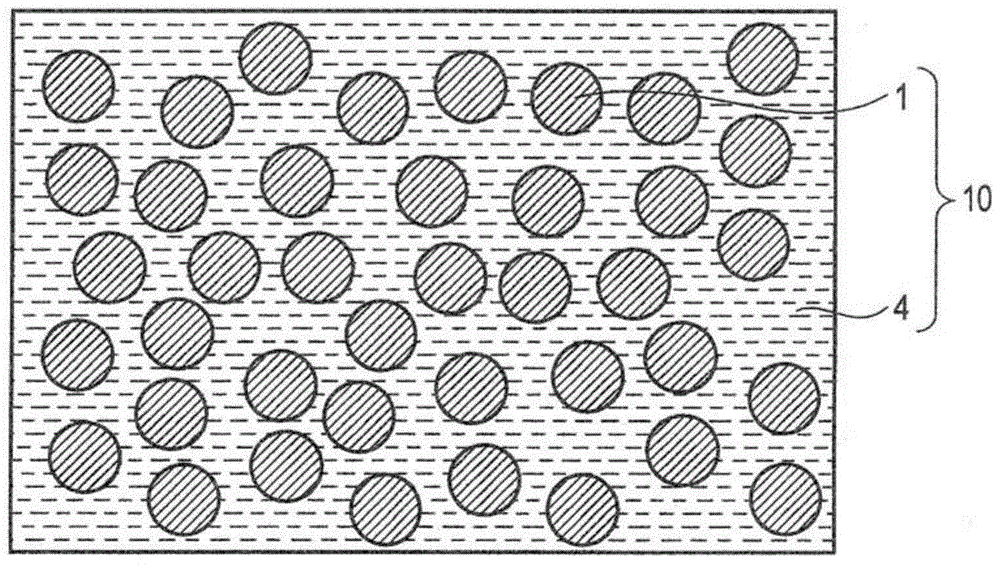

[0023] figure 1 It is a conceptual diagram of the metal particle paste concerning one embodiment. The metal particle paste 10 according to one embodiment contains two different metals, the first metal and the second metal. In the metal particle paste 10 of the present embodiment, the first metal is dispersed as the particles 1 in the polar solvent 4 , while the second metal is dissolved in the polar solvent 4 .

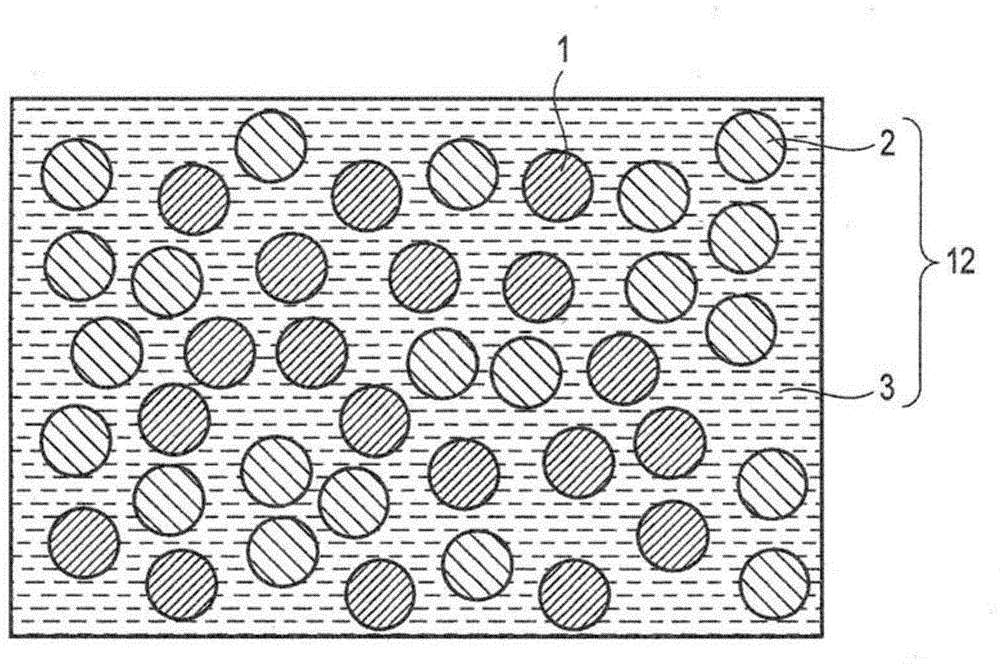

[0024] The metal particle paste of the present embodiment is cured to form a cured product in which the first metal mainly constitutes a mother phase responsible for electrical and thermal conductivity. As already explaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com